Method of prestressed steel wire mesh polymer mortar reinforcing concrete ribbed arch bridge

A prestressed steel strand and reinforced concrete technology, applied in bridge reinforcement, bridge, bridge construction, etc., can solve the problems of rib arch bridge without reinforced concrete, column concrete damage, concrete honeycomb, etc., to improve bearing capacity and flexural rigidity , small changes in appearance size and shape, and obvious reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

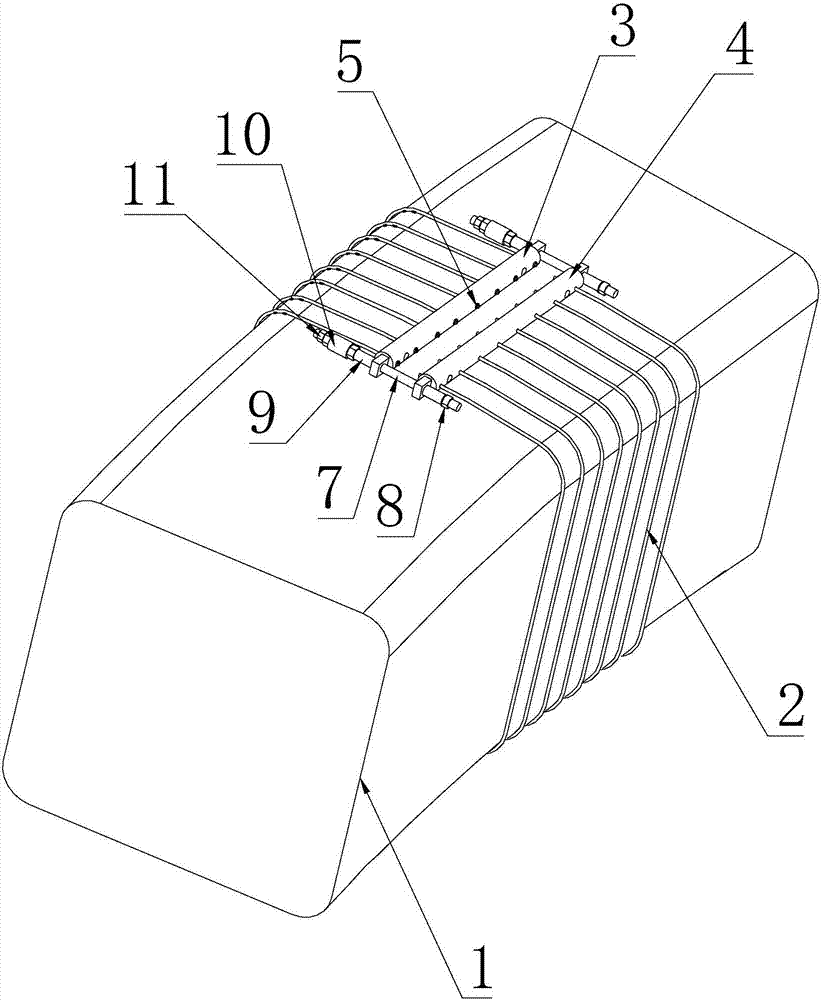

[0065] The bridge adopts a ribbed arch structure, the span of the main arch ring is 48.0m, the net sag is 6m, the bridge deck is 7m wide, and the design load is 20 for cars and 120 for trailers. The design of the main arch ring - the rectangular arch rib 1 of equal cross-section is adopted, the rib height is 1.0m, and the width is 2.0m. It is a double-rib structure. Due to the increasing traffic load, the arch rib 1 arch foot, the arch top, and 1 / 4 of the arch rib are cracked.

[0066] For the actual situation of the bridge and the requirements of the owner, our team adopted the self-developed prestressed steel strand mesh 2-polymer mortar reinforcement method for the whole bridge reinforcement design.

[0067] 1. Steel bar length value

[0068] by the formula

[0069]

[0070] Since the bridge is a flat arch, take the larger value; Lg=2.67m. Considering the simplicity of construction, the length of the steel bar is adjusted to 2.0m in actual construction.

