Tensioning method for prestressing tendons adjacent to existing line box girders

A technology of prestressed beams and existing lines, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of increasing construction difficulty for workers, increasing construction costs, and limiting safety distances, so as to shorten the construction period, reduce construction difficulty, The effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

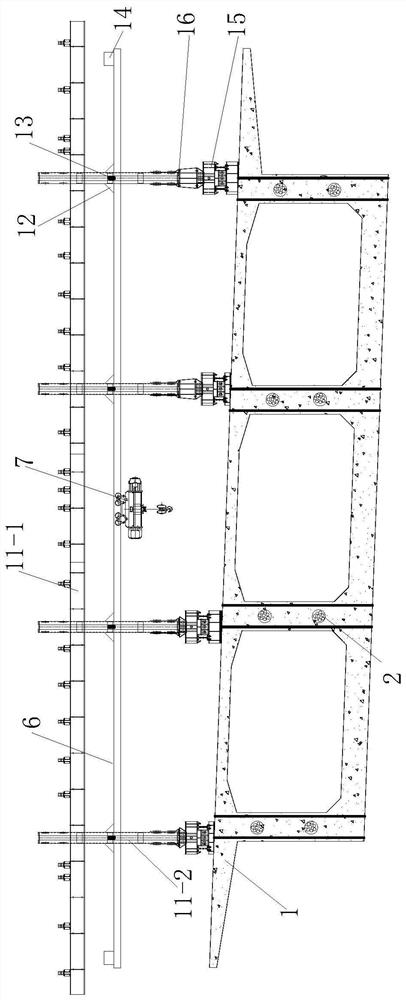

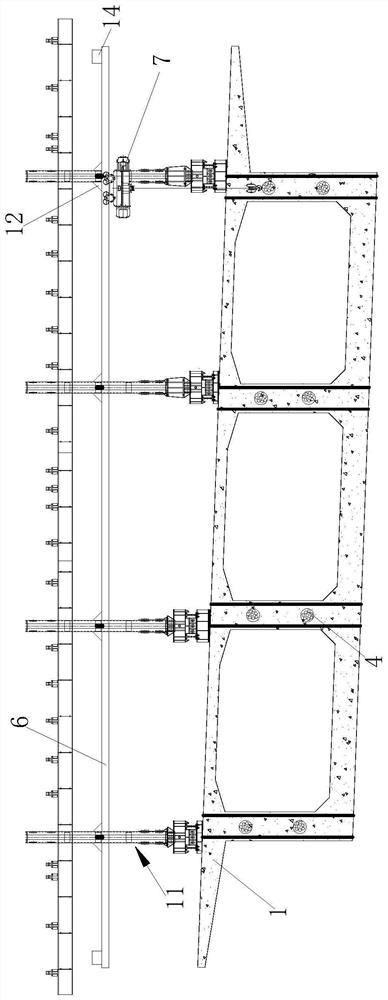

[0043] Such as Figure 1 to Figure 6Shown, a kind of adjacent existing line box girder prestressed bundle stretching method of the present invention comprises the following steps:

[0044] Step 1. Install the tensioning lifting device: install the tensioning lifting device on the main truss 11 of the hanging basket. The beam 11-1, the main body of the truss and the beam 11-1 are integrally formed;

[0045] The main girder 6 is welded on the truss main body, and the main girder 6 is horizontally arranged below the beam 11-1. The length of the main girder 6 is greater than the width of the truss main body, and the truss main body and the The main girder 6 is fixedly connected by a connecting assembly; the main girder 6 is hung with a hoist 7, and the hoist 7 can move along the length direction of the main girder 6; the truss main body, the main girder 6 and the hoist 7 form a sheet pull the hoist;

[0046] Step 2, pouring and maintaining the box girder: a hanging basket runni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com