Lifting type spiral turning drill hole turning machine

A technology of auger drilling and auger drilling rigs, which is applied in the field of compost turners, can solve the problems of inconvenient turning interval, adjustment of turning frequency and cross-groove operation, poor adaptability of composting and continuous composting, and high failure rate. Large-scale continuous composting automatic turning operation, convenient large-scale continuous composting automatic turning operation, and the effect of reducing operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

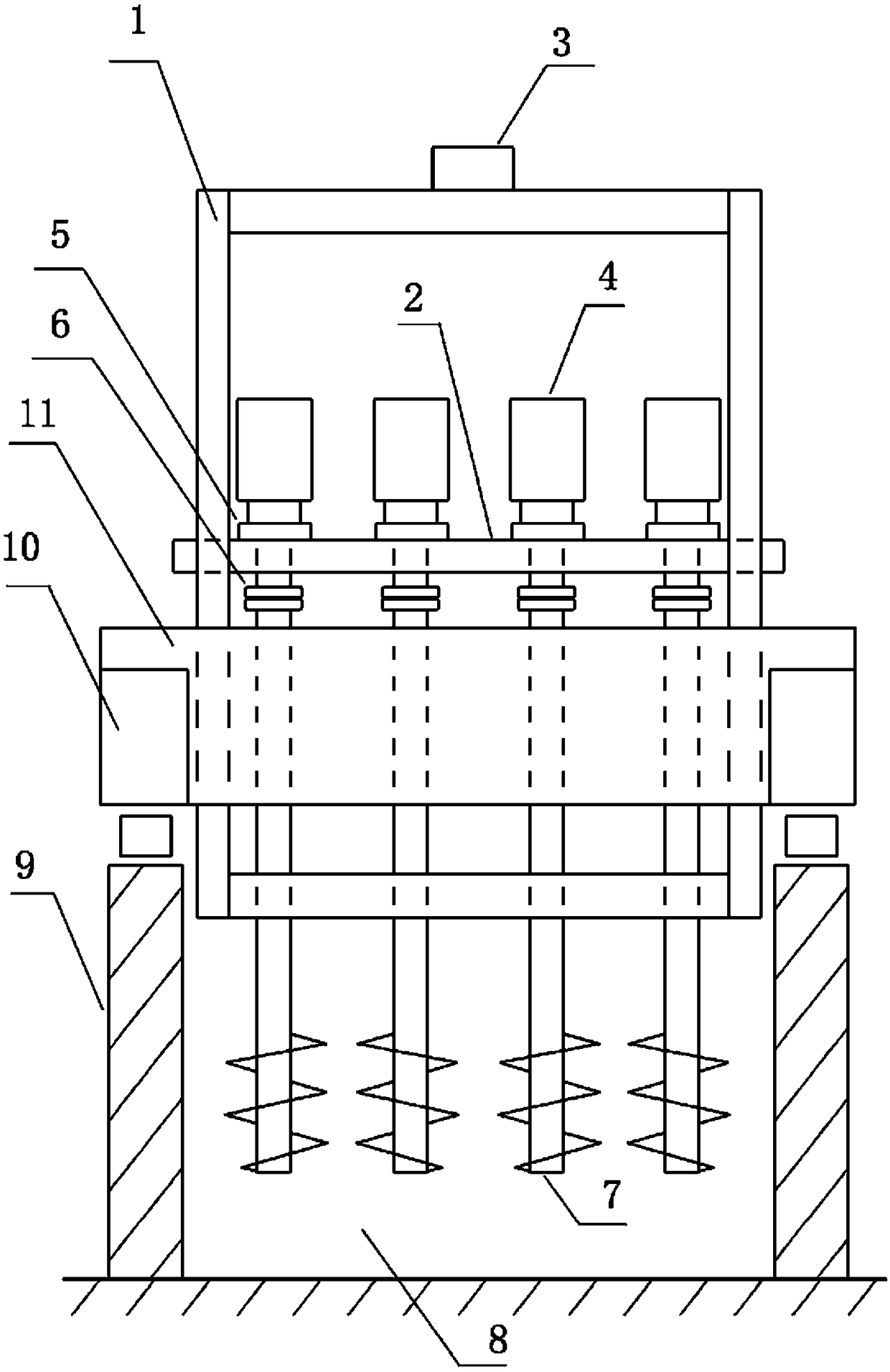

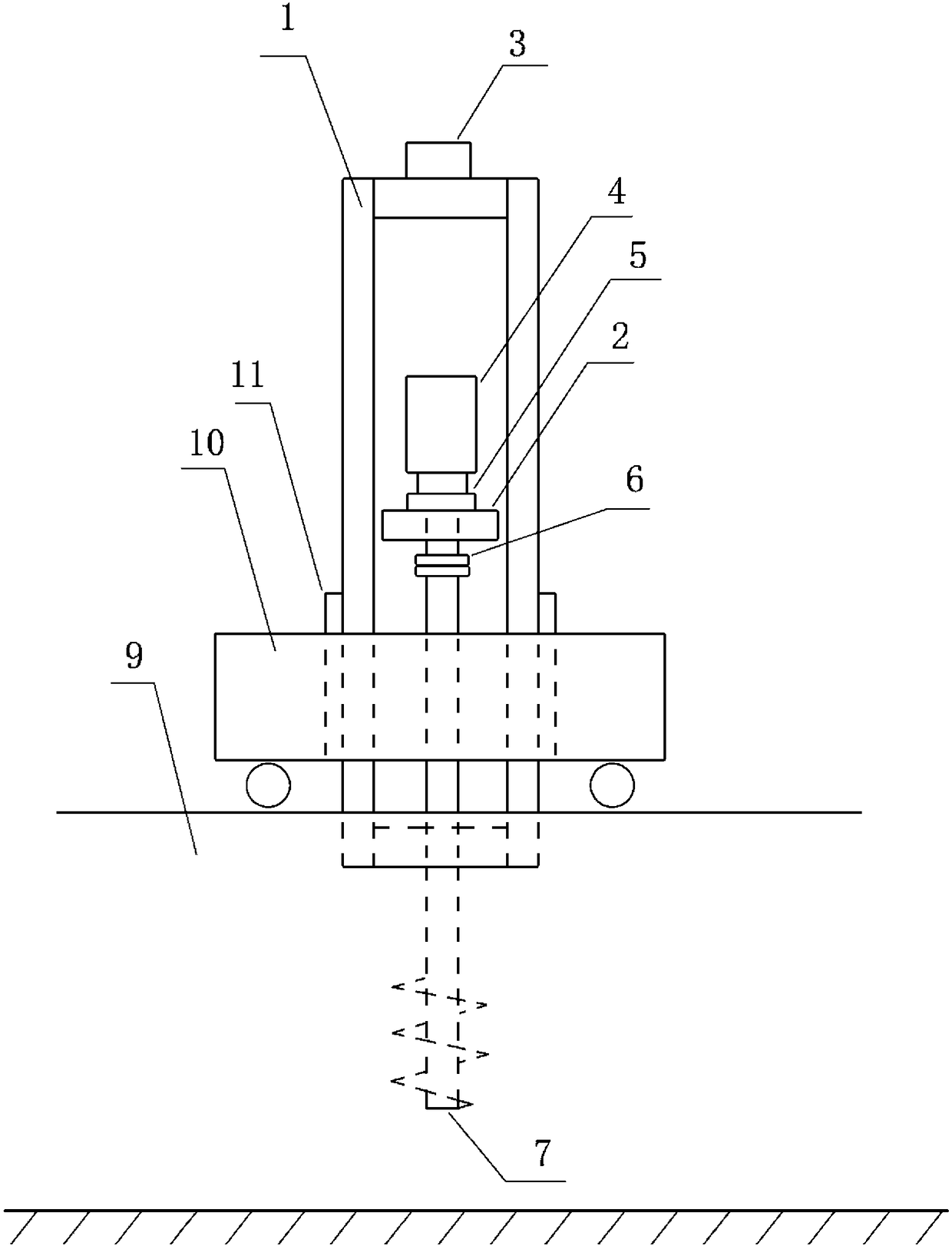

[0011] Embodiment one, such as figure 1 As shown, the rail-type mobile beam frame of the present invention spans a single fermenter, and an elevating auger is installed. The end beam 10 of the mobile beam frame is located on the wall 9 of the fermentation tank, the auger drill is fixed between the two steel plates of the main beam 11 of the mobile beam frame through the guide rail frame 1, the drilling tool is installed on the lifting platform 2, and the electric hoist 3 is installed on the guide rail Rack 1. In the non-operating state, the lifting platform 2 stops at the highest position, and the auger bit 7 is located on the compost material. When turning over, move the beam frame along the longitudinal direction of the fermentation tank 8, and move the auger drill to the position where drilling and turning over are required; the moving beam frame stops, and the auger drill starts lifting, drilling and turning over; the electric hoist 3 lowers the lifting platform 2 At the...

