Patents

Literature

49results about How to "Save site resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

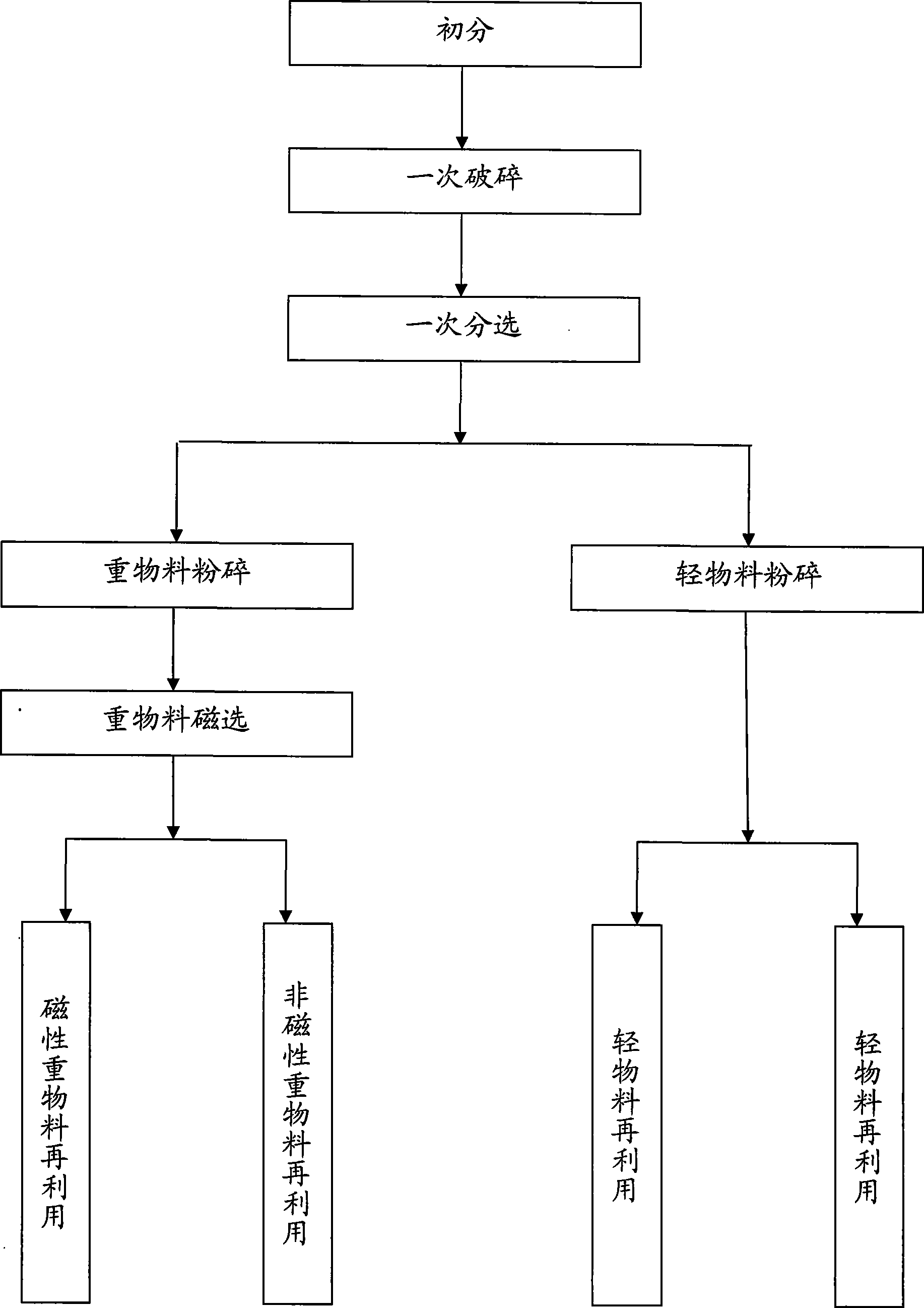

Specification process method for urban pollutant

InactiveCN101244423ARealize resourcesSave site resourcesSolid waste disposalSolid separationResource utilizationEngineering