[0071] 2. T...

example 1

[0081] Example 1: Strength Test of Confined Concrete Axial Compression Members

[0082] The key point of improving the bearing capacity of the hoop-prestressed steel strand mesh 2 to the reinforced concrete arch rib 1 is to increase the concrete strength in the press zone, so a set of hoop-prestressed steel strand mesh 2 is designed to constrain the prime concrete column axis Pressure performance test.

[0083] Component design: 150mm×150mm×450mm, the concrete strength is C25, and the reinforcement spacing is 37.5mm. A total of 5 component tests are carried out, one of which is a comparative unreinforced specimen. The experimental variable is the prestress level, which is 0, 10%, 20%, and 30%, respectively.

[0084] test results:

[0085]

[0086] It can be seen from the above table that the concrete strength of the reinforced member has been significantly improved, and the improvement range increases with the increase of the prestress level. It is verified from the compo...

example 2

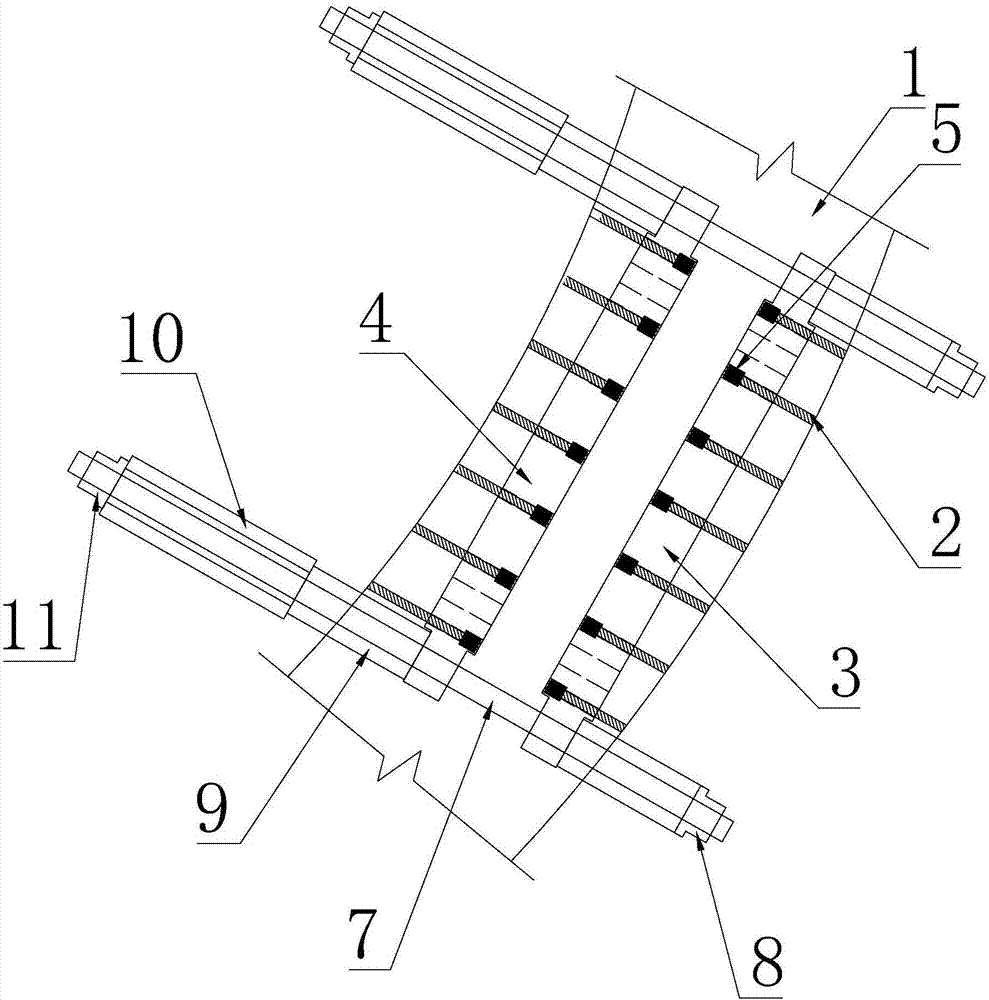