Embodiment 2

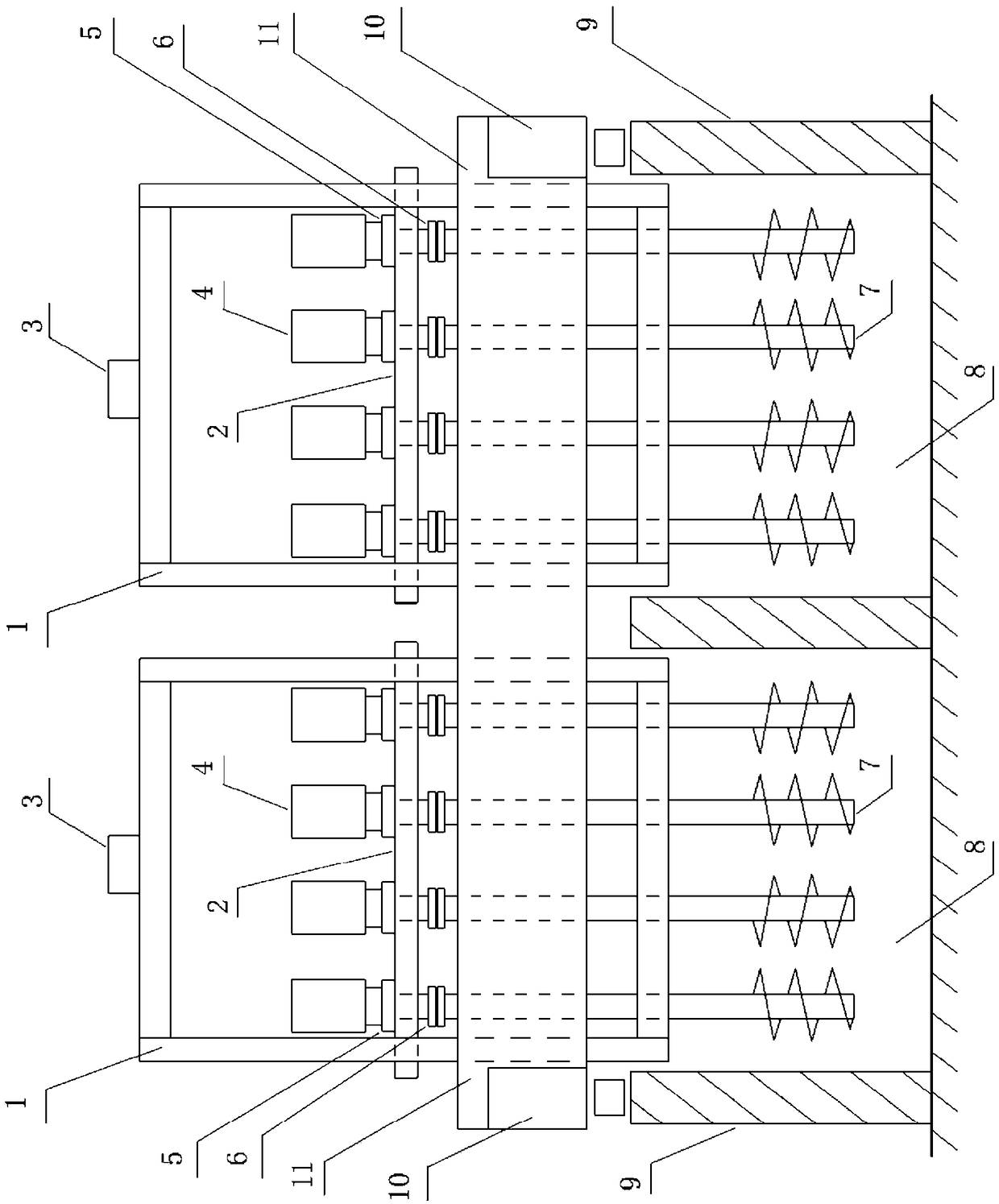

[0012] Embodiment two, such as image 3 As shown, the rail-type mobile beam frame of the present invention spans two fermentation tanks, and two lifting auger machines are installed. The end beams 10 of the mobile beam frame are located on the outermost walls of the two fermentation tanks, and the main beam 11 of the mobile beam frame spans the two fermentation tanks. An elevating screw drilling rig is respectively installed on the main girder 11 of the mobile beam frame corresponding to each fermenter. In the non-operating state, the lifting platform 2 stops at the highest position, and the auger bit 7 is located on the compost material. When turning over, the beam frame is moved longitudinally along the fermentation tank 8, and the lifting auger drill is moved to the position where drilling and turning is required; the moving beam frame stops, and the auger machine starts lifting, drilling and turning over; the electric hoist 3 is lowered and lifted Platform 2, while the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com