Owner:BEIJING HENGYECUN S&T

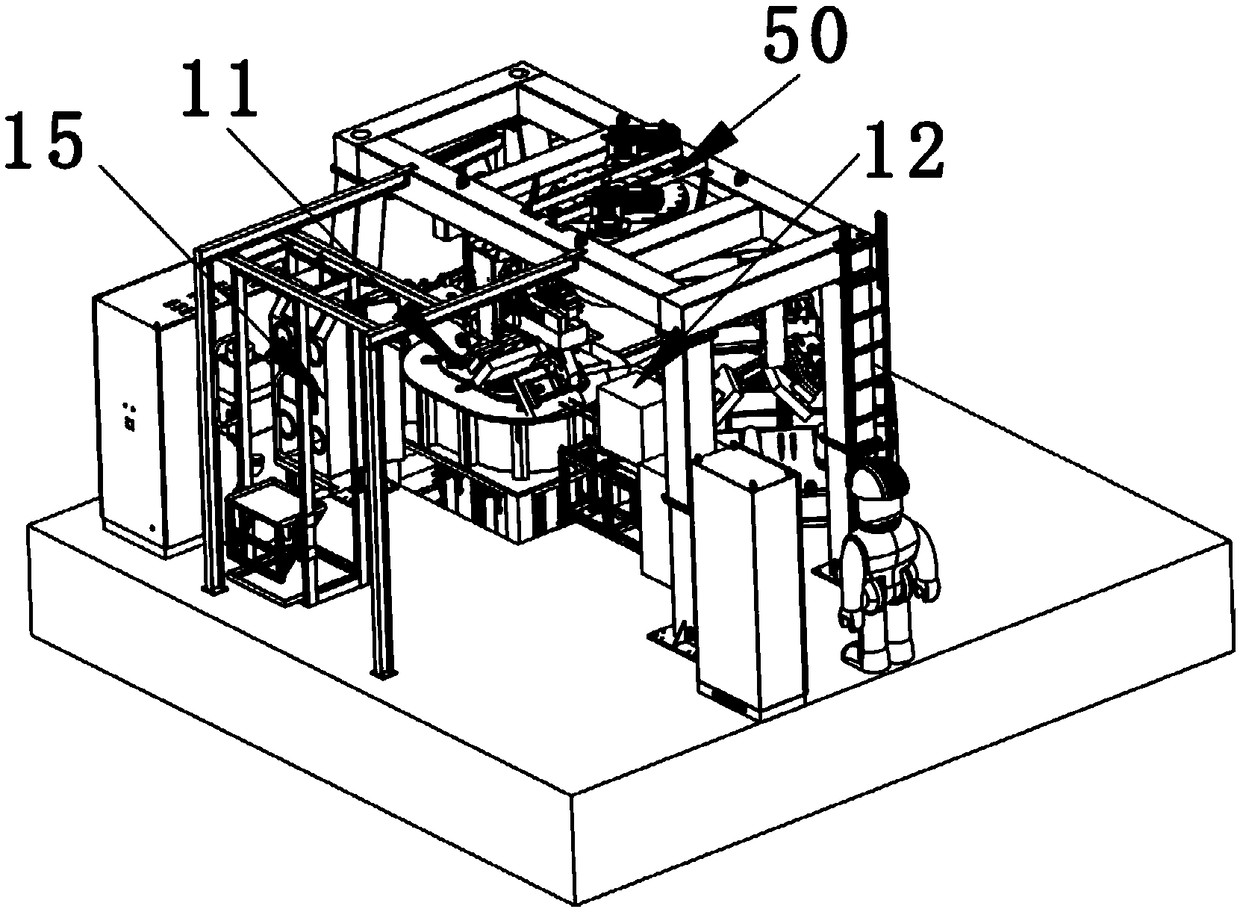

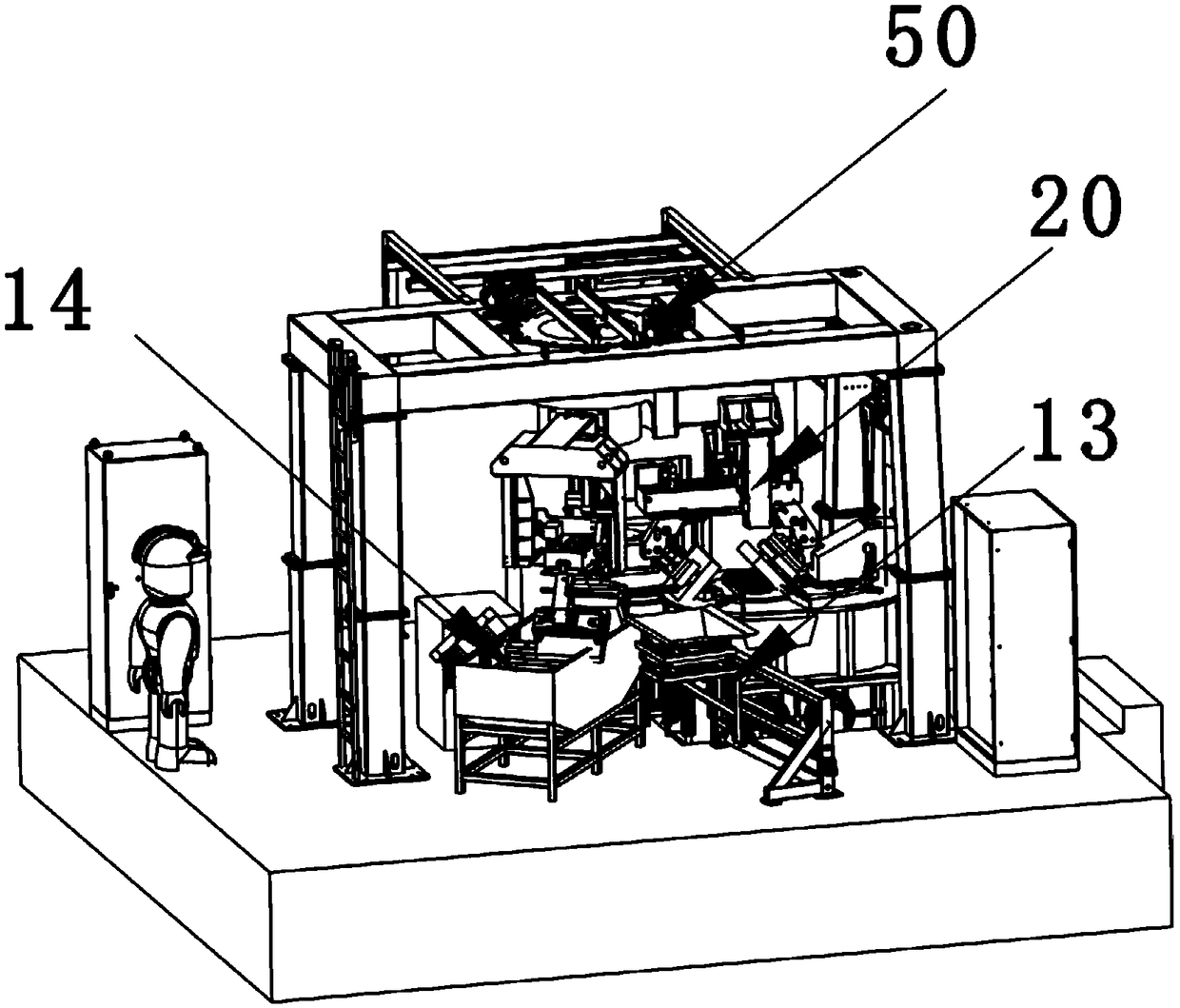

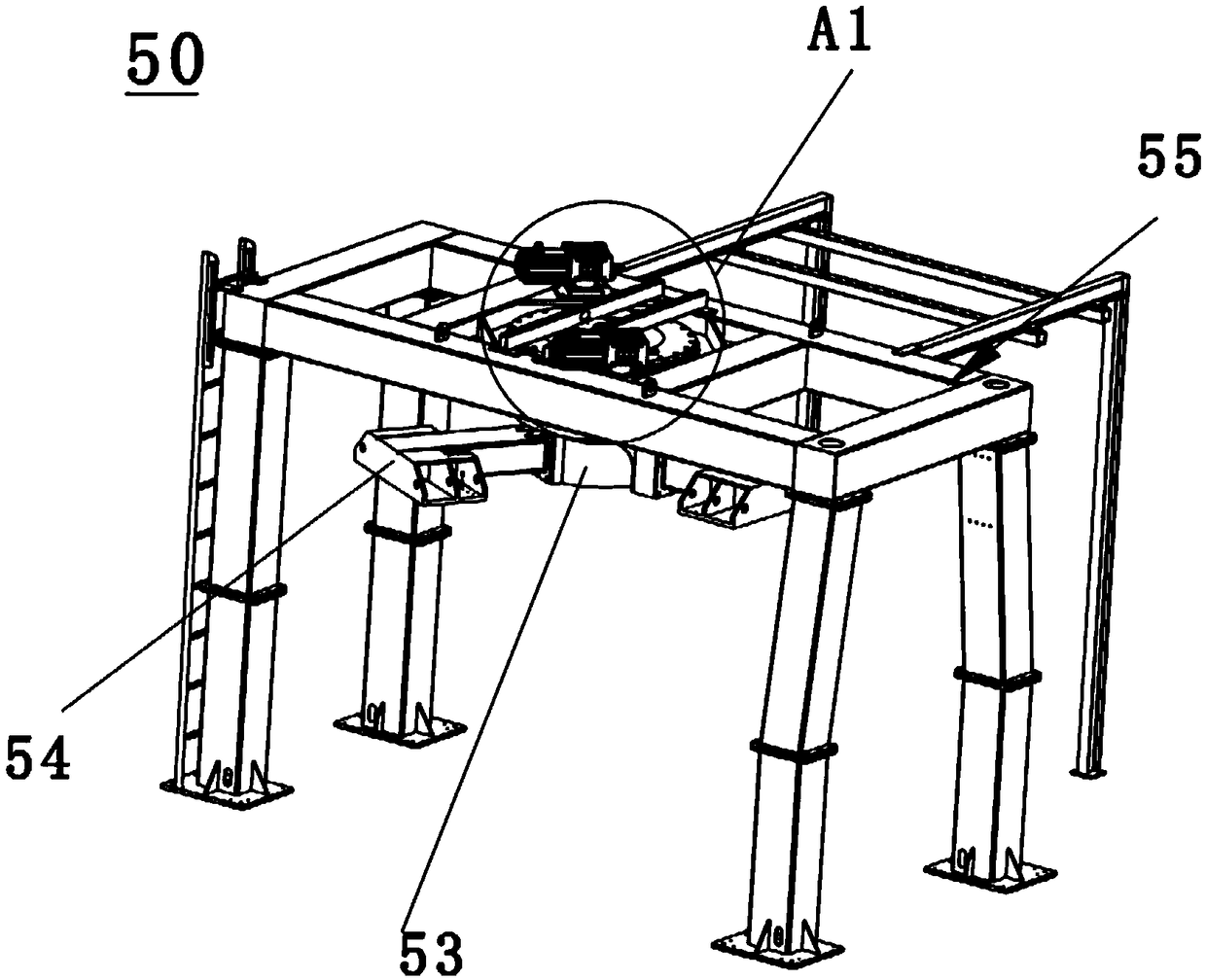

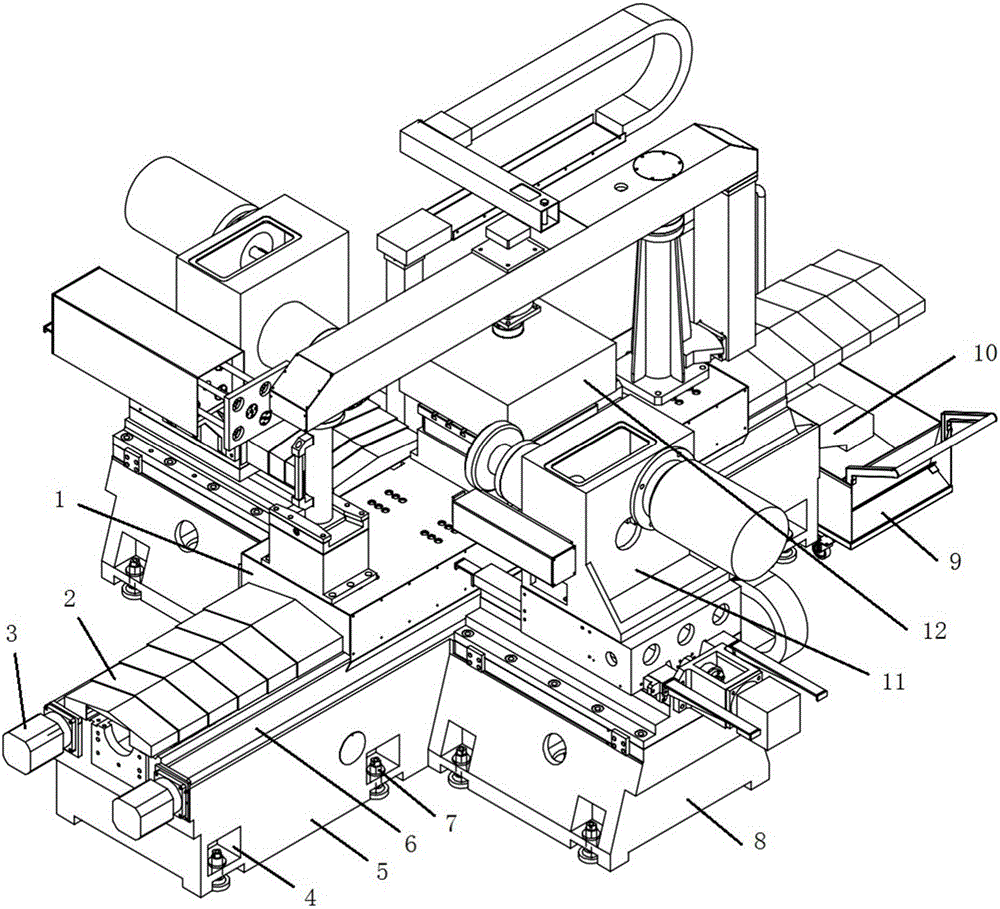

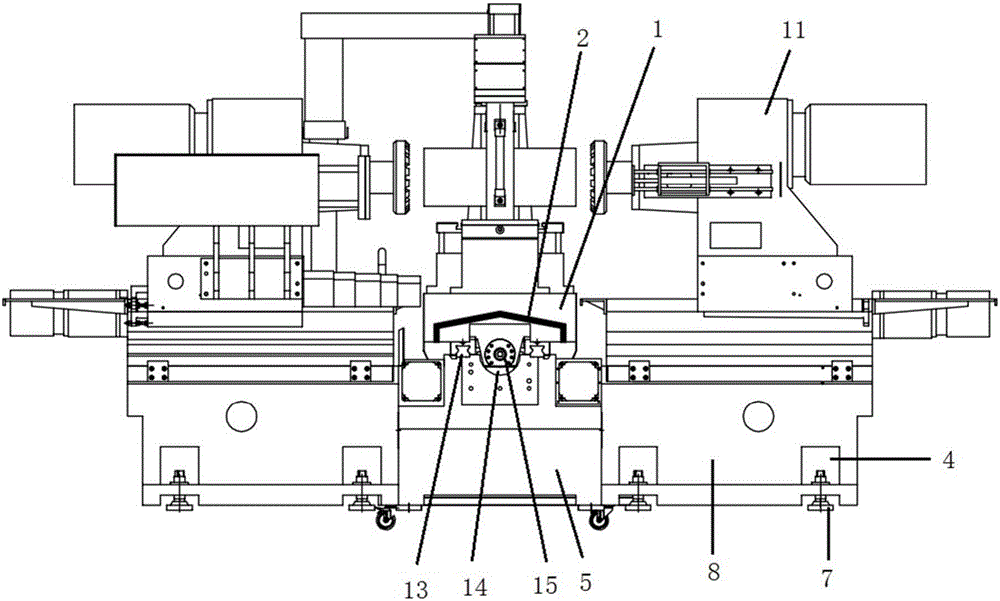

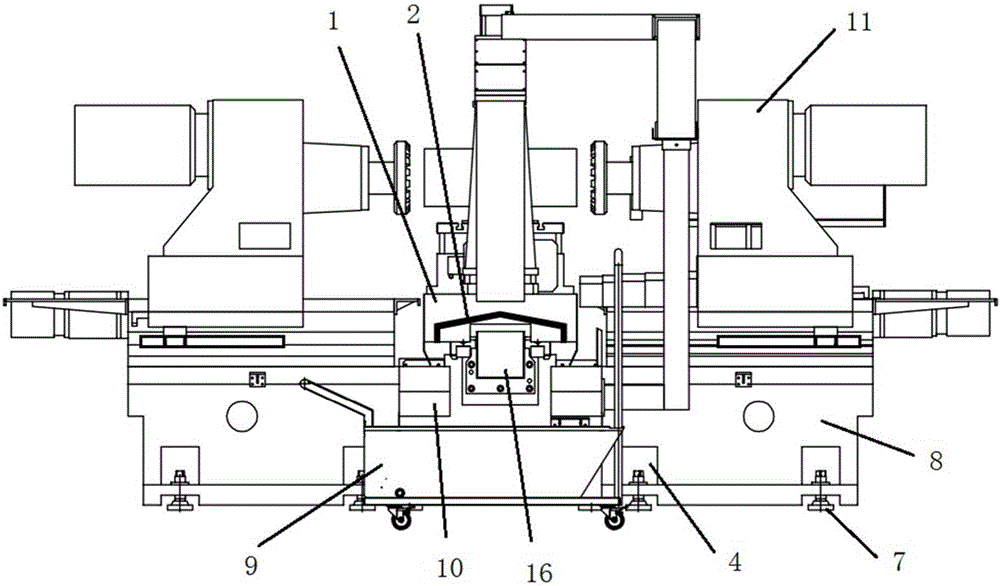

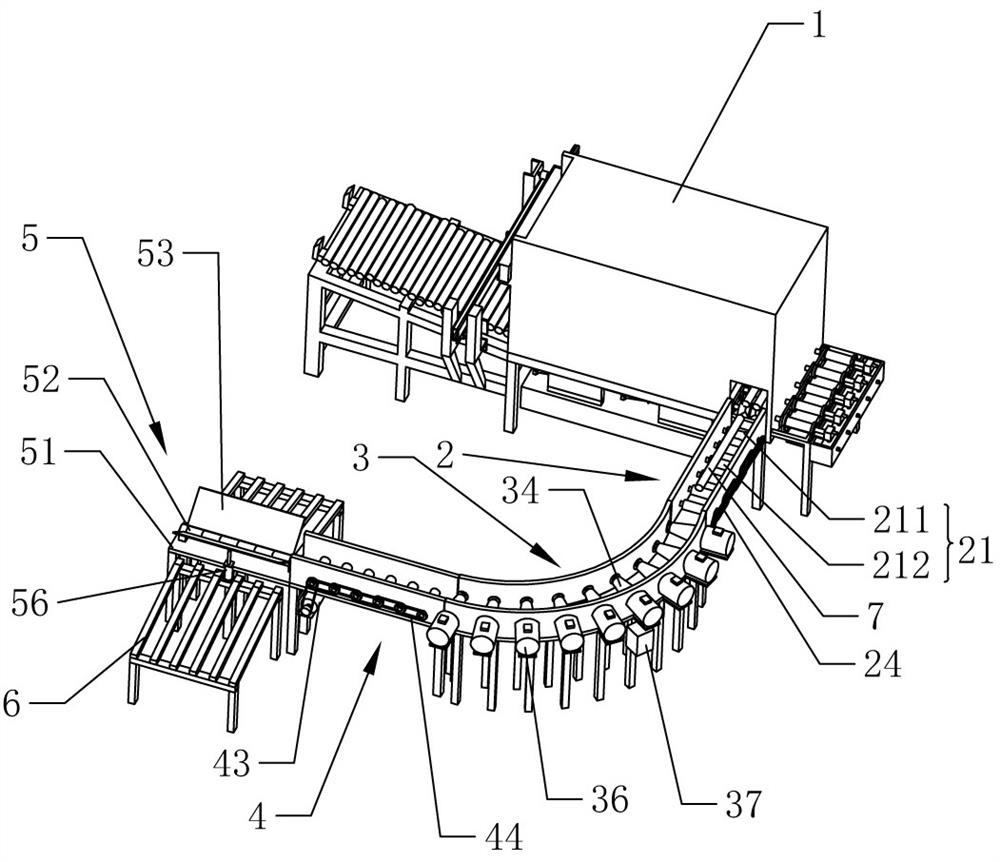

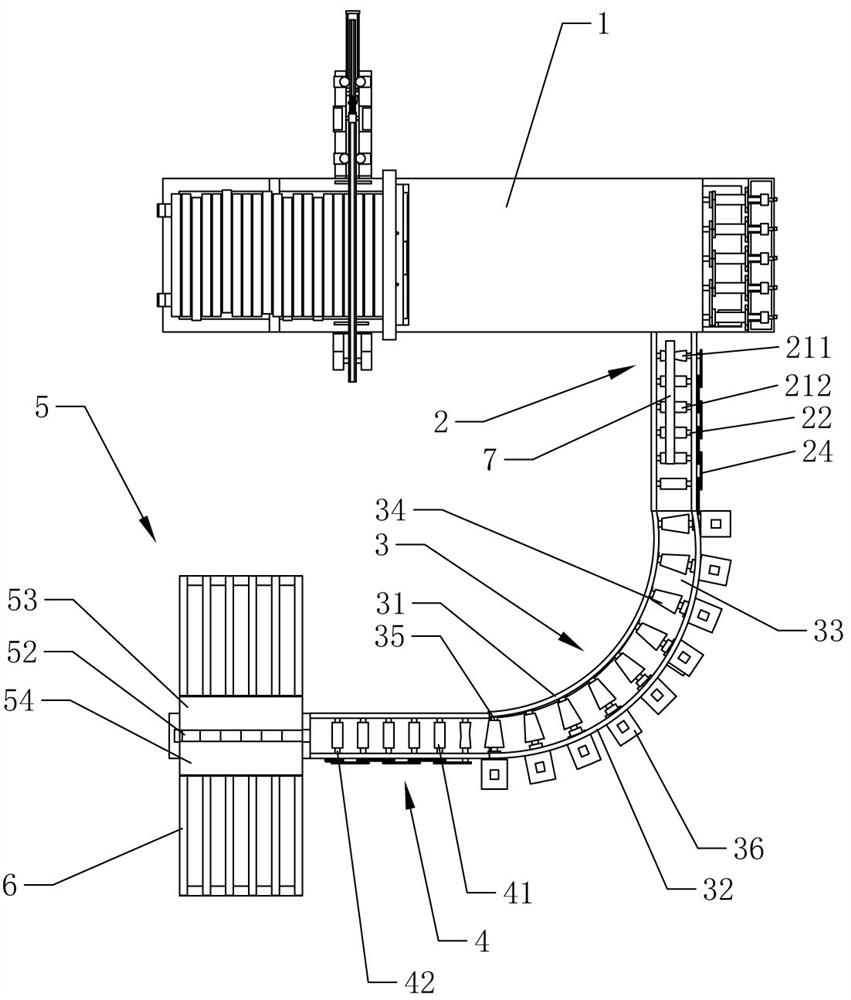

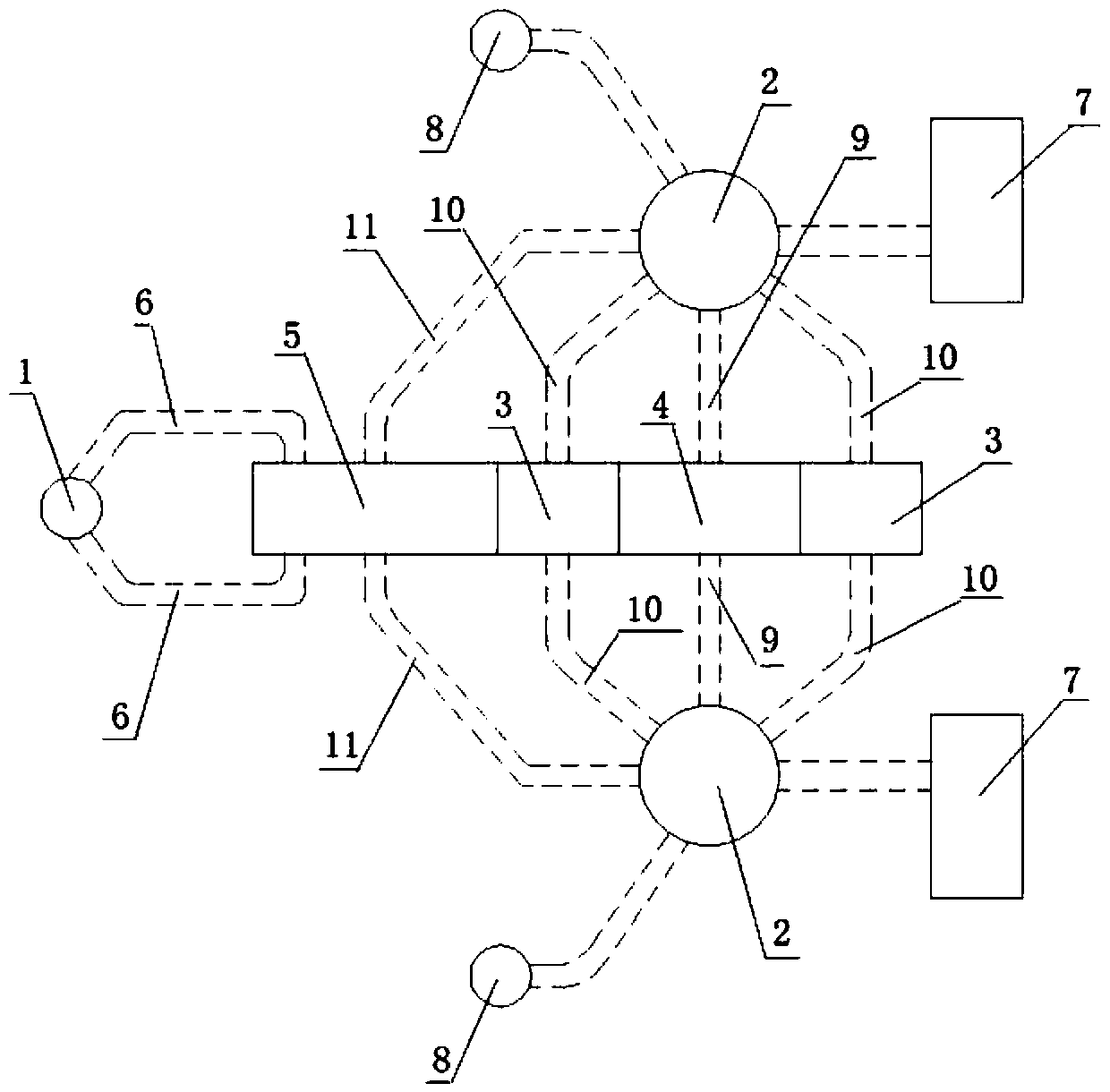

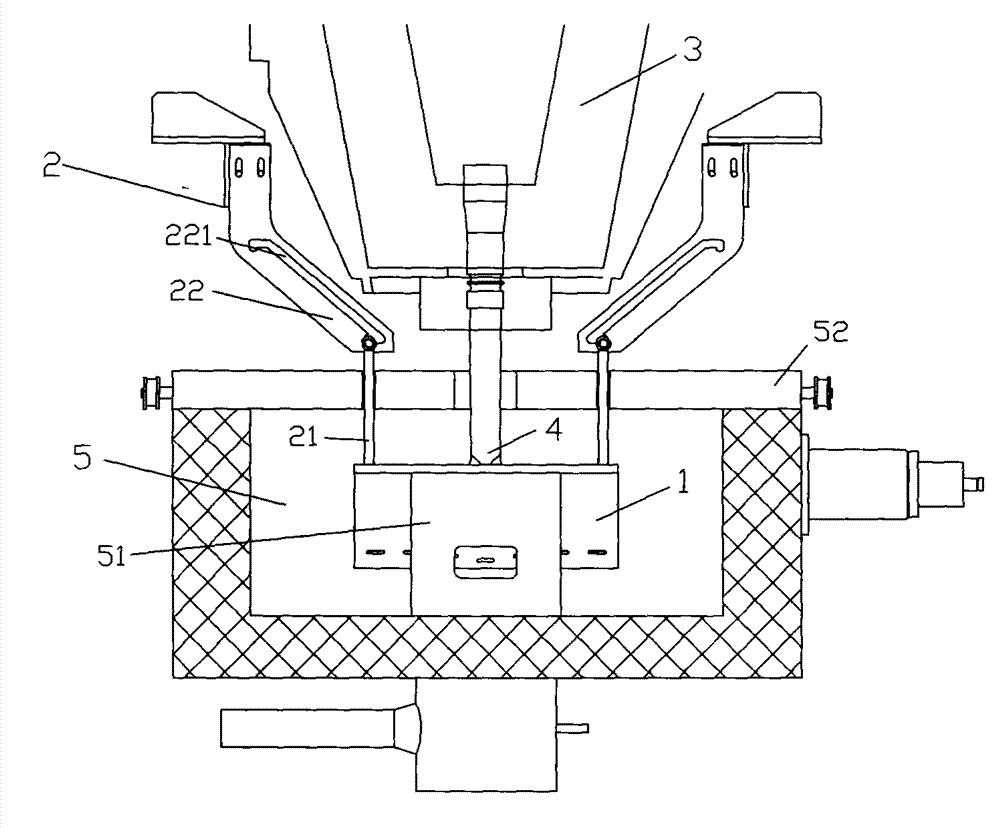

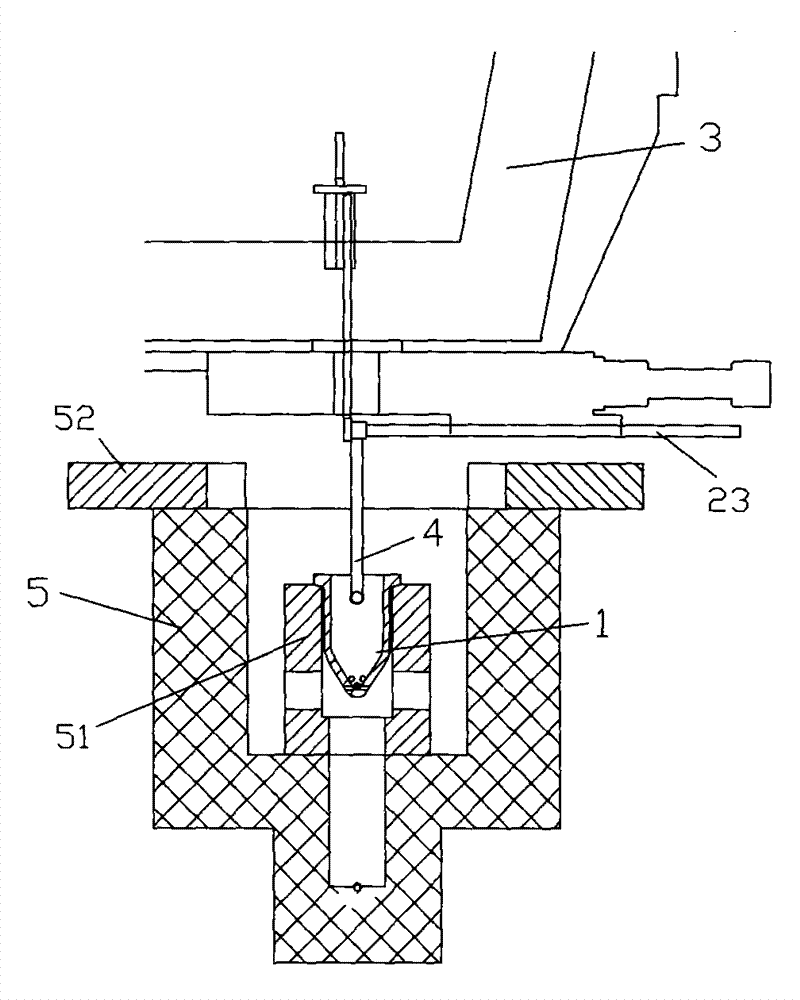

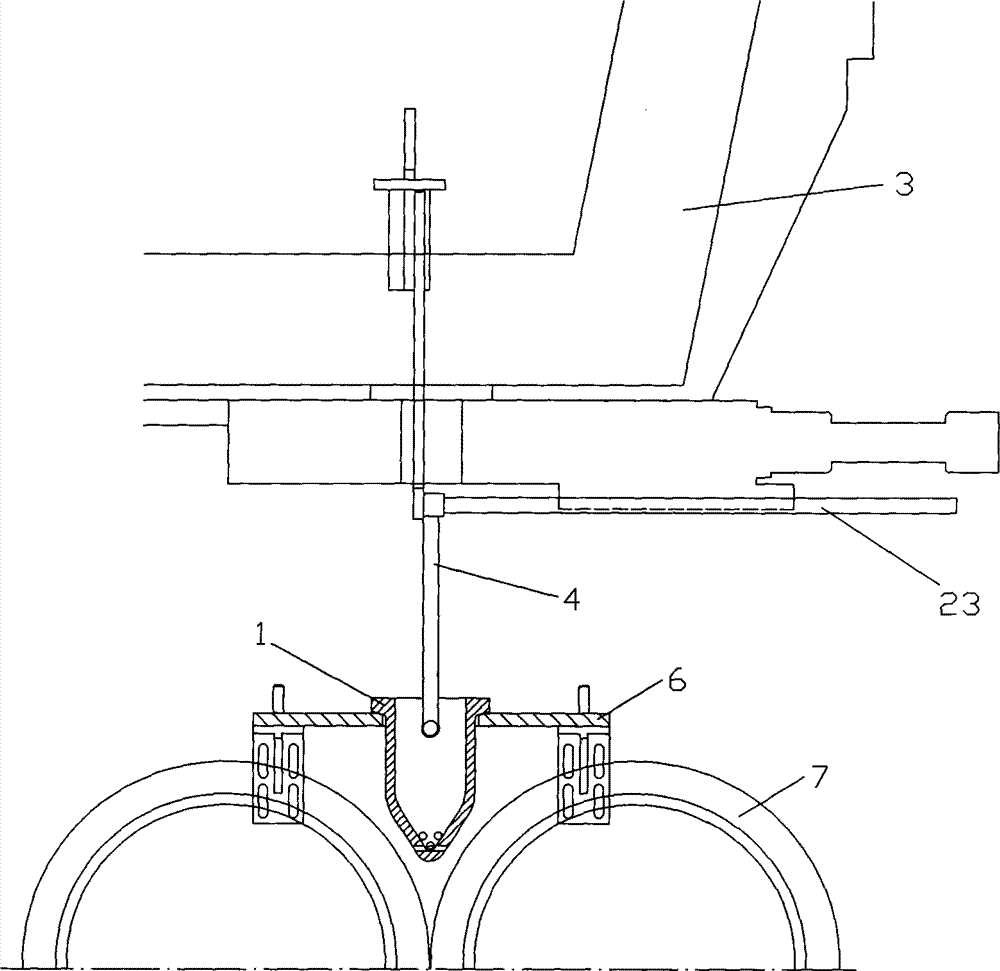

Efficient multi-station casting machine and casting method thereof

The invention provides an efficient multi-station casting machine and a casting method thereof. The multi-station casting machine is provided with first to fourth stations correspondingly used for sand core placing, mold filling, feeding and soaking. The first to the fourth stations are arranged in an annular mode. The casting machine is further provided with a rotating mechanism, and 2-4 manipulators. The rotating mechanism can drive the manipulators to respectively pass through the first, second, third and fourth stations in a cycling mode. Each time when the rotating mechanism rotates, the2-4 manipulators respectively correspond to one of the stations. Two to four parts of castings can be produced in each production cycle. The utilization rate of a machine station is improved. The second station with largest power consumption and the longest working procedure is fully utilized thereby not being idle. An electric furnace chamber and a rise tube heater required by the second stationare high power-consuming devices. In this way, electric energy loss is reduced while efficiency is improved. Carbon dioxide emission is lowered, energy is saved, and the environment is protected.

