Steel truss girder multi-point traction type incremental launching construction system and construction method thereof

A steel truss girder and jacking construction technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems that the construction of steel truss girders cannot be carried out stably, the soil quality of the foundation does not meet the construction needs, and affects the construction speed of the project. Achieve safe and reliable installation quality, avoid excessive force on a single point, and solve the effect of high-speed traffic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

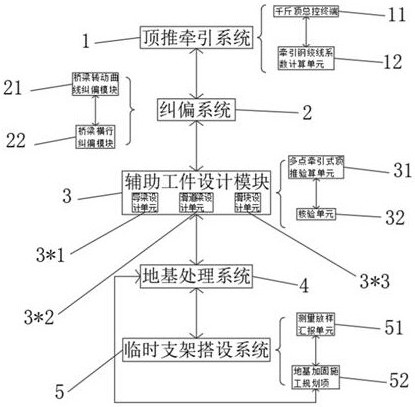

[0057] The steel truss girder multi-point traction type jacking construction system of this embodiment, such as figure 1 shown, including;

[0058] The jacking traction system 1 is used for the general traction control of the steel truss beam project, the allocation of equipment, and the subcontracting delivery of engineering tasks, including the jack general control terminal 11 and the traction strand coefficient calculation unit 12:

[0059] The jack master control terminal 11 is used to control multiple continuous jacks to move forward synchronously, to provide a power source for the steel truss beam, and to reach the design coordinates;

[0060] The traction strand coefficient calculation unit 12 is used to calculate the optimal number of traction strands, and is responsible for connecting each jack to ensure consistent operating speed;

[0061] The deviation correction system 2 is used to maintain the error and dislocation during the traction and pushing process of the m...

Embodiment 2

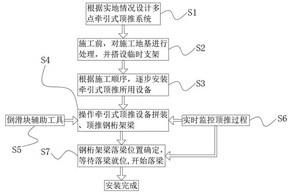

[0095] The multi-point traction type jacking construction method of the steel truss girder in the present invention comprises the following steps:

[0096] S1: The team used the multi-point traction jacking construction system to discuss and design a specific construction plan according to the actual situation at the construction site;

[0097] S2: Carry out on-site exploration of the construction site geology before construction, and carry out adaptive reinforcement treatment on it, and erect temporary supports on the surface of the reinforced foundation as required for operators to use;

[0098] S3: According to the construction sequence, install the traction-type jacking equipment on the support in sequence;

[0099] S4: Issue instructions on the control platform to control the traction jacking equipment to assemble the steel truss beams and adjust the jacking displacement;

[0100] S5: Set guide sliders on the bracket to ensure the stable operation of the traction jacking...

Embodiment 3

[0112] Such as figure 2 As shown, the formula for calculating the foundation bearing capacity of the jacking bracket is:

[0113]

[0114] In the formula: N is the maximum single pile support reaction force of 157.3T in the temporary pier during the dragging process (B, C, D temporary pier load combination 4)

[0115] Ad is the area of the pole base Ad=80cm×80cm=6400cm2;

[0116] According to the consideration of the most unfavorable load, the coefficient of bearing capacity of the foundation is taken as 1.0, and the bearing capacity of the concrete foundation under the bottom support of the vertical pole is:

[0117] N / Ad=157.3×10^4 / 6.4×10^5=2.46MPa<[f]=9.5MPa, the bearing capacity of the foundation under the bottom bracket meets the requirements.

[0118] The bottom bracket is located on the 1.0mC20 concrete layer, calculated according to the force transmission area (concrete is calculated according to the divergence angle of 45 degrees, and can be fully diffused to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com