Railway T-beam erecting construction method based on continuous beam laying reloading points

A construction method and railway technology, applied in the direction of bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of many construction equipment and construction personnel, slowing down of beam erection progress, and large construction cost, so as to achieve flexible use methods and reverse engineering. The effect of fast installation and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

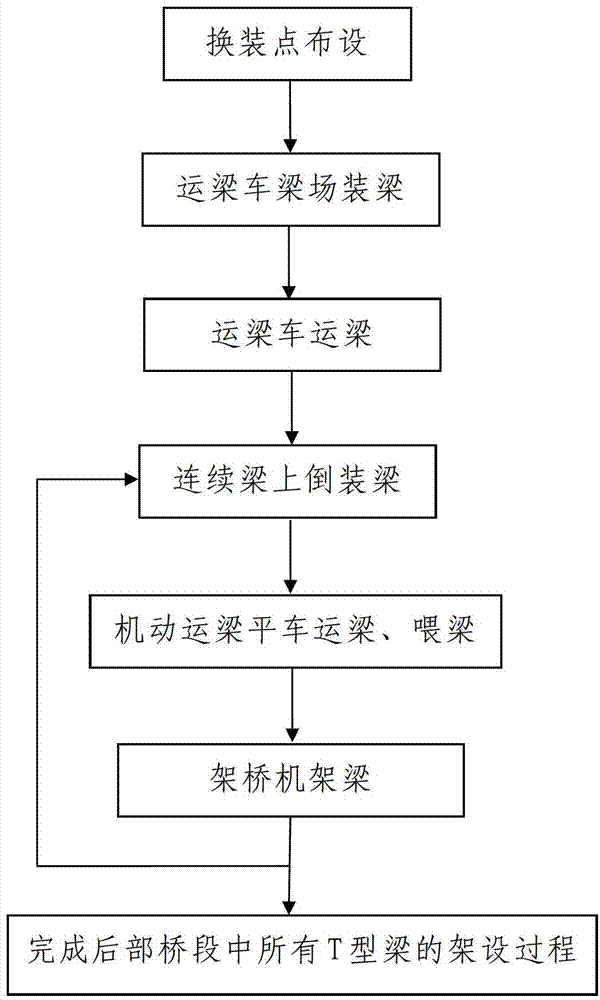

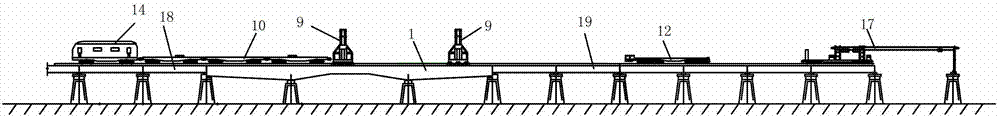

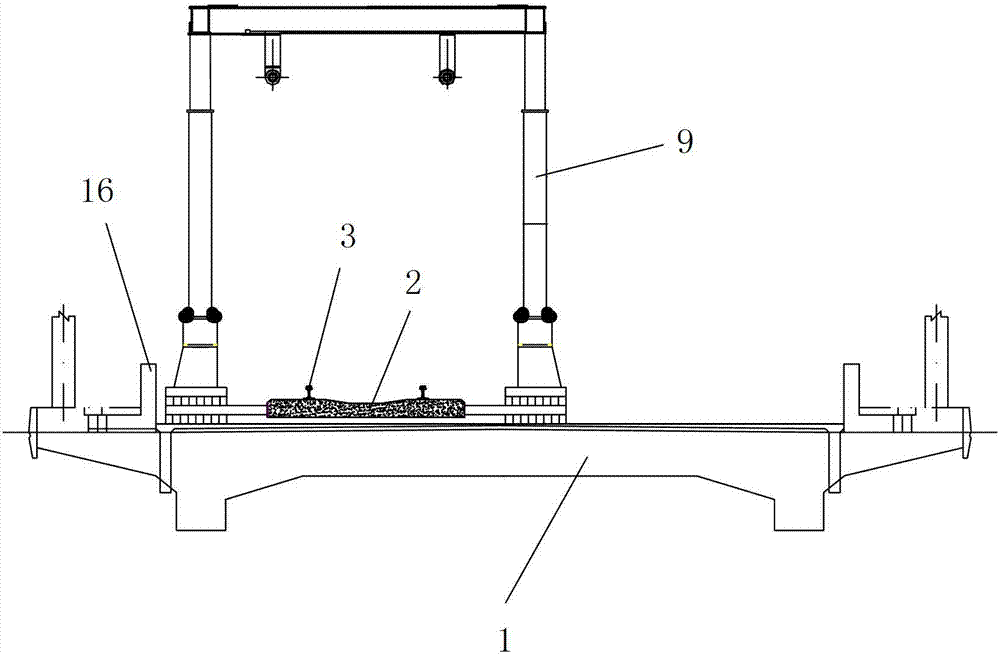

[0054] like figure 1 Shown is a railway T-beam frame construction method based on continuous beam layout and replacement points. The bridge to be constructed is a railway bridge with a bridge length greater than 2km and a railway track laid on it. The bridge to be constructed includes the completed front The first bridge section 18, the unfinished rear bridge section 19 behind the front bridge section 18, and the middle bridge section 1 connected between the front bridge section 18 and the rear bridge section 19 and completed, the The middle bridge section 1 is a continuous beam, and the rear bridge section 19 is composed of multiple T-beams assembled. The bridge structure constructed is detailed in figure 2 .

[0055] In this embodiment, the railway track includes two steel rails 3 arranged along the bridge direction, and the two steel rails 3 are paved on the concrete sleeper 2, and a layer of stone ballast leveling layer 4 is installed on the bottom of the concrete sleepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com