Owner:厦门鼎铸智能设备有限公司

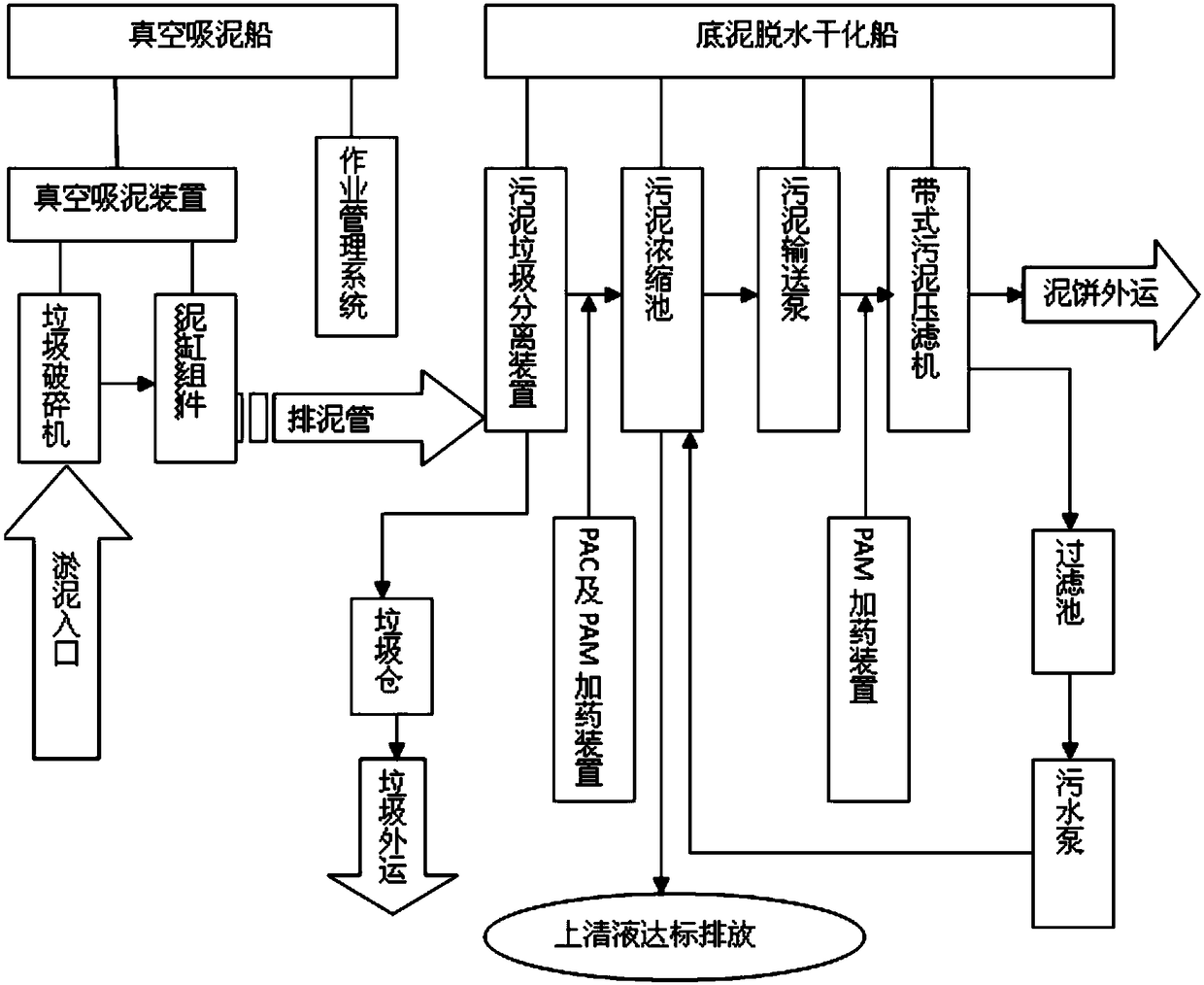

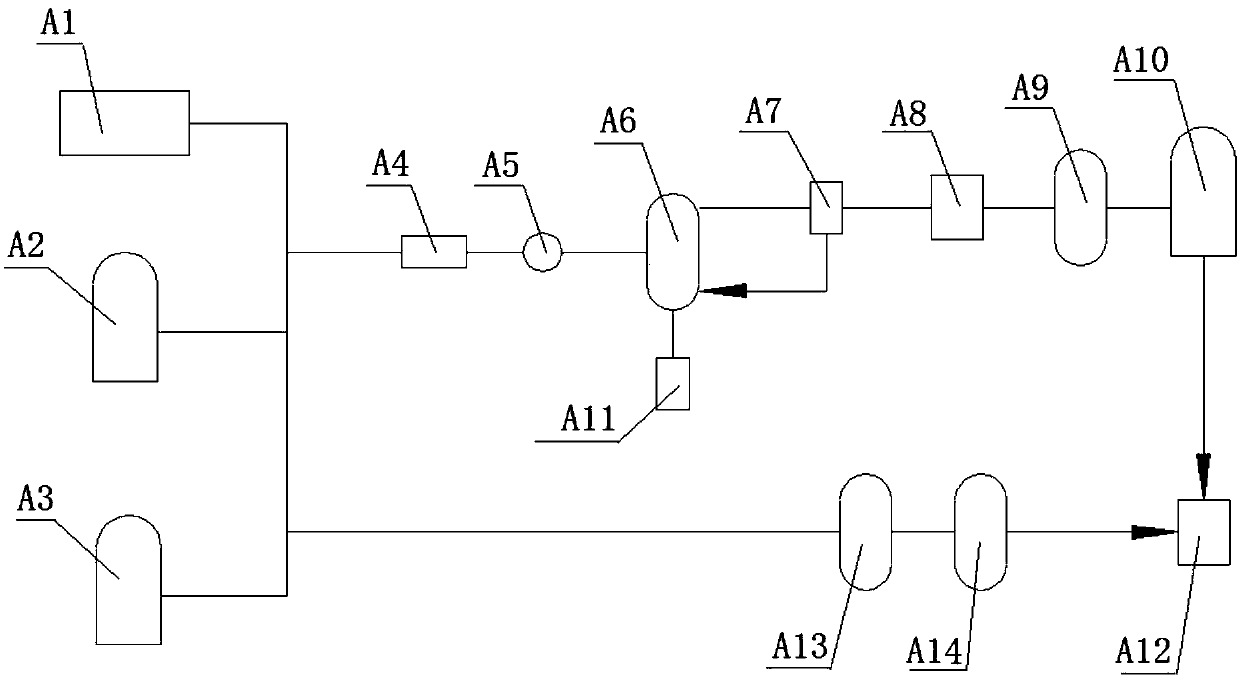

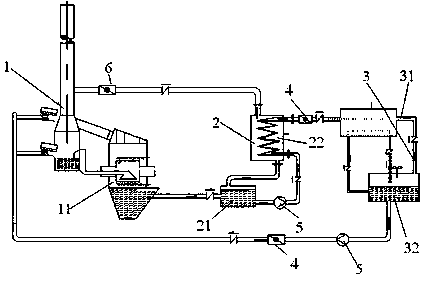

Environment-friendly system for dredging river course and treating bottom mud in on-line manner

PendingCN108341577ALow costSave site resourcesSludge treatment by de-watering/drying/thickeningMechanical machines/dredgersFlocculationSludge

The invention relates to the technical field of the dredging of river courses, and discloses an environment-friendly system for dredging a river course and treating bottom mud in an on-line manner. The environment-friendly system comprises a vacuum mud suction ship, a bottom mud dehydrating and drying ship and an operation management system, wherein the vacuum mud suction ship is provided with a vacuum mud suction device; the bottom mud dehydrating and drying ship comprises a dosing device used for accelerating the flocculation and deposition of slurry of silt as well as a sludge / garbage separating device, a sludge concentration tank, a sludge conveying pump, a belt sludge filter press and a filter tank, which are arranged according to the treatment sequence of the sludge and are further connected in sequence; a sludge outlet end of the vacuum mud suction device on the vacuum mud suction ship is connected to the sludge / garbage separating device on the bottom mud dehydrating and dryingship through a mud discharge pipe; the filter tank is connected to the sludge concentration tank through a sewage pump and a pipeline; a supernatant solution overflow pipe is arranged in the sludge concentration tank. The environment-friendly system is used for realizing the continued and streamlined on-line operation of the dredging of the river course and the treatment of the bottom mud; the dredging is free from disturbance; the slurry does not fall to the ground, and the residual water is discharged up to a standard.

Owner:南京顺如信息科技有限公司 +1

Particles showing yellow and having golden gloss

The invention relates to particles showing yellow and having golden gloss and a formula of a coloring agent for the particles. The coloring agent comprises a yellow pigment, pearl powder, a resin adhesive and a corresponding diluent. The coloring agent can be optimized by adding the alcohol-soluble yellow pigment. Through coloring processing, the particles showing yellow and having golden gloss can be obtained; and due to excellent golden gloss, the particles can be applied to multiple fields such as gold paving in tombs, toys, color sand, decoration, lamps, traffic, buildings and the like.

