Multi-knife lathe tool clamp

A turning tool and blade technology, applied in the field of multi-tool turning tool holder, can solve the problems of low production efficiency, inability to meet production technical requirements, uneconomical processing technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

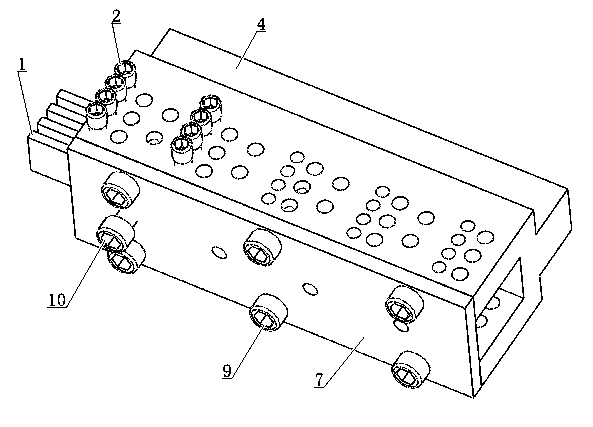

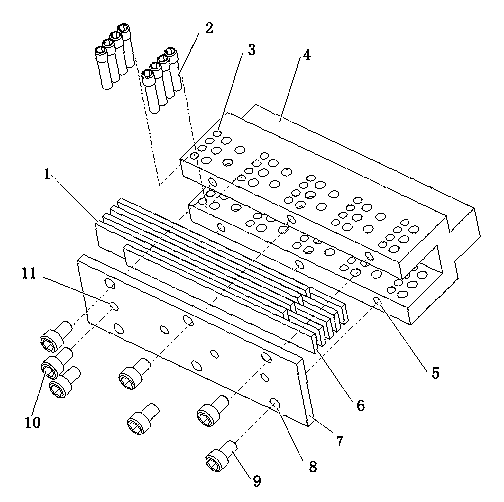

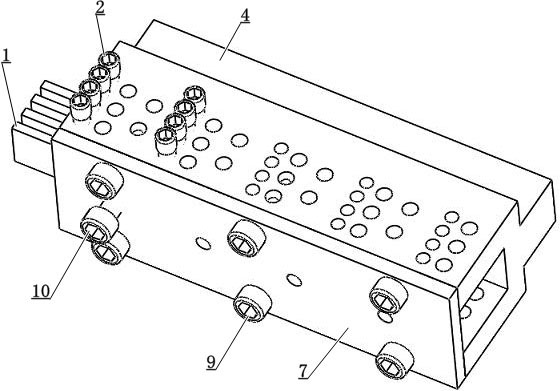

[0011] Such as figure 2 As shown, the multi-tool turning tool holder includes a turning blade 1, a compression bolt 2, a turning tool clamp body 4, a backing blade 6, a side pressure plate 7, a screw 9, and a side pressure bolt 10, and is characterized in that the side pressure plate 7 passes through the hole 8. The threaded hole 5 is installed on the side of the turning tool clamp body 4 with a screw 9, the turning blade 1 and the backing blade 6 are placed in the long groove of the turning tool clamp body 4, and the side pressure bolt 10 passes through the threaded hole of the side pressure plate 7 11 After the side pressure pre-tightening of the turning blade 1, use the compression bolt 2 to compress the turning blade 1, and then lock the side pressure bolt 2.

[0012] In the multi-tool turning tool holder of the present invention, multiple rows of threaded holes 3 are provided on the upper and lower surfaces of the turning tool holder body 4 .

[0013] The upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com