Pipeline through-wall structure and construction process thereof

A construction technique and a wall-penetrating technology, which is applied in the direction of pipes, building structures, formwork/formwork/working frames, etc., can solve the problems of reduced wall stability and achieve improved stability, improved firmness, and improved connection The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

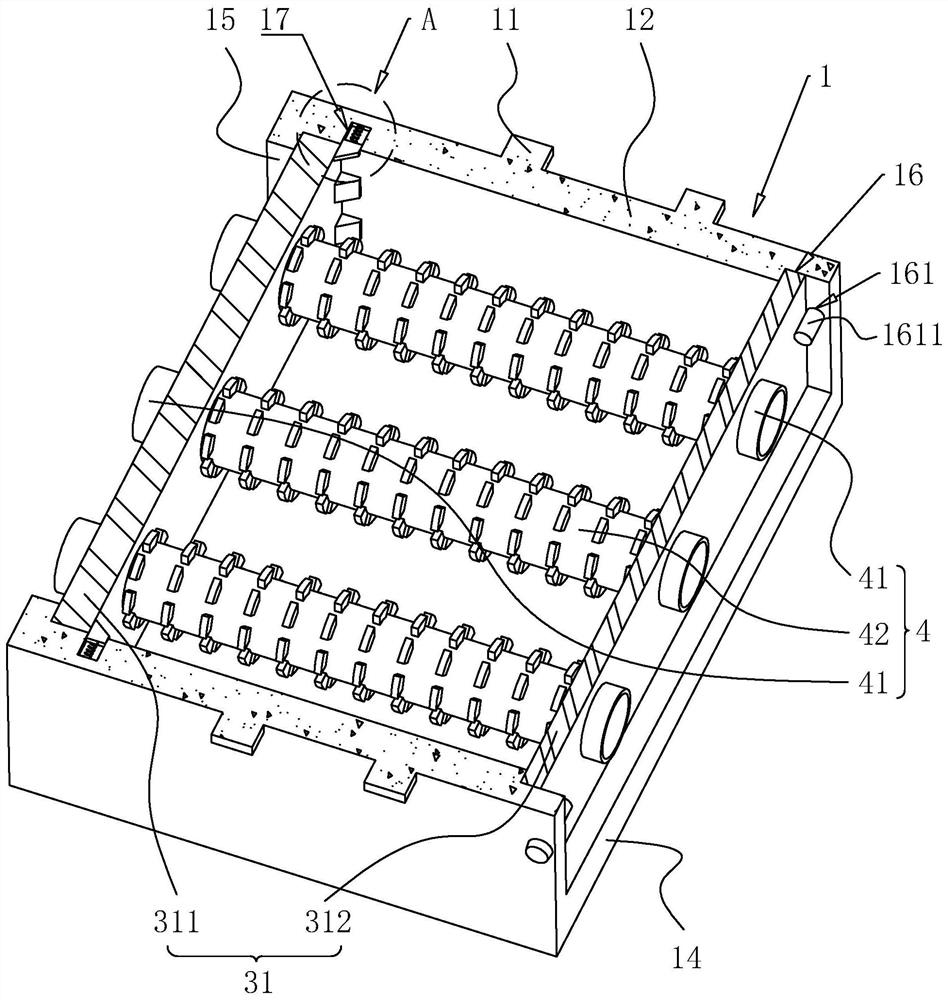

[0043] The following is attached Figure 1-4 The application is described in further detail.