Owner:卢晓谊

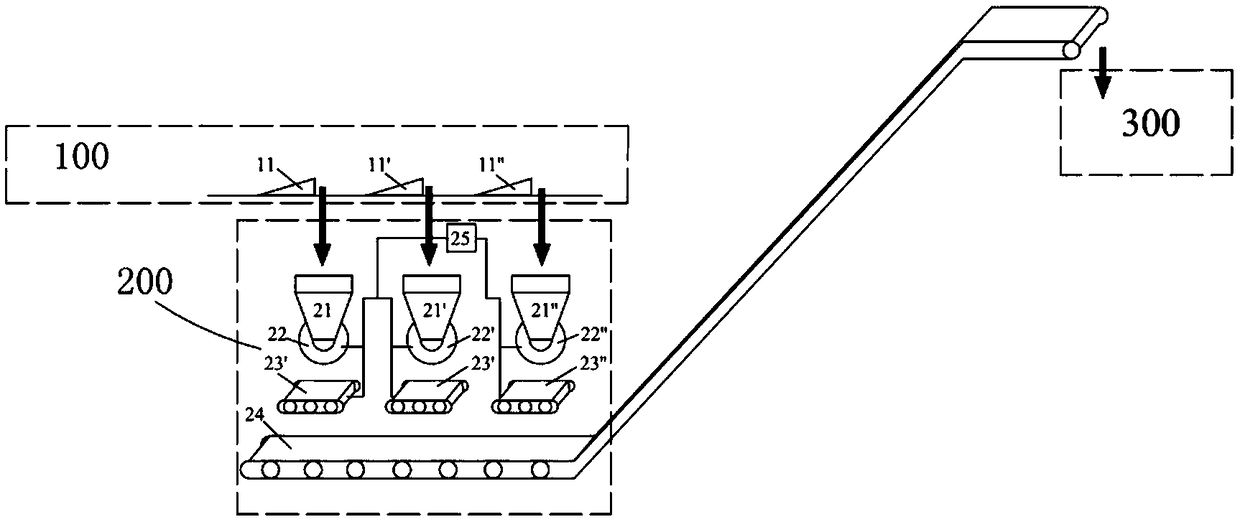

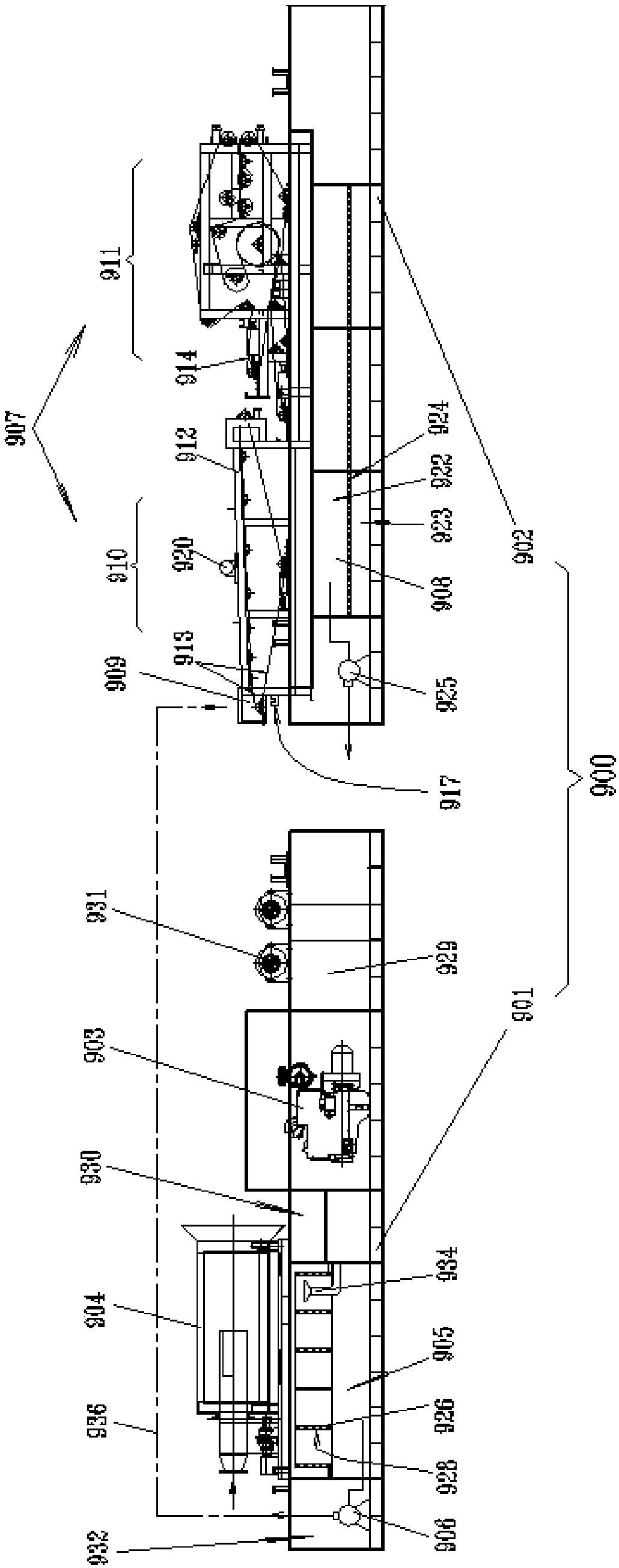

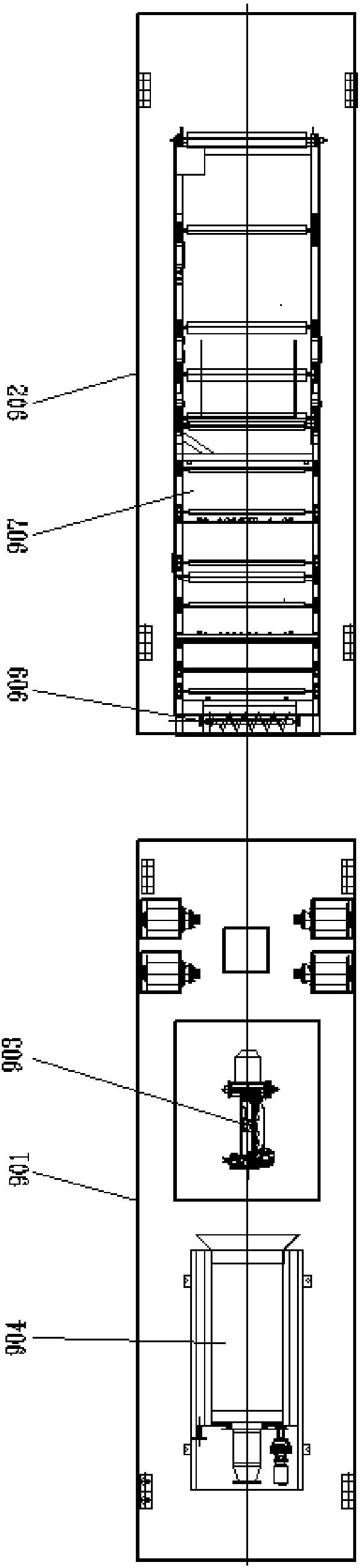

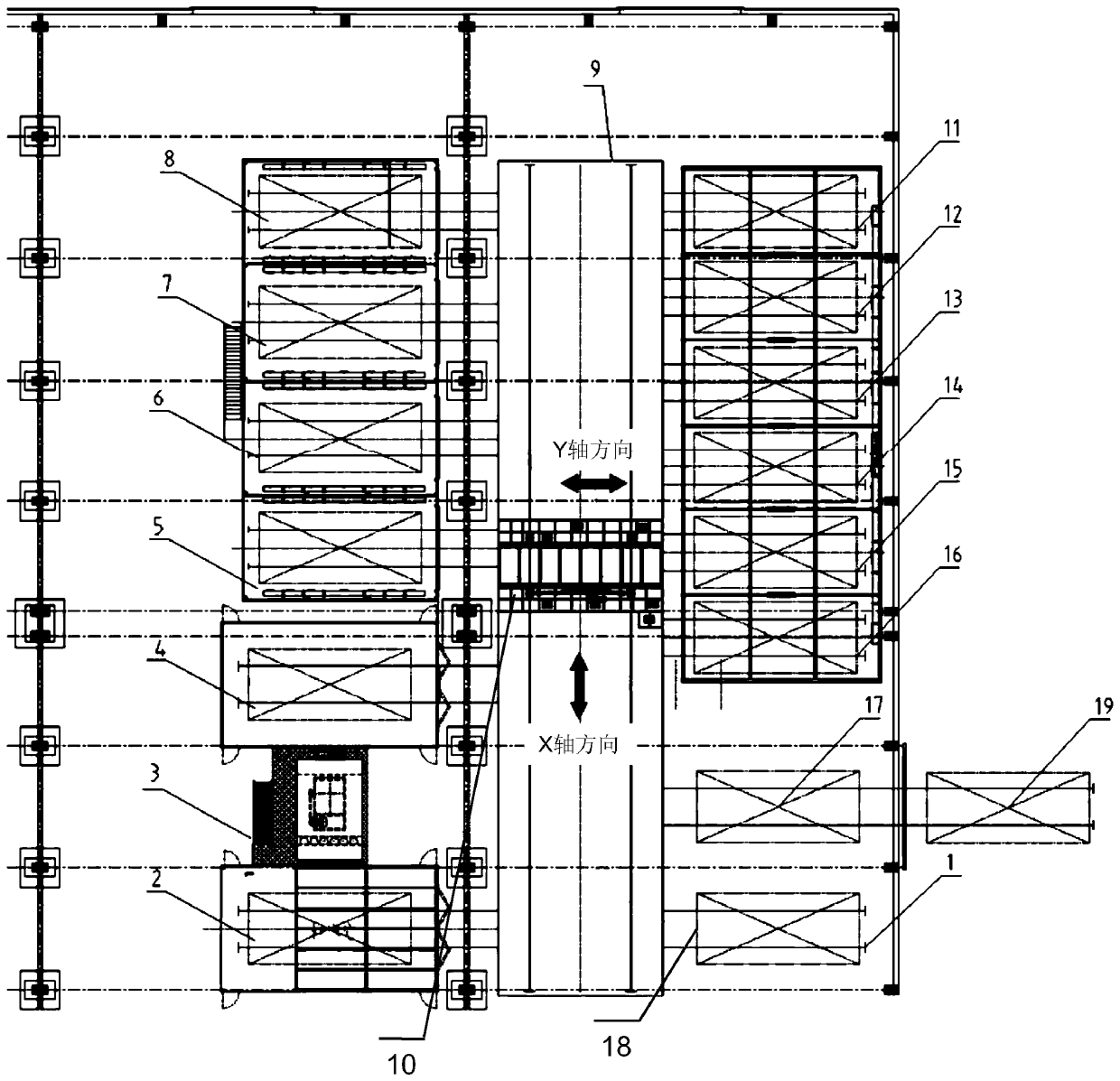

Ore distributing and mixing system based on ports

PendingCN108946205ARealize automatic batchingIncrease productivityLoading/unloadingStack machineGround plane

The invention discloses an ore distributing and mixing system based on ports. The system is characterized in that a feeding system and a stacking system are arranged on the ground, and a distributingsystem is arranged below the ground; the feeding system comprises a belt conveyor feeding system and / or an automobile feeding system; the belt conveyor feeding system and / or the automobile feeding system is connected with an iron ore raw material storage system of the ports; the distributing system comprises a plurality of distributing bins, a belt conveyor and a PLC, wherein the plurality of distributing bins are located below the ground plane, each distributing bin is provided with a feeding machine and an electronic belt scale, the feeding machines are arranged below the distributing bins,the feeding ports of the feeding machines are connected with the discharging ports of the distributing bins, the electronic belt scales are arranged below the discharge ports of the feeding machines,the belt conveyor is arranged below the discharging ends of all the electronic belt scales, and the feeding machines, the electronic belt scales are electrically connected with the PCL correspondingly; and the stacking system comprises a stacking machine, and the receiving end of the stacking machine is connected with the discharging end of the belt conveying conveyor in the distributing system.

Owner:上海慧安科技股份有限公司

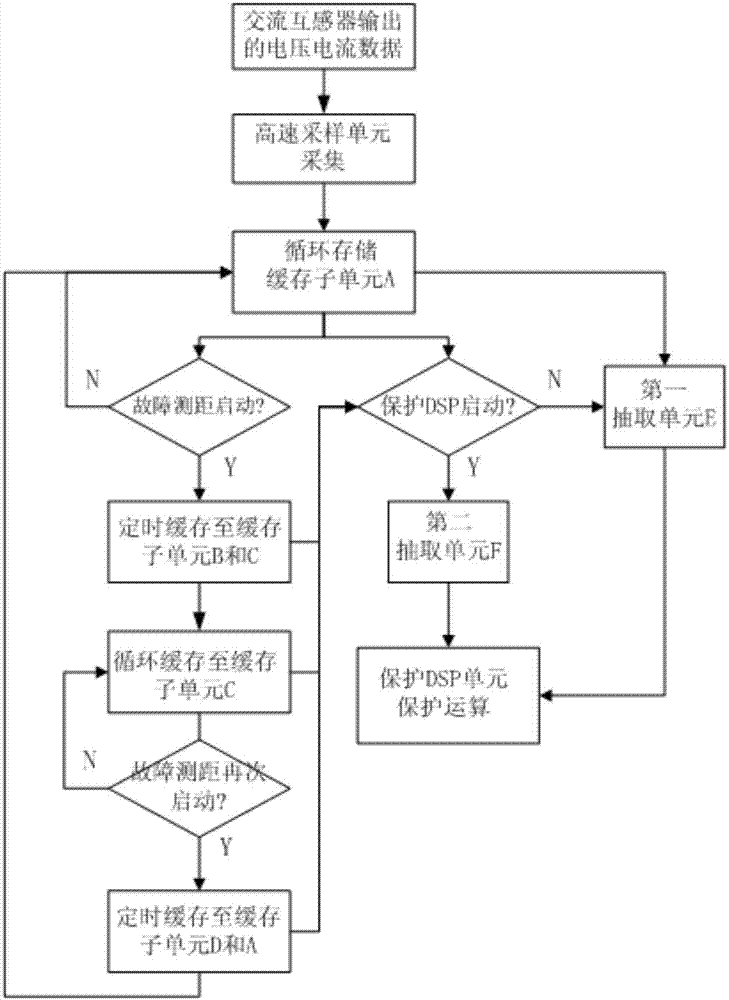

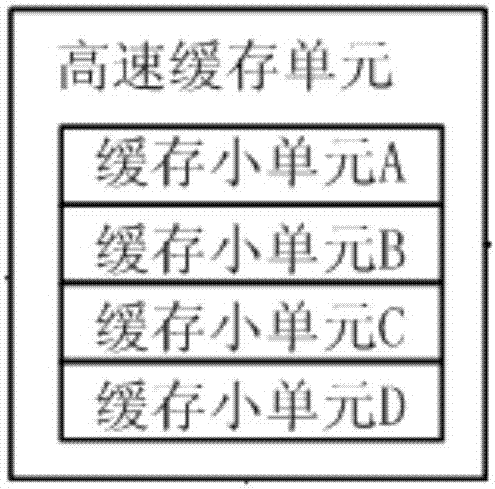

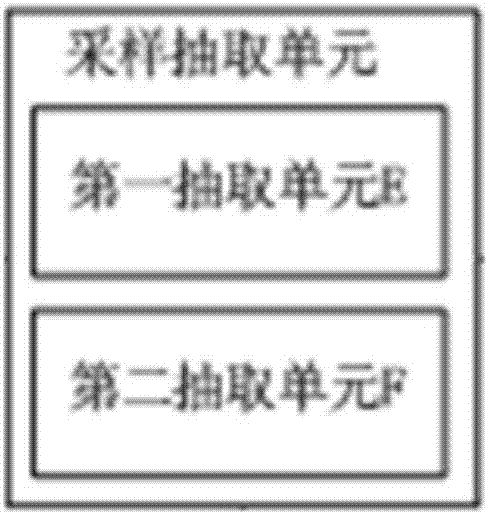

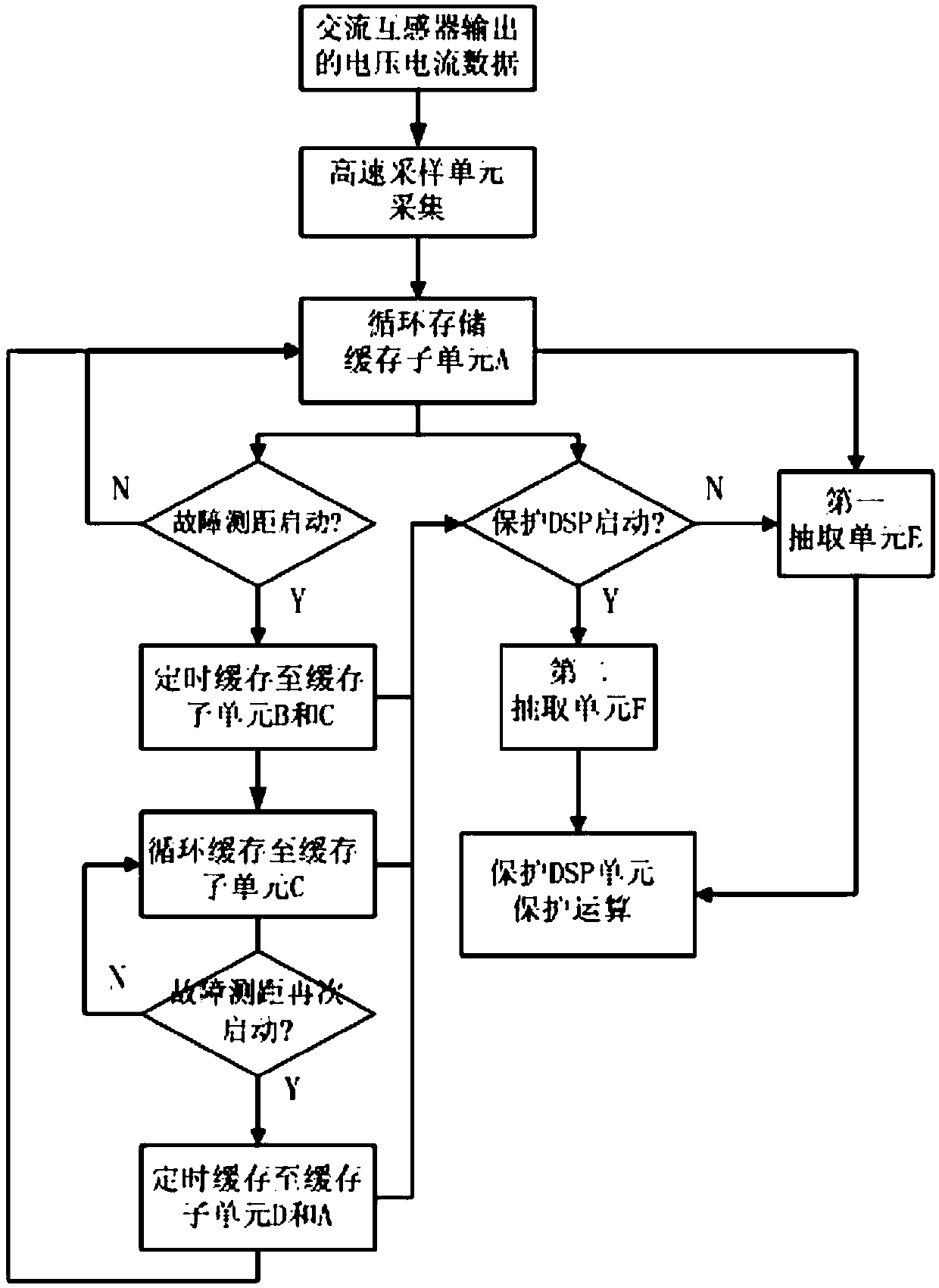

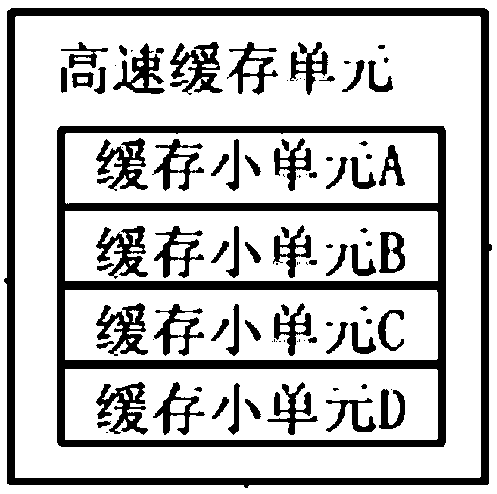

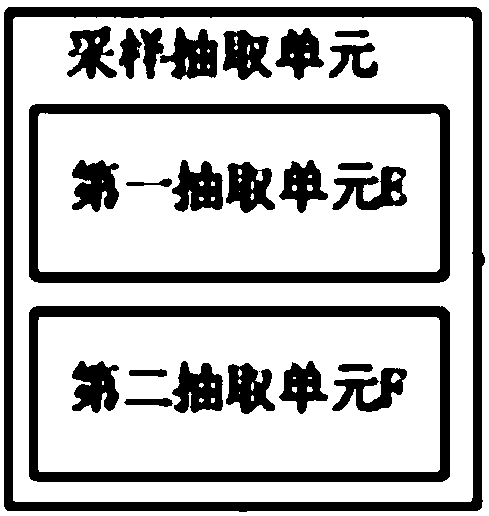

Integrated transmission line protection and traveling wave distance measurement method

ActiveCN107247214AImprove fault location accuracyResolve overriddenFault location by conductor typesCable fault locationData memory

The invention discloses an integrated transmission line protection and traveling wave distance measurement method. Through a protection DSP unit starting criterion and traveling wave DSP unit starting combination, the frequent false starting of traveling wave distance measurement is effectively reduced, through dividing a high speed cache unit into four cache sub units to store traveling wave distance measurement data in a circulated way and timely storing the traveling wave distance measurement data of each time to a data storage device, thus the multiple times of traveling wave distance measurement data with near initiation intervals are not covered, a problem of data coverage or loss caused by frequent starting is effectively solved, through a mode of setting two types of extraction sampling units, the precision of protecting DSP sampling is improved, the fault distance measurement precision of a transmission line is improved, at the same time station resources are saved, and the method has a good application prospect.

