Steel-structure truss high-altitude arc sliding installing method

An installation method and steel structure technology, applied in the direction of building construction, construction, construction material processing, etc., to achieve the effects of cost saving, obvious economic benefits, and rapid sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

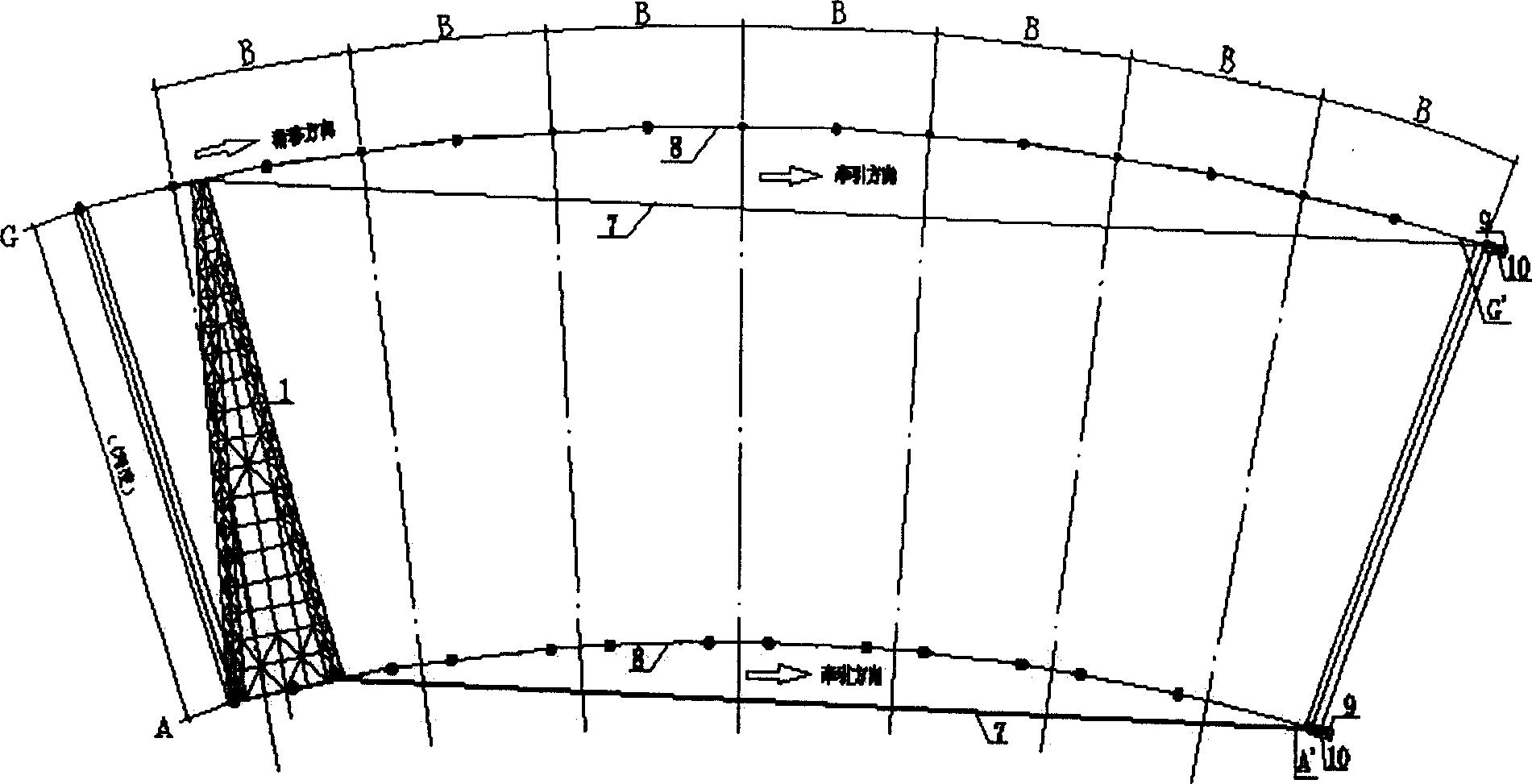

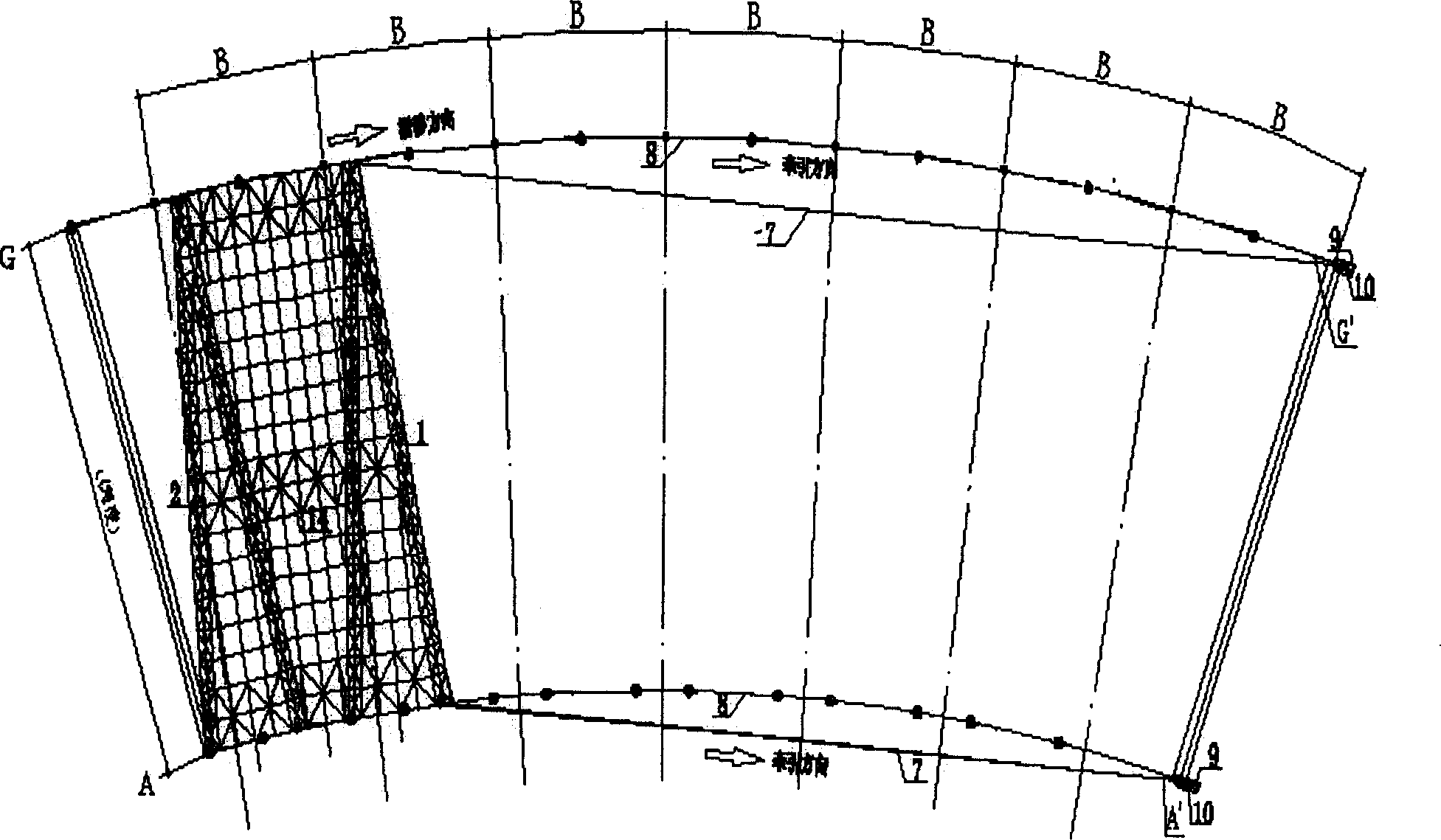

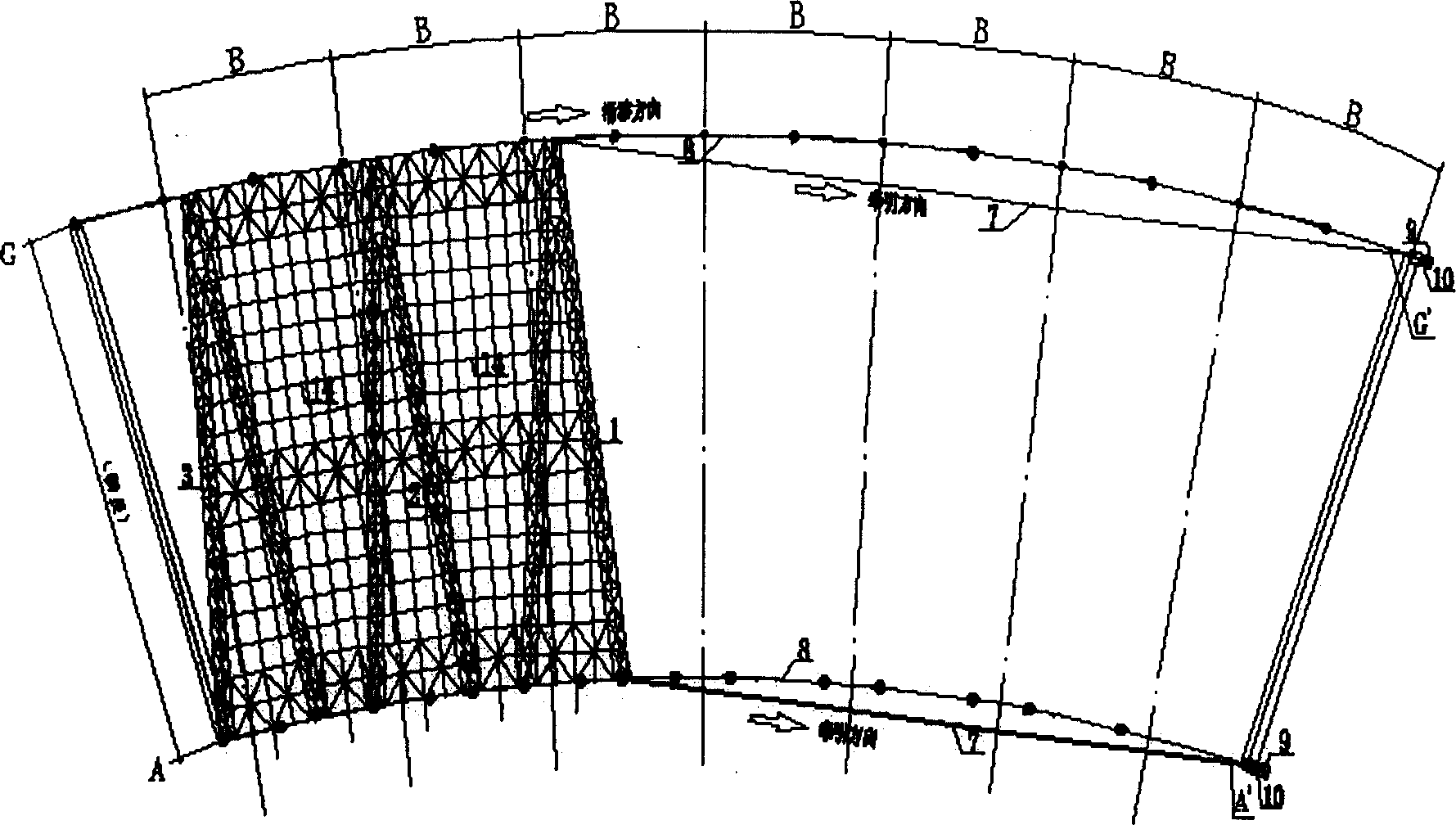

[0019] The construction area of an airport waiting hall is about 30,900 square meters. The plane is fan-shaped. The upper chord length of the fan shape is 197m, the lower chord length is 154m, and the span is 72m. The plane is divided into two areas, B and C. The plane is Y-shaped, with a total of 6 pieces, and each piece weighs about 82T. The main trusses are connected by curved rectangular beams and ray beams. The on-site installation of the steel roof of the waiting hall adopts the high-altitude arc sliding construction technology. The two ends of the truss are supported on two concentric arcs, and the lengths of the two slideways are 127 meters and 206 meters respectively. The slideway is the most important load-bearing member in the sliding of the truss, and the slideway plays the role of load-bearing guide and laterally limiting the horizontal displacement of the slide plate during the entire horizontal traction. The slideways are arranged on the arc-shaped sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com