Bag-type dust collector with prepositioned cyclone separator

A bag filter and cyclone technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of small vibration and deformation, affecting the dust removal effect, and dust falling off, and achieve smooth sliding. , Enhance the effect of jitter frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

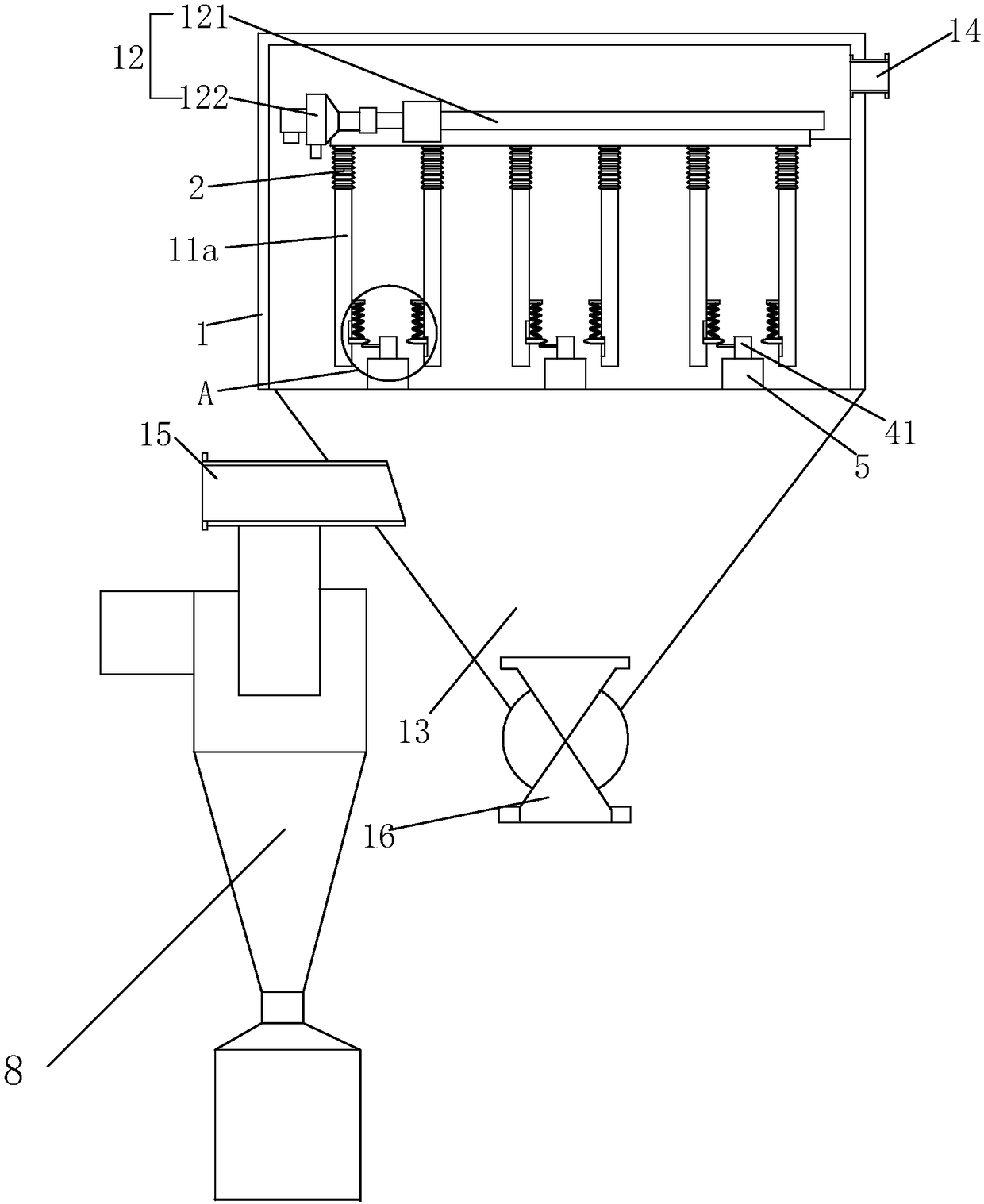

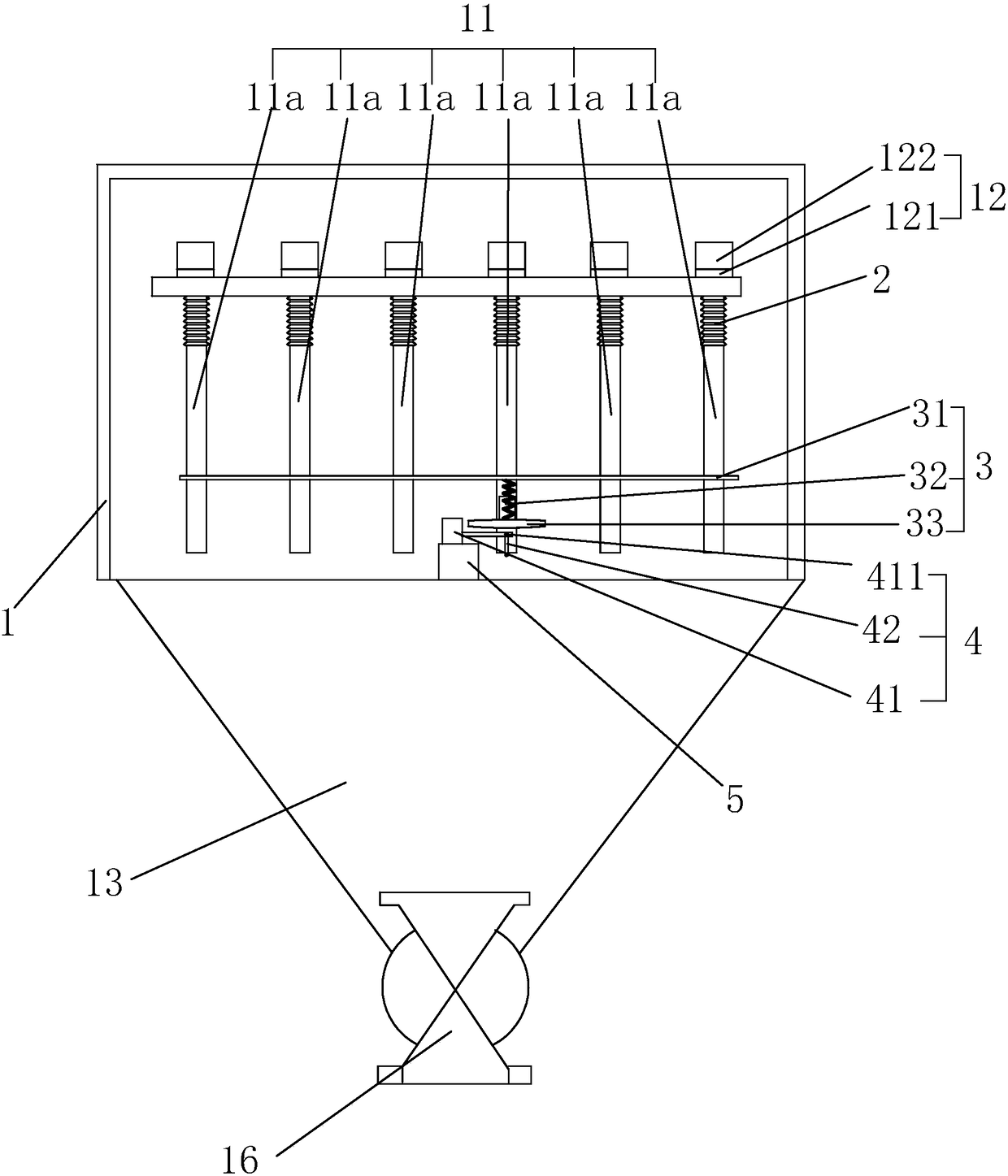

[0036] Embodiment 1: a kind of bag filter of front cyclone dust collector, as figure 1 with 3 Shown, mainly comprises body 1, is provided with a plurality of filter elements 11a in body 1, and filter element 11a is arranged in the body 1 in row-and-column array, is positioned at the top of filter element 11a in body 1 and is provided with cleaning control system 12, cleaning The control system 12 mainly includes a blowing pipe 121 fixedly arranged on the top of the filter element 11a in the body 1, and the blowing pipe 121 is provided with an electromagnetic pulse valve 122. At this time, a plurality of filter elements 11a arrayed in a direction perpendicular to the blowing pipe 121 are defined. Form a group of filter components 11; in the body 1, there is an ash hopper 13 for dust storage under the filter element 11a, and there is a clean gas outlet 14 for clean gas discharge above the gas cleaning control system 12, and the ash hopper 13 The side wall of the ash hopper is p...

