Overhead green brick turnover equipment used for hollow brick production

A hollow brick and blank-turning technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of high brick damage rate, low blank-turning efficiency, and large footprint, and achieves low maintenance cost, high efficiency and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

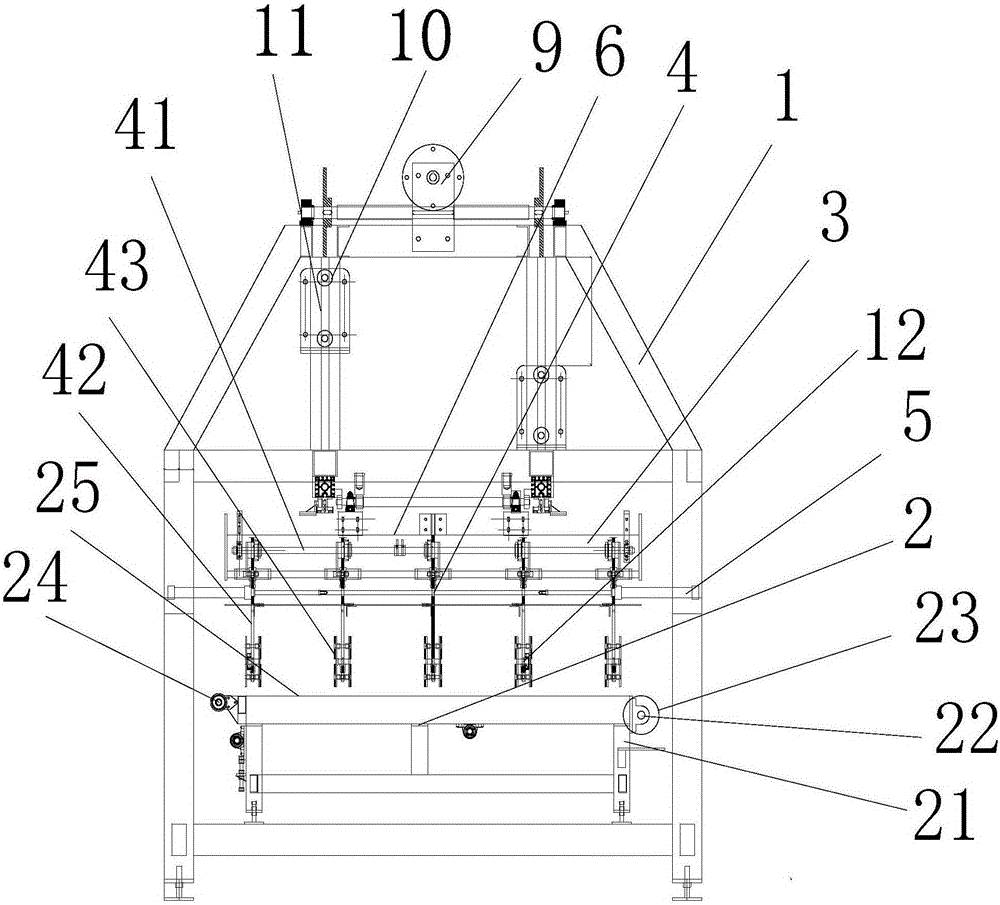

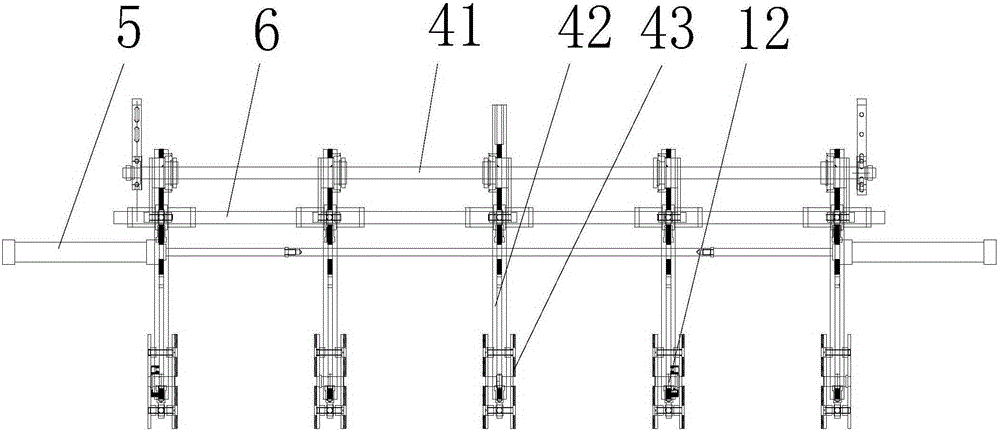

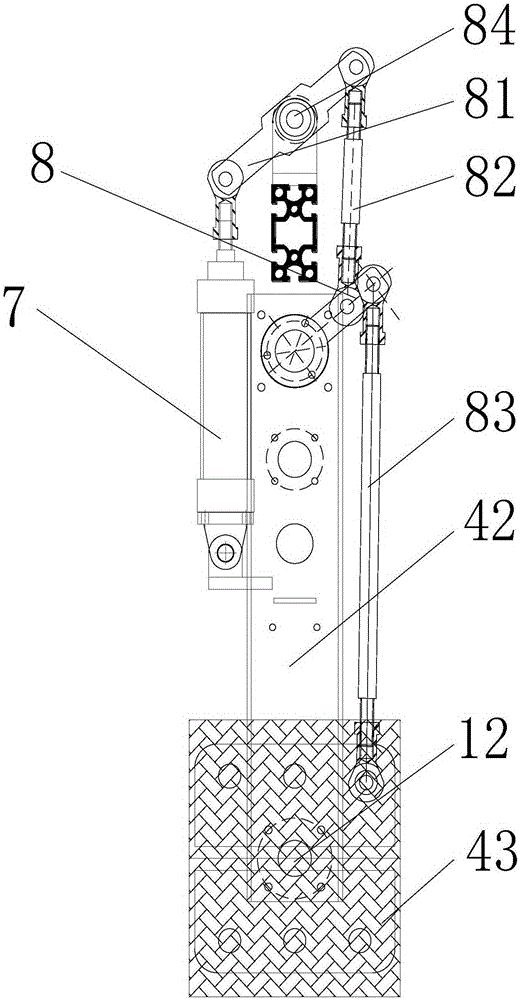

[0028] Such as figure 1As shown, a suspended blank turning equipment for the production of hollow bricks includes a support 1, a transmission device 2 and a suspended turning mechanism that rotates the hollow brick adobe vertically by 90° in the air; the transmission device 2 is installed on the support 1 directly below; the overturning mechanism is installed on the support 1; the transmission device 2 and the overturning mechanism work together through PLC and servo mechanism control. The suspended turning mechanism includes a support frame 3 movably installed on the bracket 1, six clamps 4 mounted on the support frame 3 for clamping the hollow brick adobe in the air, and control clamps 4 installed on the support frame 3 to move closer / closer to each other. A separate first control mechanism, a second control mechanism installed on the support frame 3 to control the rotation of the clamp 4 and a third control mechanism installed on the support 1 to control the vertical moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com