Owner:NR ELECTRIC CO LTD +1

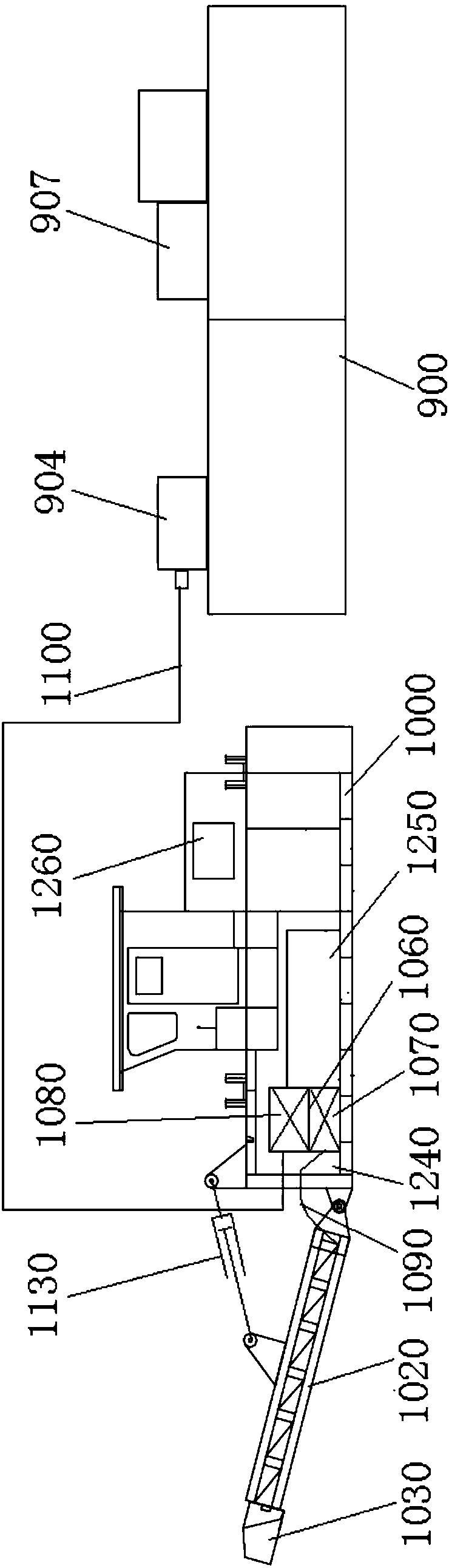

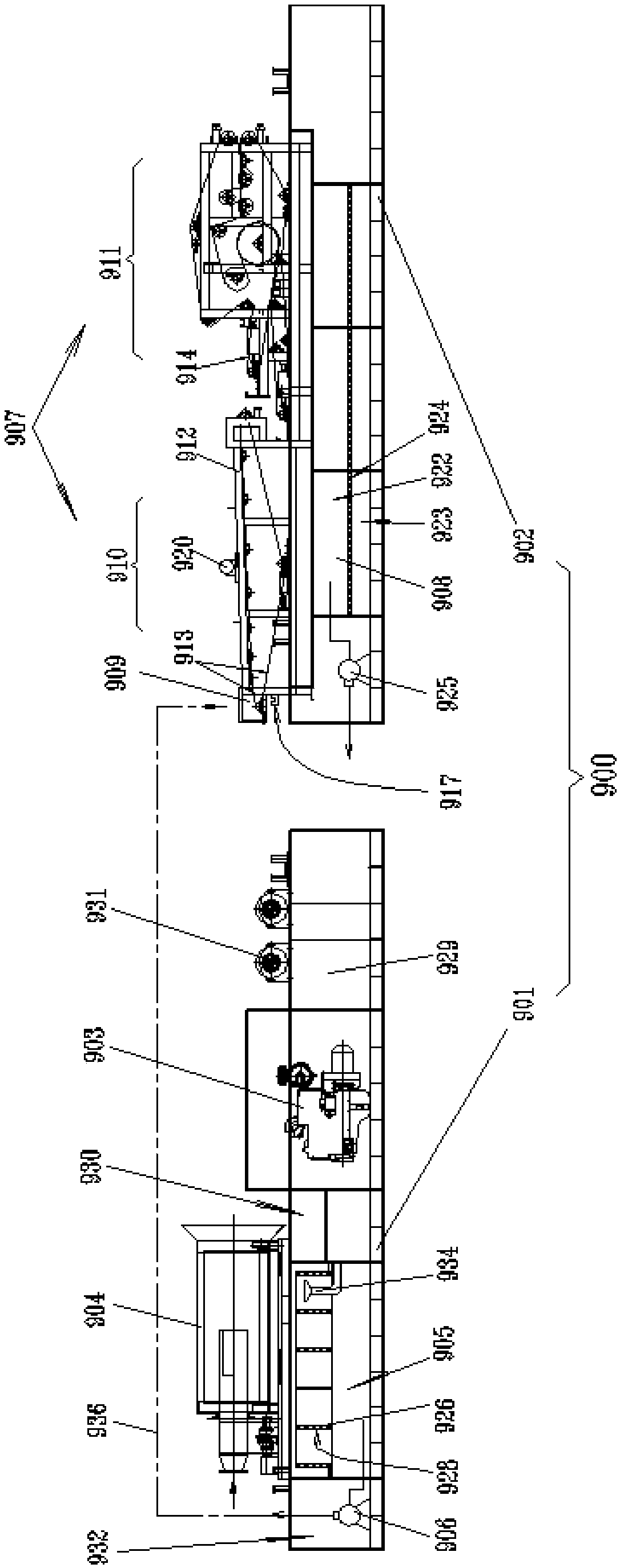

Environment-friendly river sediment dehydration drying boat

PendingCN108275861ALow costSave site resourcesSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSediment FilterLitter

The invention relates to the technical field of river channel cleanout and sediment treatment and discloses an environment-friendly river sediment dehydration drying boat which comprises a boat body and a power system, wherein the power system is arranged on the boat body and is used for providing power to the sediment dehydration drying boat; a sediment / garbage separation device, a sediment concentration tank, a sediment conveying pump, a belt type sediment filter press and a filtering tank are sequentially arranged and connected with the boat body according to a sediment treatment sequence;the sediment / garbage separation device is positioned above the sediment concentration tank; the belt type sediment filter press is positioned above the filtering tank. According to the boat, integralon-line treatment of rapid dehydration, solidification and residual water draining treatment on river sediment can be achieved. Therefore, the purposes of high efficiency and harmless river cleanout and reduction of residual water draining treatment can be achieved.

Owner:江阴市顺通机械技术有限公司 +1

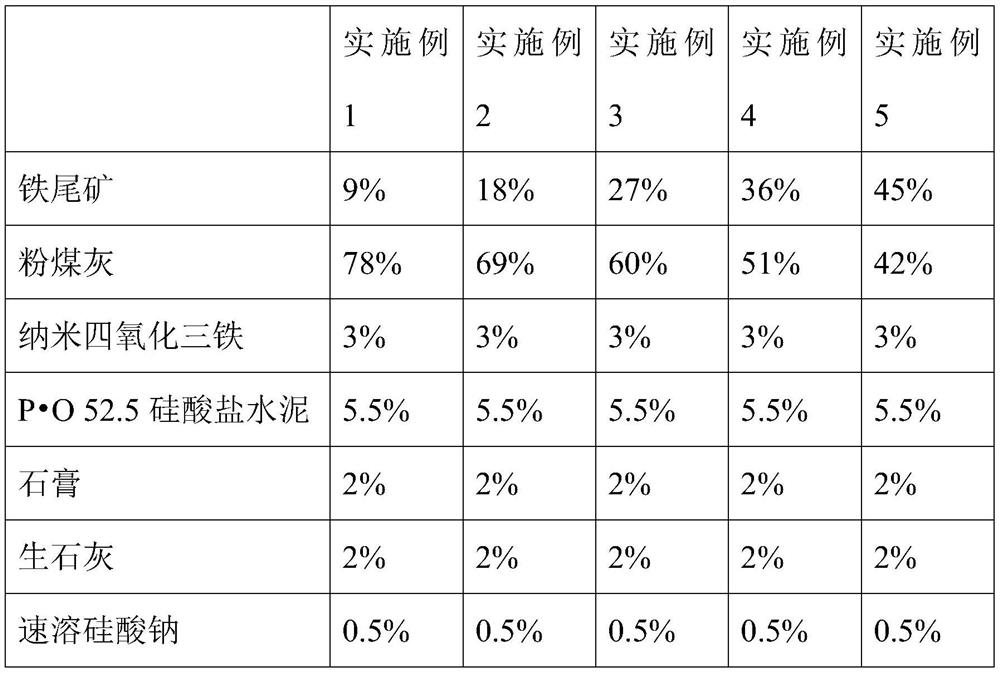

Iron tailing ceramsite and preparation method thereof

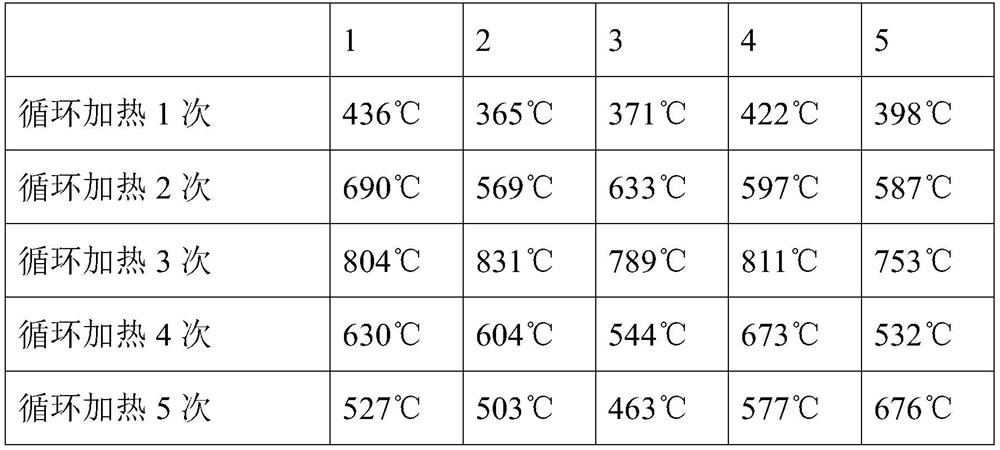

PendingCN114133213ARaise the sintering temperatureFast heatingCeramic materials productionClaywaresMicrowave ovenEnvironmental engineering

The invention relates to the field of comprehensive utilization of iron tailing resources, and mainly relates to iron tailing ceramsite and a preparation method thereof. The method comprises the following steps: uniformly stirring raw materials according to a given mass percentage, adding water, mixing to obtain a mixed material, putting the mixed material into a disc pelletizer to prepare an iron tailing ceramsite spherical material, drying the obtained ceramsite, cooling to room temperature, putting into an industrial microwave oven, and carrying out microwave heating treatment to obtain the iron tailing ceramsite. And cooling to obtain the iron tailing spherical ceramsite with good grain composition. According to the method, the solid waste iron tailings can be fully utilized, the additional value of the solid waste can be greatly increased, resource recycling of the solid waste is achieved, site resources occupied by landfill are reduced, and meanwhile contribution is made to environmental protection.

Owner:HEFEI UNIV OF TECH +1

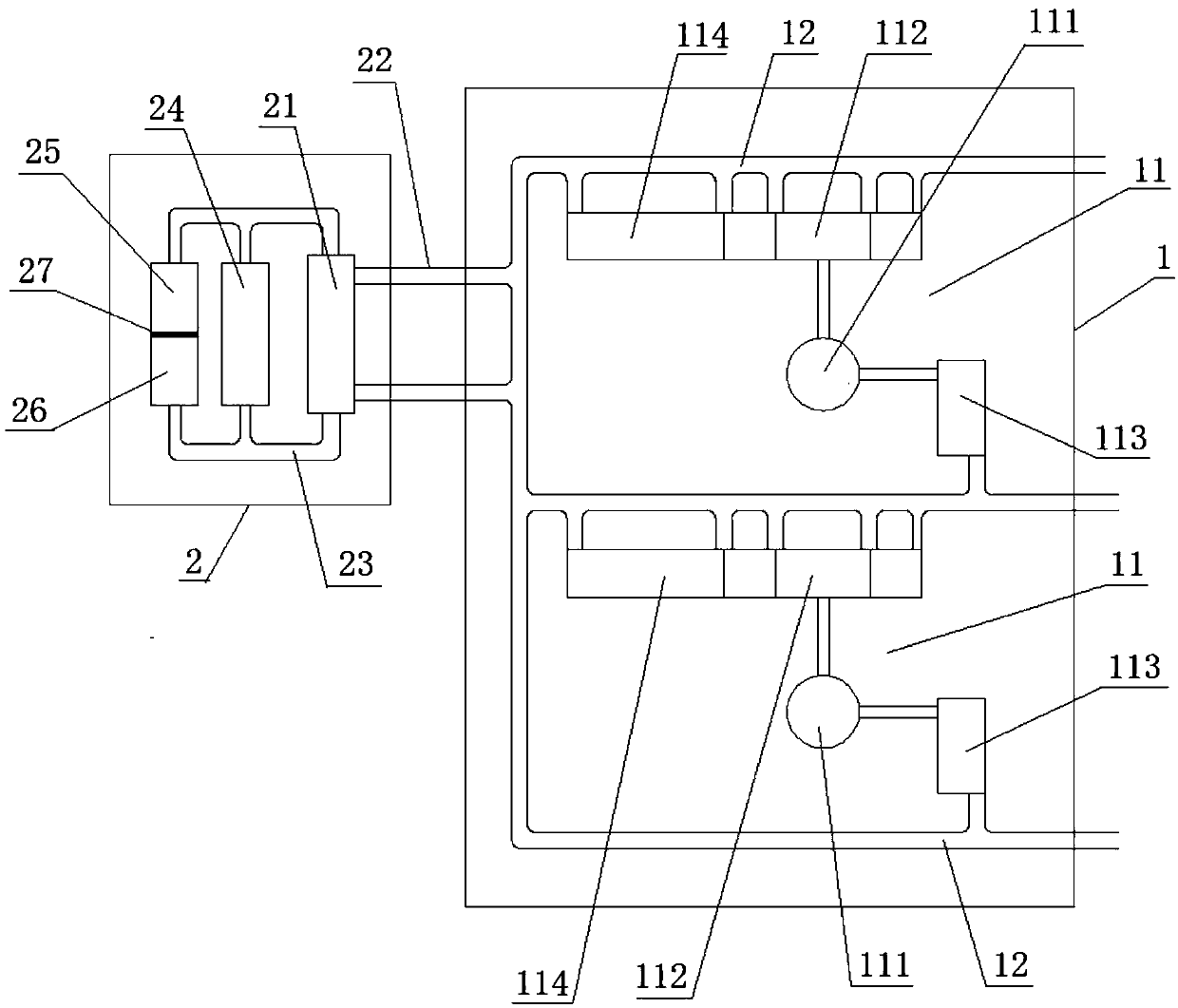

Supporting structure for double-head milling machine

InactiveCN106334949AImprove work efficiencyImprove stabilityLarge fixed membersMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a supporting structure for a double-head milling machine. The supporting structure for the double-head milling machine is used for supporting milling head mechanisms and a workpiece. The supporting structure comprises a base and a pedestal used for supporting the workpiece. The base comprises a main base body and two auxiliary base bodies. The milling head mechanisms are arranged on the auxiliary base bodies. The cross section of the base is in a crossed shape. The two auxiliary base bodies are arranged at the left edge position and the right edge position of the middle of the main base body correspondingly and are symmetrically distributed. The pedestal is arranged on the main base body and is movably connected with the main base body. The main base body is detachably connected with the auxiliary base bodies. The supporting structure has the beneficial effects that stability of the whole double-head milling machine is improved, the operation precision of the workpiece is improved, the labor intensity of operators is effectively lowered, the work efficiency of the double-head milling machine is improved, the application range is wide, the functions of automatic chip removing and waste chip recycling can be achieved, and the production cost is reduced.

