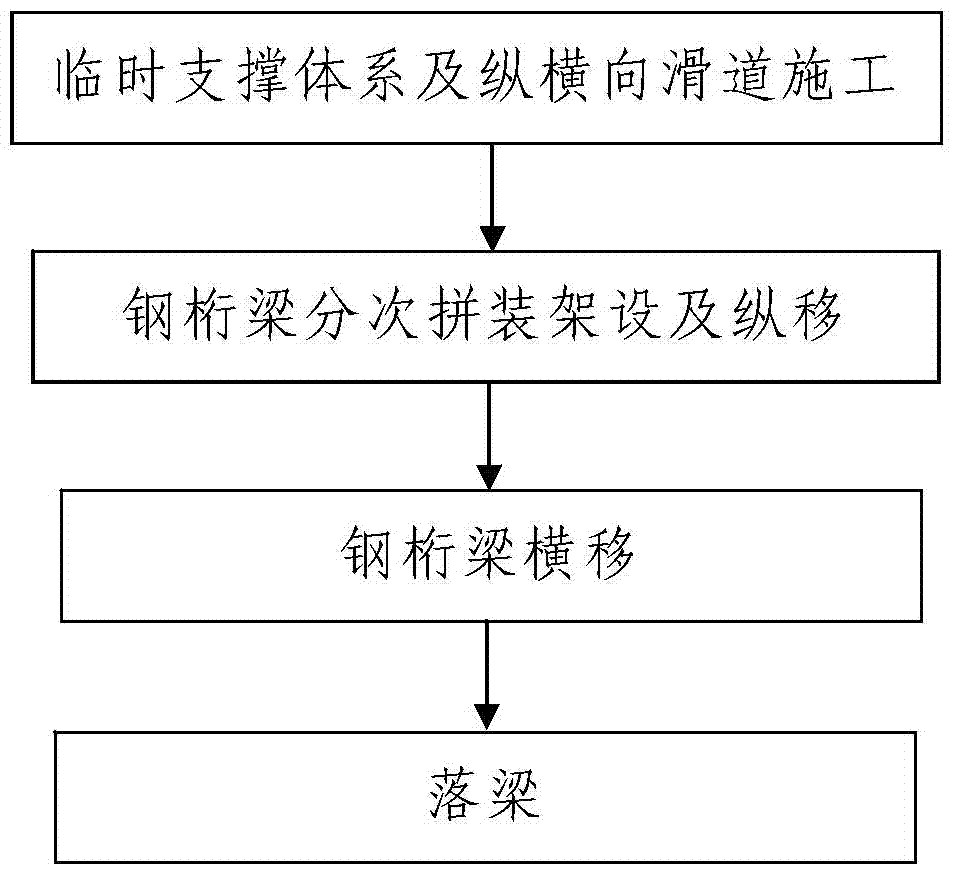

Steel truss girder assembling, erecting and construction process

A construction technique and technology of steel truss girder, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of difficult foundation design and construction of temporary buttresses, rapid water flow, and large changes in river bed scouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

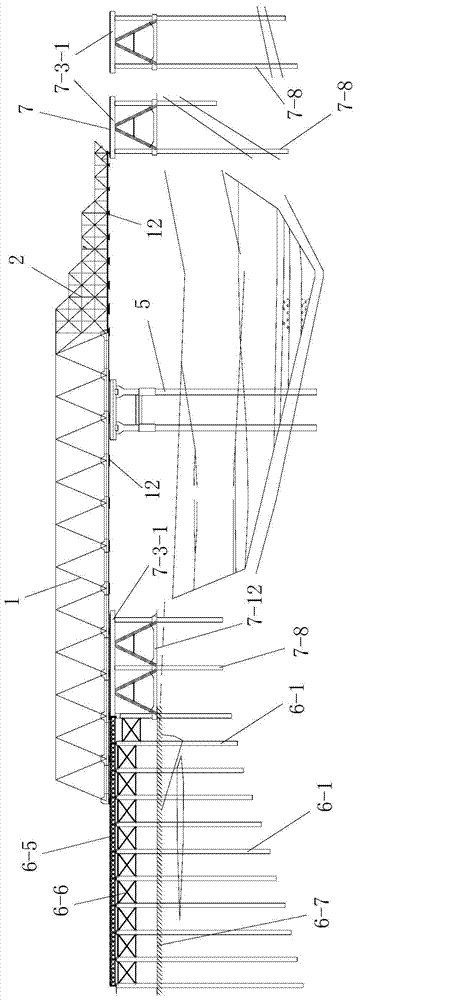

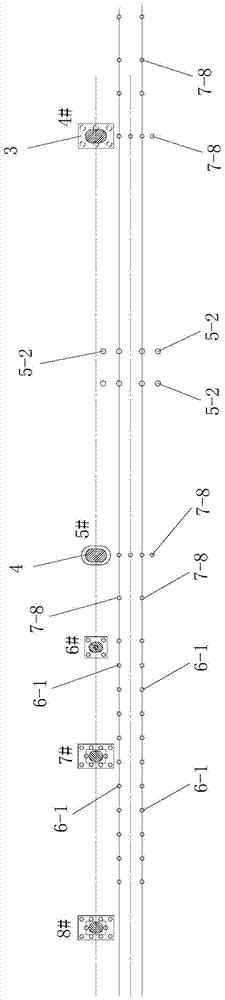

[0081] like figure 1 , figure 2 and image 3 As shown, in the construction process of a steel truss girder assembly erection described in the present invention, the erected steel truss girder 1 is a beam body whose front and rear ends are respectively supported on the permanent pier 1 3 and the permanent pier 2 4, and it consists of multiple A steel truss beam segment is assembled from front to back, and the permanent buttress 3 and the permanent buttress 2 4 are respectively located on both sides of the main channel of the river; the permanent buttress 3 and the permanent buttress 2 4 are all laid on On the straight line l1; the front part of the steel truss 1 is provided with a guide beam 2, and the guide beam 2 is arranged in front of the steel truss 1; the construction process of the assembled erection of the steel truss 1 is as follows:

[0082] Step 1. Temporary support system and vertical and horizontal slideway construction: construct a temporary support system on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com