[0087] Example 2: Structural test of arch rib 1

[0088] arch rib 1 design

[0089] like Figure 5 As shown, the span m of the arch rib 1 is 3500mm, the height n is 700mm, the span loss ratio is 1 / 5, the cross-sectional size of the arch rib 1 is 150mm×150mm, and the pouring concrete strength is C25. The main reinforcement adopts HPB235 steel bar with a diameter of The stirrup is made of HPB235 steel bar with a diameter of The stirrup spacing is 130mm, and the concrete cover thickness is 25mm.

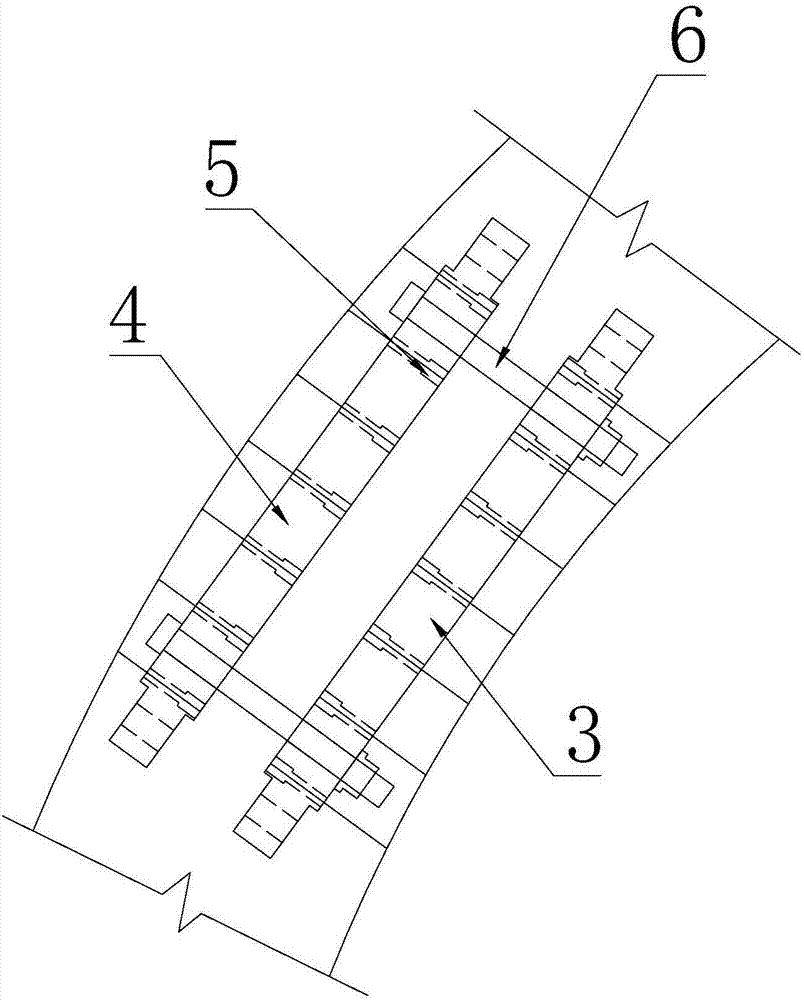

[0090] Reinforced design:

[0091] The arch rib 1 is reinforced for the whole bridge, and the prestressed steel strands with a spacing of 37.5mm are arranged in the circumferential direction. The tension degree of prestress is 20% of the tensile strength of the steel strands. mm galvanized steel wire rope.

[0092] test results:

[0093]

[0094]

[0095] The test results prove that this reinforcement method is also very effective for the reinforcement of the actual reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com