Owner:宁波川田精密机械有限公司

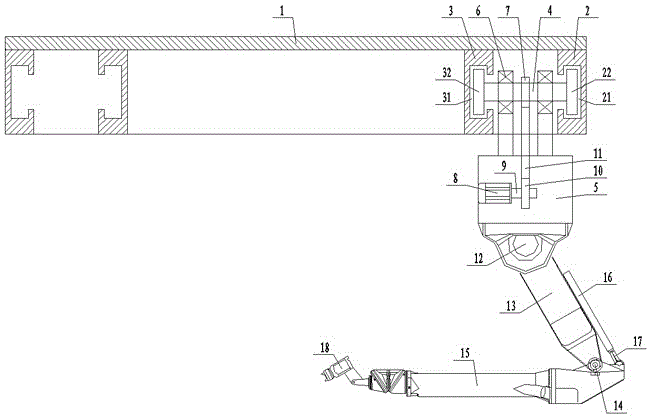

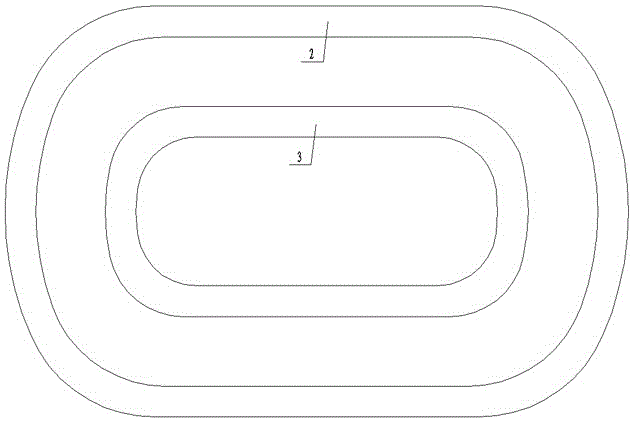

Suspension type car seat three-dimensional welding robot

InactiveCN106736125ACompact structureSave site resourcesWelding/cutting auxillary devicesAuxillary welding devicesDrive motorMotor shaft

The invention discloses a suspension type car seat three-dimensional welding robot which comprises a roof, an outer ring rail and an inner ring rail. The outer ring rail and the inner ring rail are concentrically arranged on the roof, an outer sliding groove is formed in the outer ring rail, and an outer sliding wheel is arranged in the outer sliding groove in a sliding manner; an inner sliding groove is formed in the inner ring rail, an inner sliding wheel is arranged in the inner sliding groove in a sliding manner, and the outer sliding wheel is connected with the inner sliding wheel through a connecting shaft; the upper end of a machine base is rotationally connected with the connecting shaft through two bearing blocks, a driven chain wheel is arranged at the position, between the two bearing blocks, on the connecting shaft, a driving motor is arranged in the machine base, and a driving chain wheel is arranged on a motor shaft of the driving motor; and the driving chain wheel is connected with the driven chain wheel through a chain, an angle rotating motor is arranged at the lower end of the machine base, and the upper end of a first swing arm is connected with the angle rotating motor.

Owner:YANCHENG GAOYUE MACHINERY

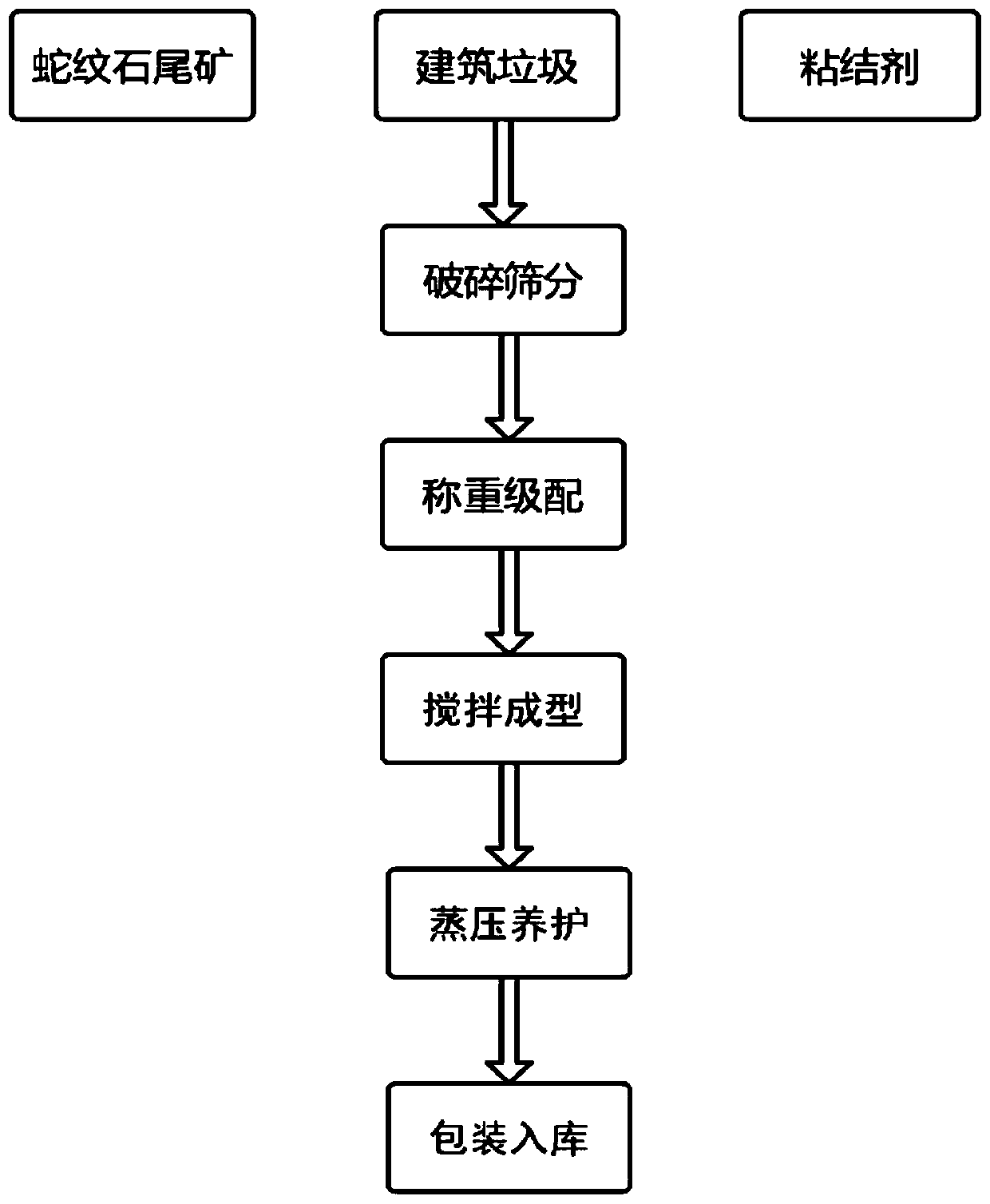

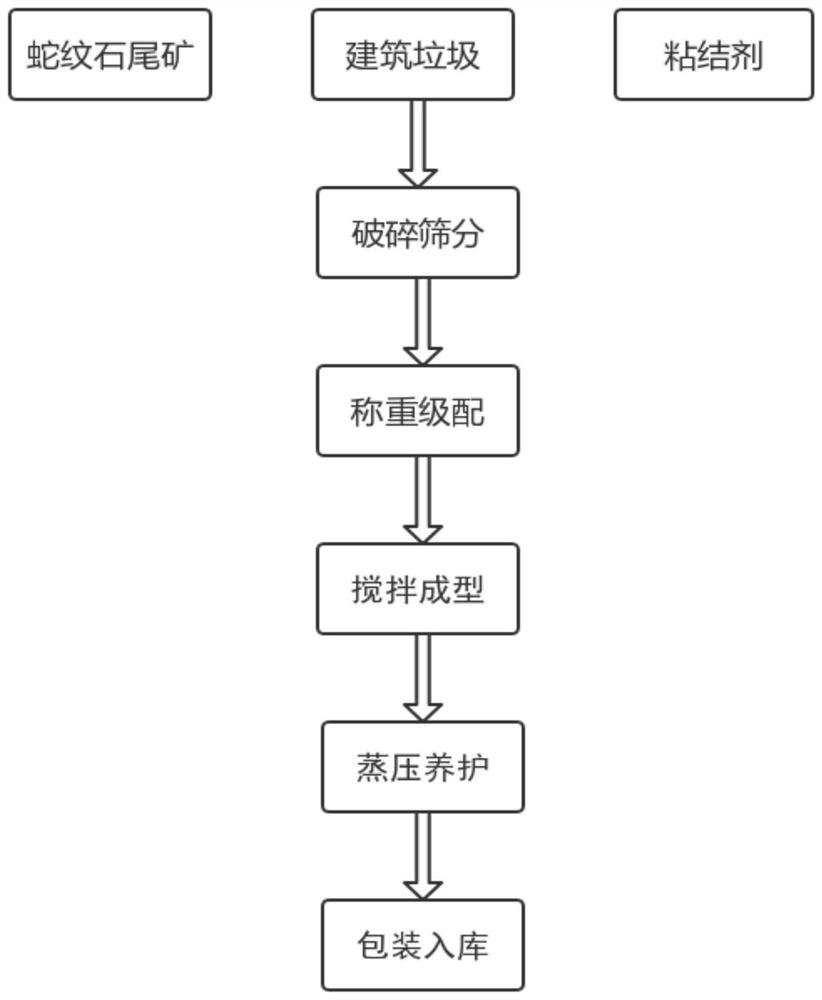

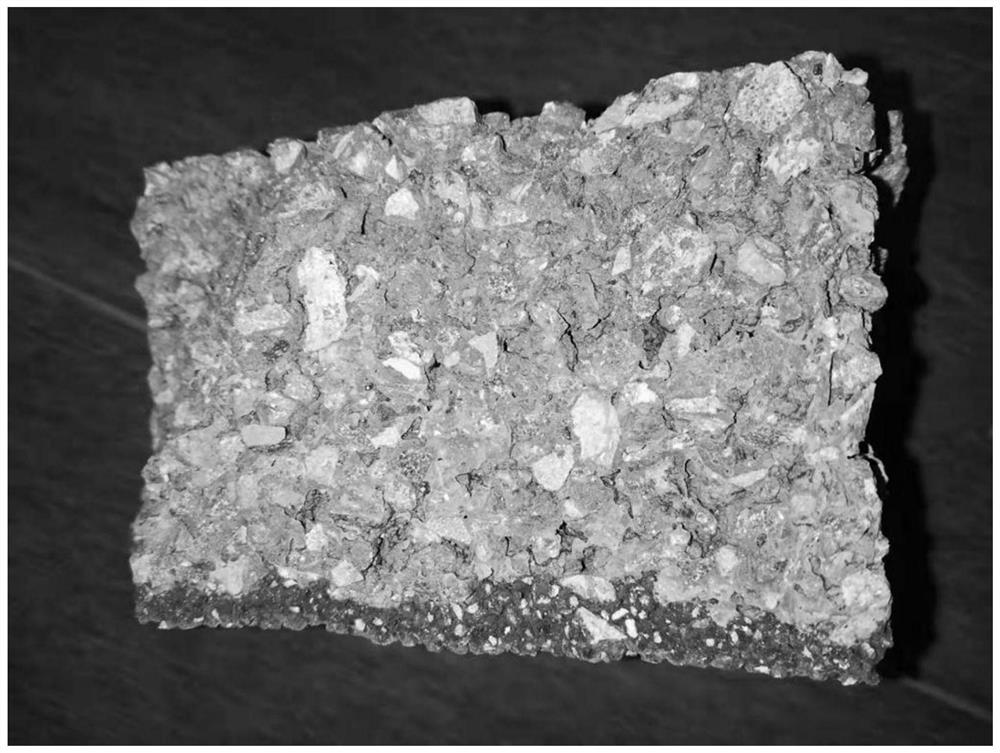

Water-permeable brick prepared from serpentine tailings and construction waste and preparation method thereof

ActiveCN110981396AIncrease added valueRealize recycling of resourcesSolid waste managementCeramic shaping apparatusCompression moldingBrick

A water-permeable brick prepared from serpentine tailings and construction waste and a preparation method thereof are disclosed. The serpentine tailings and construction waste are adopted as raw materials and subjected to steps of crushing, sieving, grading, compression molding by utilizing an efficient adhesive and solid waste particles, and finished product curing, and the prepared unfired water-permeable brick has indexes superior to those stipulated by national standards. The serpentine tailings and construction waste which are solid waste can be fully utilized, the additional value of thesolid waste is greatly improved, resource recycling of the solid waste is achieved, site resources occupied by landfill are reduced and the brick has important economic, social and ecological environmental protection significance.