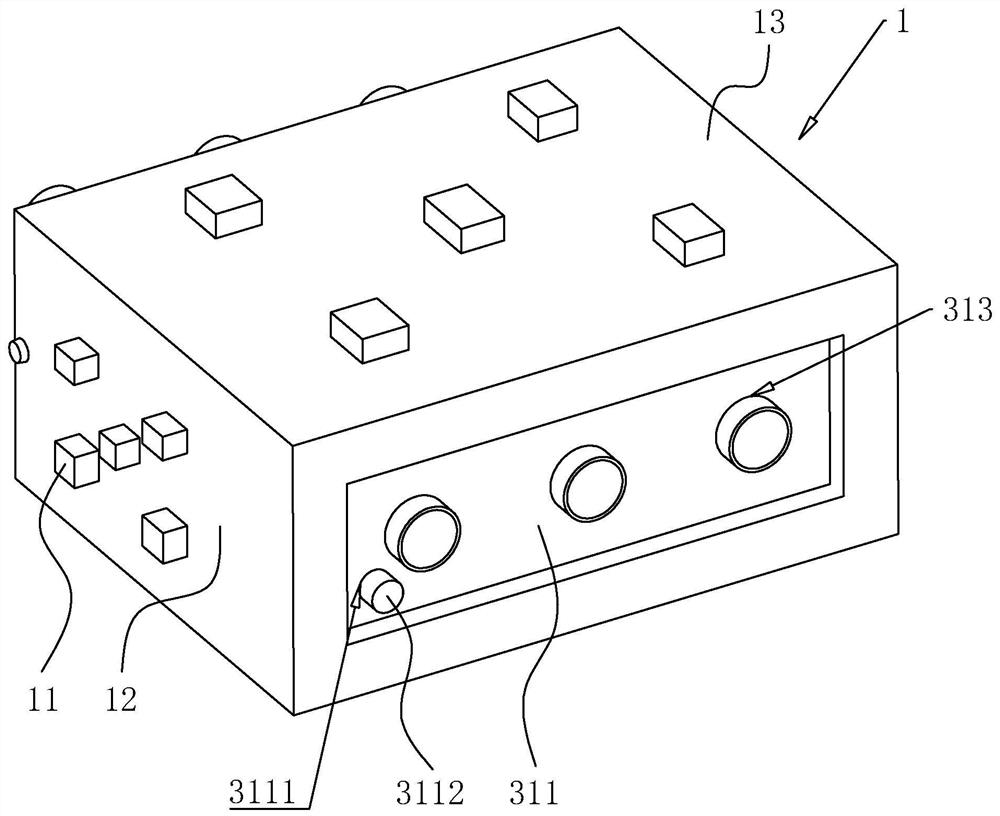

[0044] The embodiment of the present application discloses a pipe wall penetration structure. refer to figure 1 with figure 2 , A pipeline wall-penetrating structure includes a support frame 1, a plurality of limiting components 2, a sealing component 3 and a plurality of wall-penetrating pipelines 4, and in this embodiment there are three wall-penetrating pipelines 4.

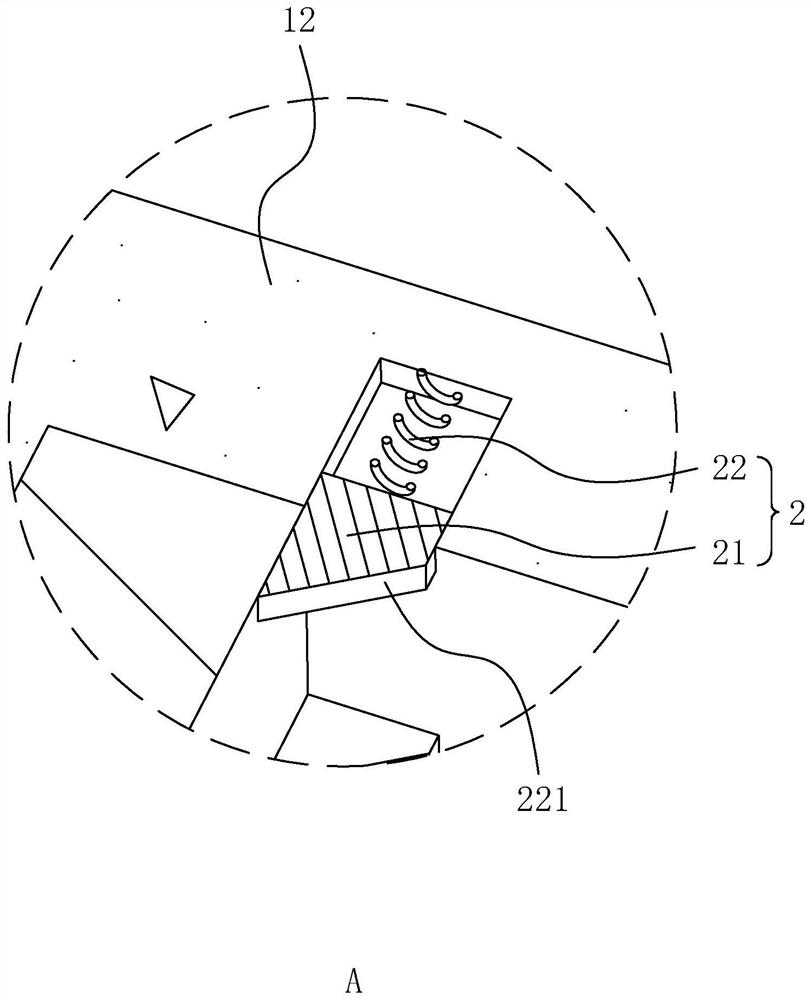

[0045] refer to figure 1 with figure 2, the support frame 1 is a rectangular frame, the outer wall of the support frame 1 is welded with a plurality of protrusions 11, and the support frame 1 includes two vertical side plates 12, a horizontal top plate 13 and a horizontal bottom plate 14 , the bottom wall of the top plate 13 is set obliquely downward from any side plate 12 to the other side plate 12; the inner wall of any opening end of the support frame 1 is welded with a retaining ring 15, and the end face o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com