An anti-dumping mechanical device and method for an inner suspension stay wire holding rod

A mechanical device and anti-dumping technology, applied in the direction of towers, building types, buildings, etc., to prevent accidents, ensure absolute safety, and avoid repeated installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

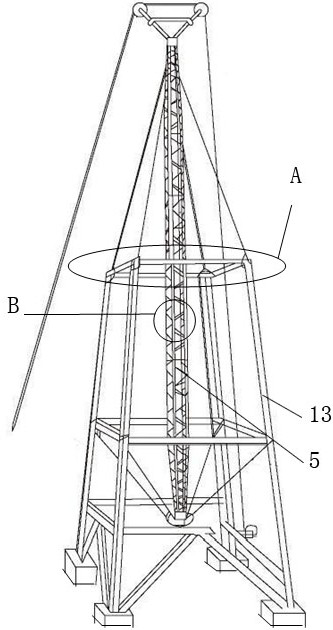

[0042] Such as figure 1 As shown in FIG. 1 , an anti-dumping mechanical device with an inner suspension stay wire holding rod includes a trigger mechanism and an anti-dumping mechanism.

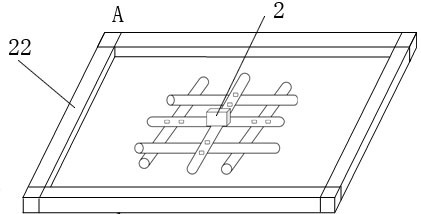

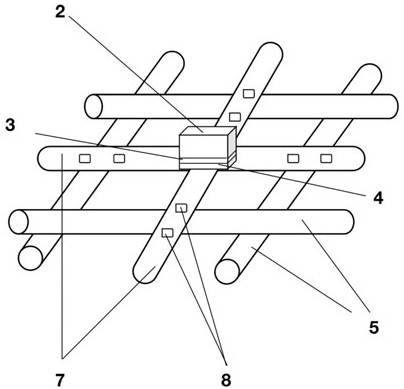

[0043] Such as Figure 2-7 As shown, the trigger mechanism includes a trigger box 2, the bottom of the trigger box 2 is fixed with the magnetic upper layer 3 by welding, the magnetic upper layer 3 is magnetically fixed with the magnetic lower layer 4, and the magnetic lower layer 4 is welded with the connecting plate 7 fixed. There are 2 connecting plates 7 in a cross-shaped distribution. The connecting plate 7 is processed from an aluminum plate, and an aluminum plate with high hardness and not easy to break is selected for use. There are four pole fixing holes 8 on both sides of each connecting plate 7 , and the U-shaped ring 11 passes through the pole fixing holes 8 of the aluminum plate 7 and is fixed with the pole 5 . The bolt 9 and the nut 10 pass through the U-shaped ring connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com