specific Embodiment approach

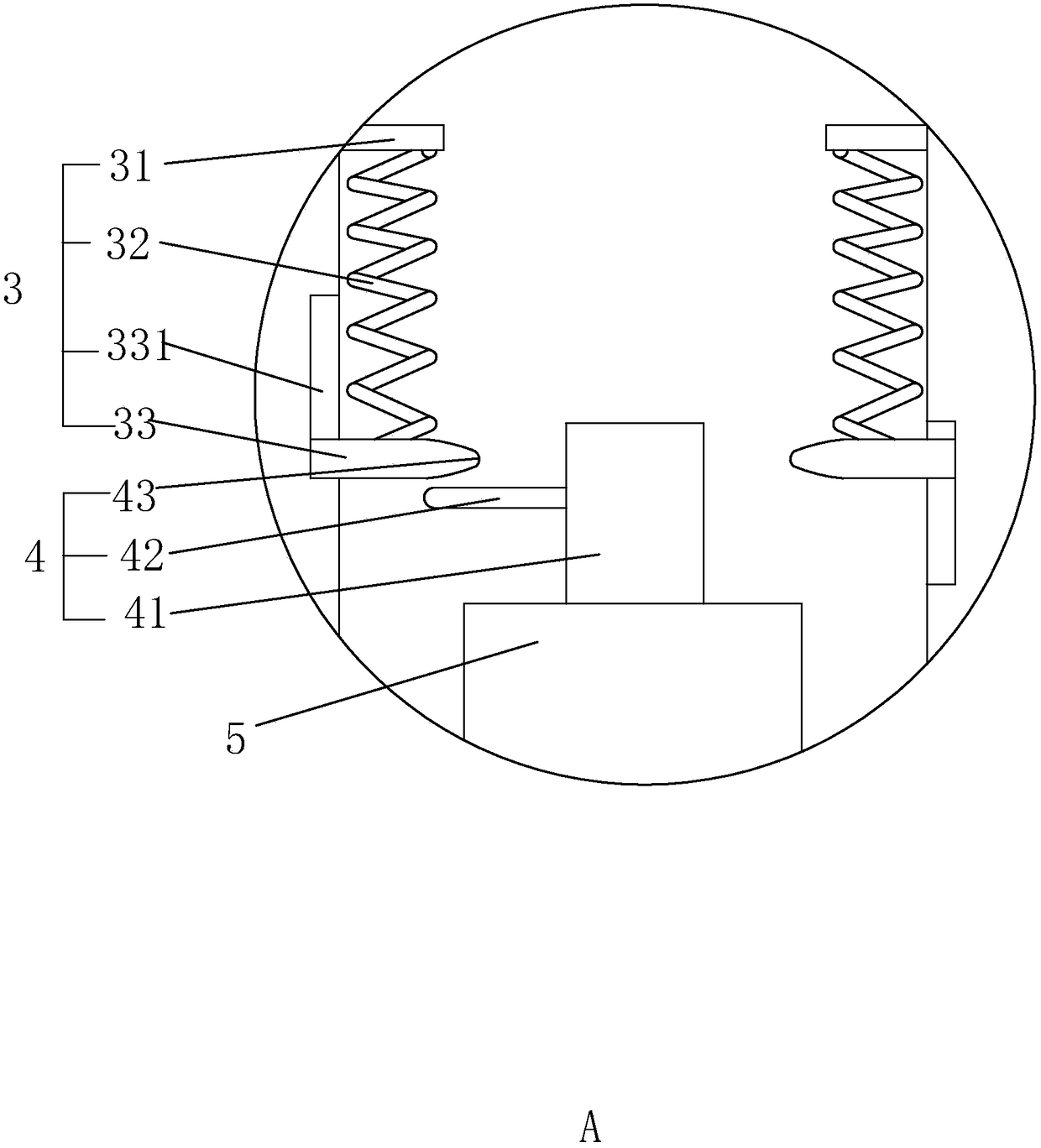

[0040] Specific implementation method: when the filter core 11a accumulates more dust near the middle and lower parts and cannot fall smoothly under the work of the dust removal control system 12, the driving motor 41 is controlled to work, the output shaft 411 rotates, and drives the circumference of the working rod 42 Rotate, when the working bar 42 rotates to conflict with the sliding working plate 33, it will drive the upward movement of the sliding working plate 33, because the width of the sliding working plate 33 is slightly longer than the connecting plate 31, so the working bar 42 and the sliding When the working plate 33 interferes, it will not interfere with the connecting plate 31; the sliding working plate 33 makes the telescopic spring 32 compressed during the upward sliding of the filter element 11a, because the working rod 42 moves away from it when it rotates with the output shaft 411. The running track of one end of the output shaft 411 is circular, so the end...

Embodiment 2

[0043] Embodiment 2: a kind of bag filter of front cyclone dust collector, the difference with embodiment 1 is, as Figure 4 with 5 As shown, the connecting plate 31 is provided with a limit mechanism 6 that controls the vertical vibration of the filter core 11a; the limit mechanism 6 includes an extension rod 61 that is fixedly arranged on the sliding work plate 33 and is perpendicular to it, and on the extension rod 61 A stop bar 62 perpendicular to it is fixedly provided, a stop slot 63 for the stop bar 62 to slide up and down is provided on the support plate 5, and a connection fixed to the support plate 5 is fixedly provided at the bottom of the extension bar 61 The spring 64, in order to prevent the limit rod 62 from sliding up and down in the limit groove 63, will conflict with the wall of the limit groove 63 and cause wear, so at this time, the outer circumferential surface of the limit rod 62 is wrapped with a protective cushion 621 .

[0044] Specific embodiments: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com