Cleaning system for selection plating product developing process

A cleaning system and product technology, applied in the field of cleaning systems, can solve problems such as poor hole breakage, hinder copper plating, and inability to remove scum, and achieve the effect of avoiding unclean cleaning and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

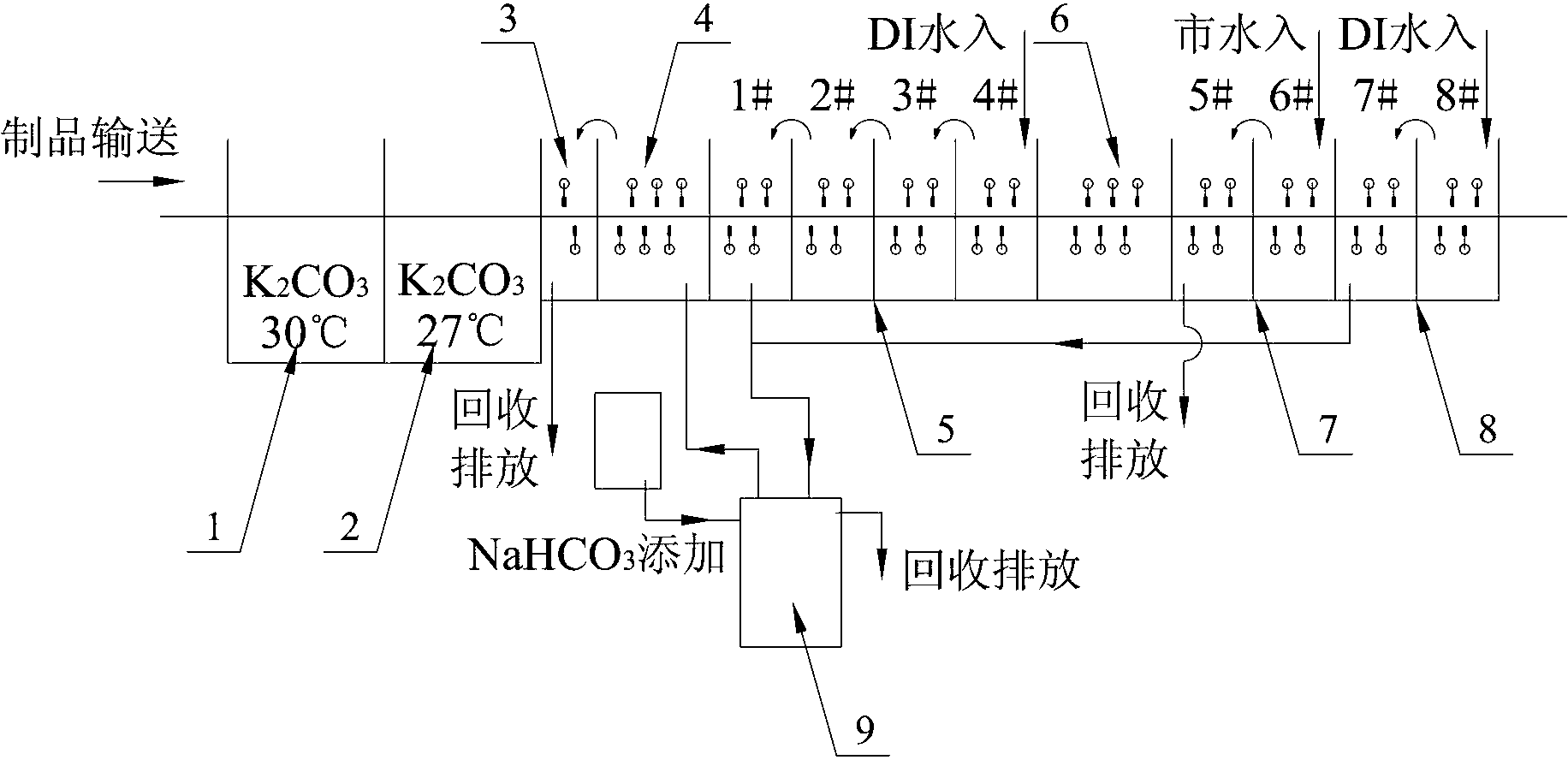

[0024] Embodiment one: see attached figure 2 As shown, a development process cleaning system for selectively plated products is used for cleaning flexible printed circuit boards during the development process of pattern electroplating.

[0025] The cleaning system for the development process of selective plating products includes from front to back (that is, attached figure 2 From left to right in the middle), there are developing tank containing developing solution, discharge washing tank 3 with double-sided spraying device, neutralizing tank 4 containing neutralizing liquid, and front tank containing deionized water. Washing tank 5, the cleaning tank 6 that holds the sodium bicarbonate cleaning solution and the back washing tank that holds water.

[0026] Specifically, the developer tank includes the No. 1 developer tank 1 and the No. 2 developer tank 2 from front to back, and the developer contained therein is potassium carbonate solution. The temperature of the potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com