Stenter setting machine dust removal belt anhydrous cleaning device

A stenter setting machine and cleaning device technology, applied in the direction of dust removal, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as inability to remove, pollute the working environment on site, and affect the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

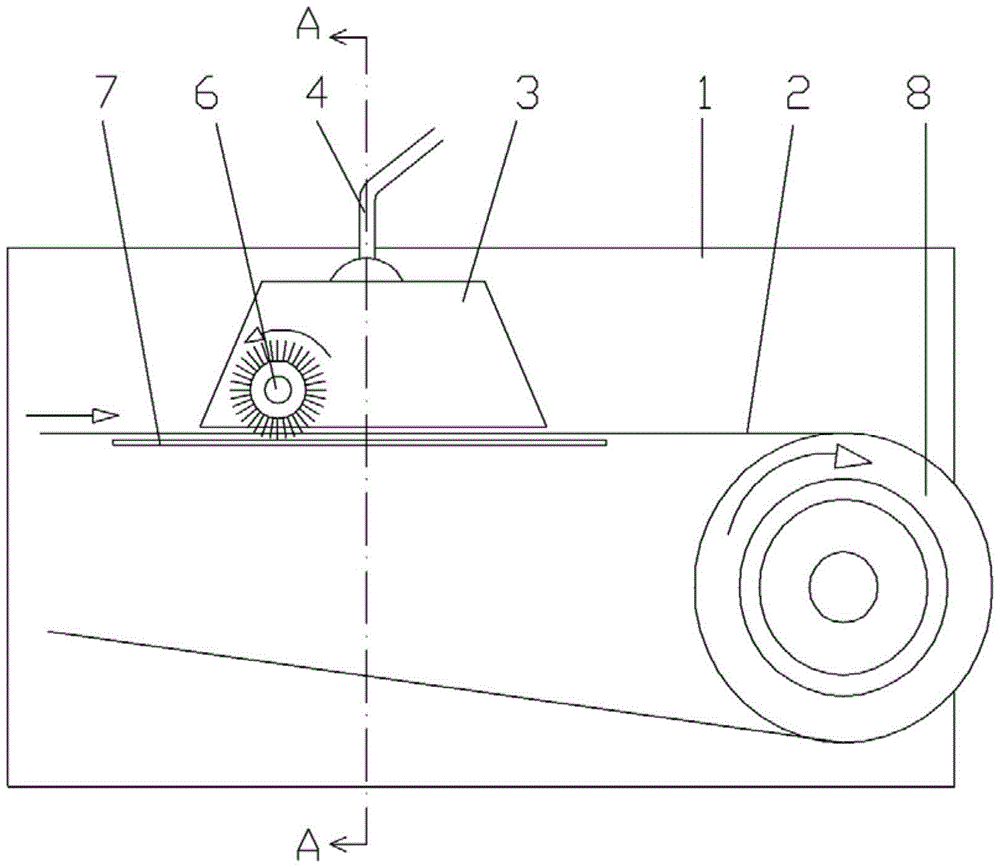

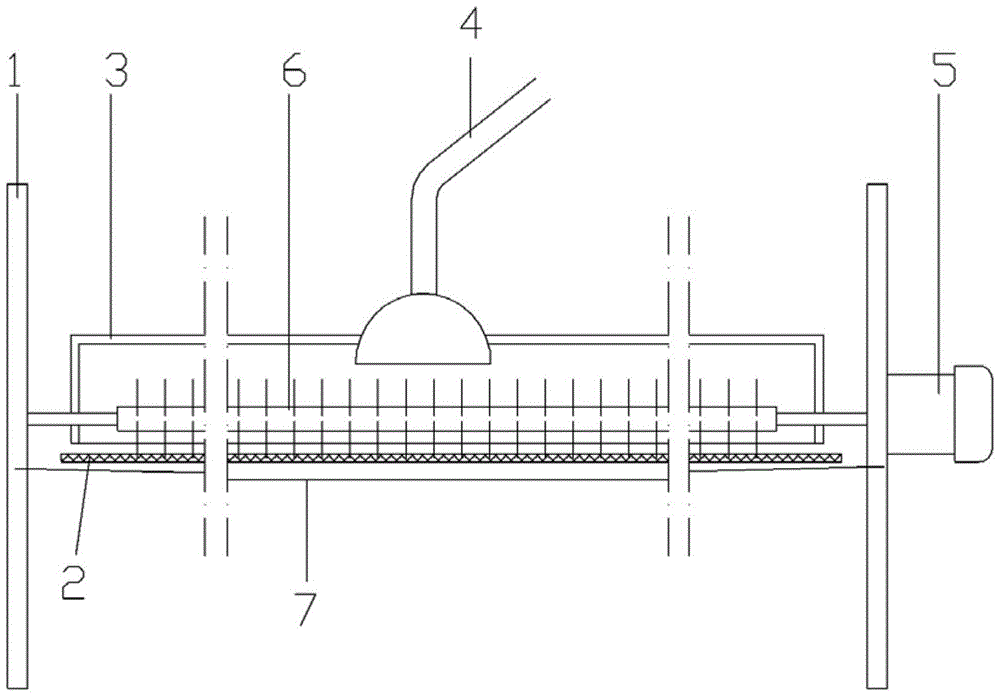

[0014] Example: see figure 1 , 2 As shown, the anhydrous cleaning device for the dust removal belt of the stenter setting machine includes the frame 1 and the dust removal belt 2 of the stenter setting machine, and the dust suction cover 3 is placed above the dust removal belt 2 and fixed on the frame 1. 3 is connected with a negative pressure suction pipe 4, and the motor 5 drives the brush roller 6 to rotate. The two ends are respectively fixed on the frame 1 and placed under the dust removal belt 2, and the adhesive tape 7 is opposite to the dust suction hood 3.

[0015] The motor 5 is fixed on the frame 1, and the roller shaft of the brush roller 6 passes through the preset hole on the dust suction hood 3.

[0016] The distance between the lower surface of the dust collection cover 3 and the upper surface of the dust removal belt 2 is less than 5mm, and the distance between the upper surface of the adhesive tape 7 and the dust removal belt 2 is 5-10mm.

[0017] The dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com