Owner:江苏未名环保科技有限公司

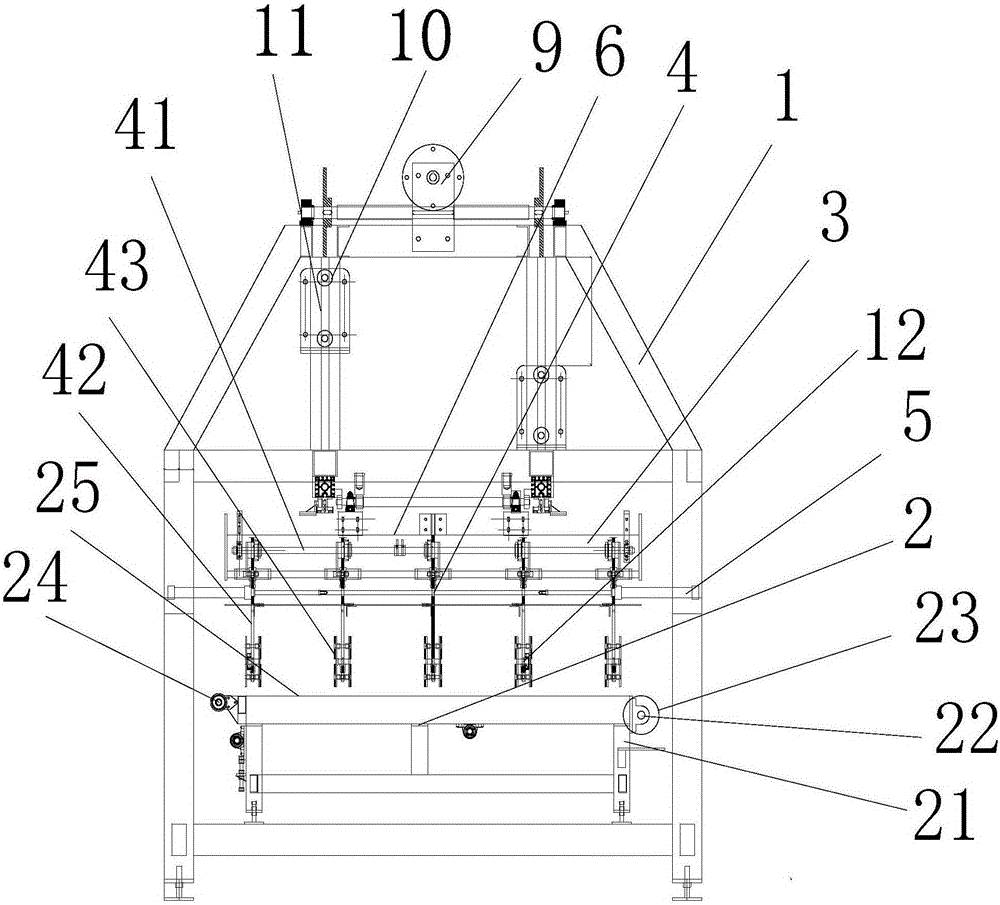

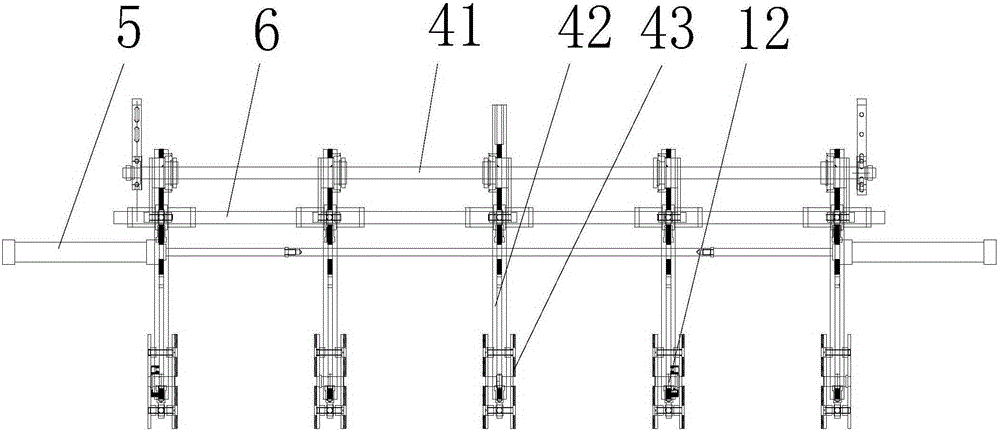

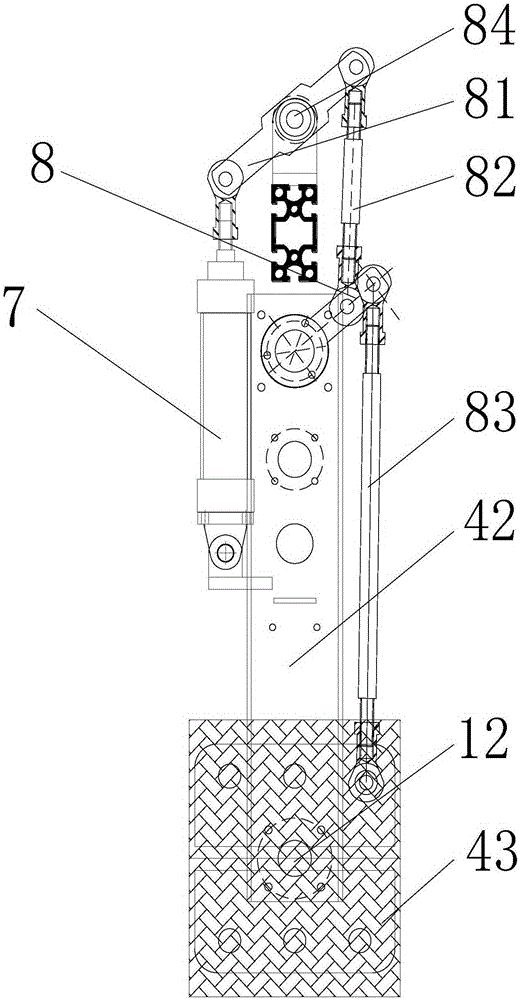

Overhead green brick turnover equipment used for hollow brick production

ActiveCN105329648AImprove turning efficiencySimple structureConveyor partsBrickProgrammable logic controller

The invention provides overhead green brick turnover equipment used for hollow brick production, and relates to the technical field of mechanical equipment for hollow brick production. The overhead green brick turnover equipment comprises a bracket, a transport unit and a turnover mechanism for turning over and steering green hollow bricks, wherein the transport unit is mounted below the bracket; the turnover mechanism is mounted on the bracket; the transport unit and the turnover mechanism are controlled by a PLC (programmable logic controller) and a servo mechanism to cooperatively work; the turnover mechanism is an overhead turnover mechanism for vertically rotating the green hollow bricks in air by 90 degrees. The overhead green brick turnover equipment provided by the invention is high in green brick turnover efficiency for hollow bricks, is small in floor space, relatively low in manufacturing cost and simple in structure, and has a wide market prospect.

Owner:CHONGQING ZHUOGONG TECH

High-performance artificial marble

The invention discloses a high-performance artificial marble. The high-performance artificial marble comprises the following raw materials in parts by weight: 10-15 parts of matrix resin, 50-70 partsof a filler, 0.6-0.8 parts of a curing agent, 0.2-0.4 parts of an accelerator, 4-5 parts of a pigment, and 10-20 parts of a flame retardant. The artificial marble of the invention mainly uses unsaturated polyester resin, modified epoxy resin and silicone modified polyurethane resin as binders, and uses marble waste rock powder, modified nickel slag and modified waste glass as the filler. various pigments, the curing agents and the accelerators are added, a stone product is made by stirring, forming, solidifying and polishing, the comprehensive mechanical properties of artificial marble can begreatly improved, the chance of cracks is effectively reduced, the wearing is not easily generated, and the obtained artificial marble has better gloss so as to achieve the comfortable visual experience of the human body and the space decoration effect without light pollution; the flame retardant performance is superior, and the comprehensive performance of the artificial marble board is improved.

Owner:佛山市欧泊石业有限公司

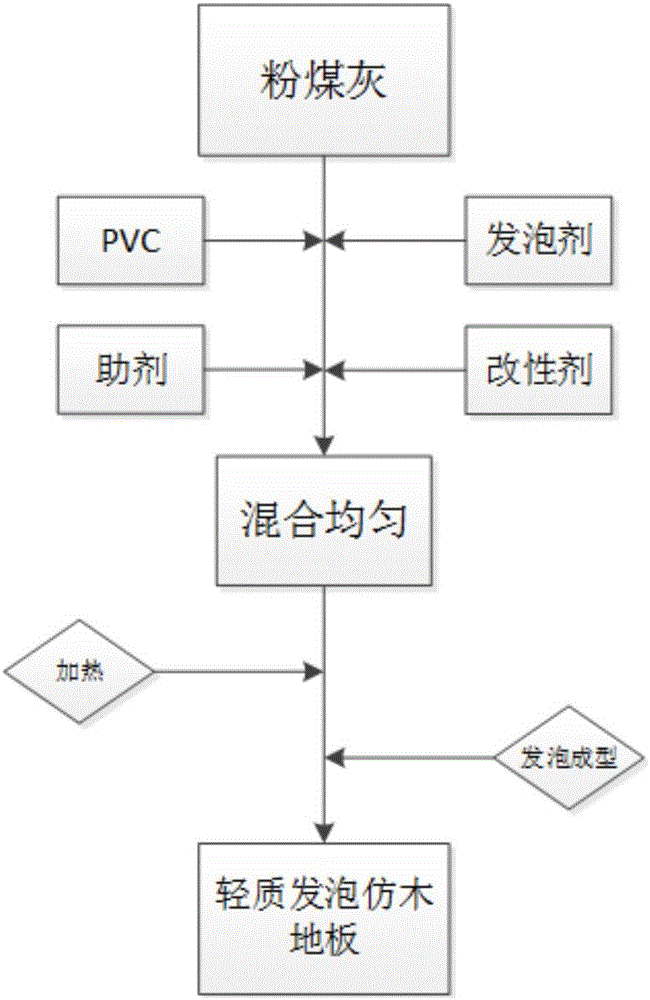

Light foaming imitation wood floor and preparation method thereof

The invention relates to an imitation wood floor. The imitation wood floor is prepared from fly ash, PVC, a foaming agent, an auxiliary and a modifying agent. The wood floor is small in self weight, convenient to use, simple in preparation method and capable of greatly saving manpower and material resources compared with other types of imitation wood floors; the imitation wood floor adopts the fly ash as a raw material, recycling of solid waste is achieved, site sources occupied due to landfilling is decreased and thus being beneficial for being popularized in practice.

Owner:PEKING UNIV

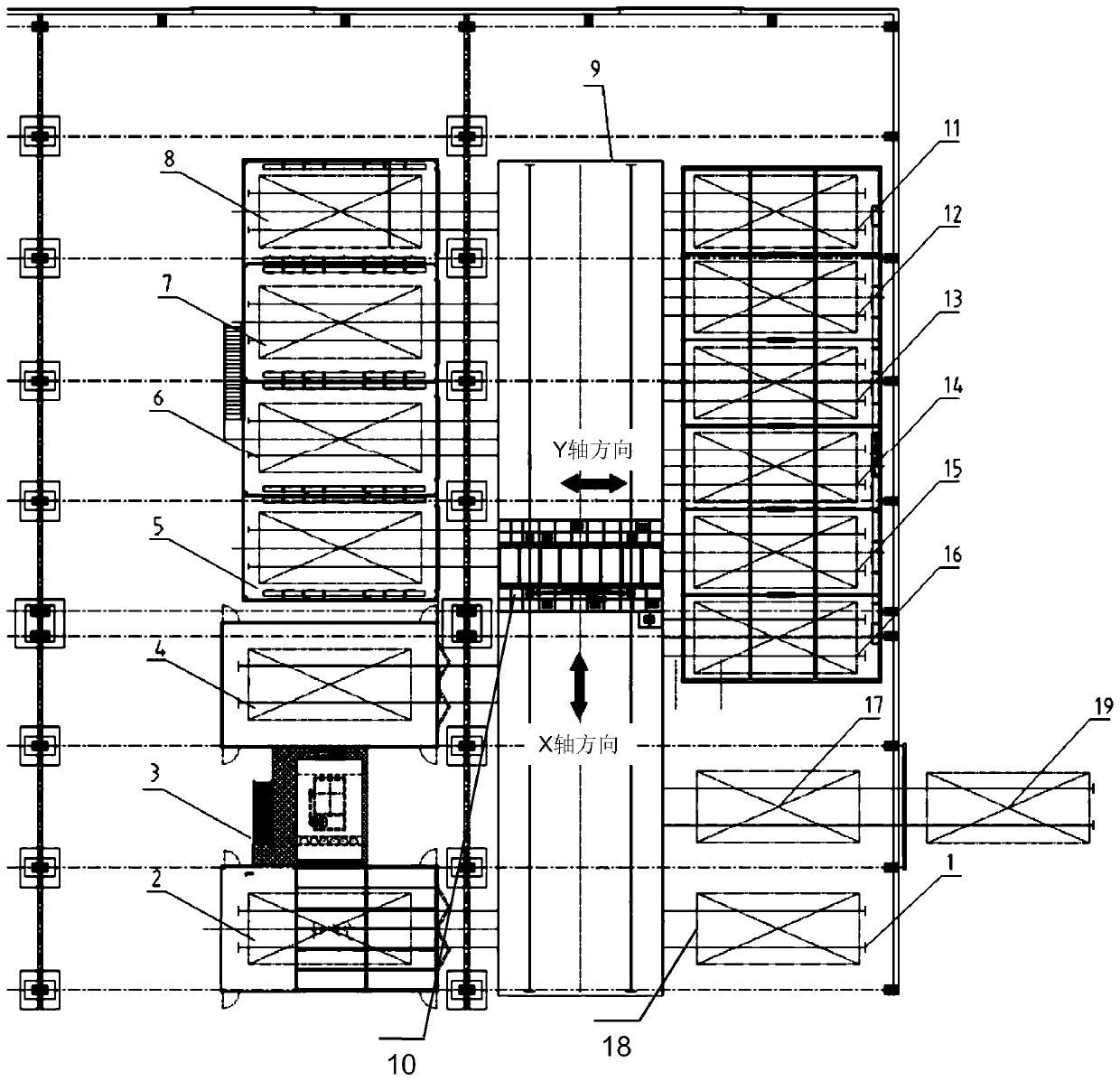

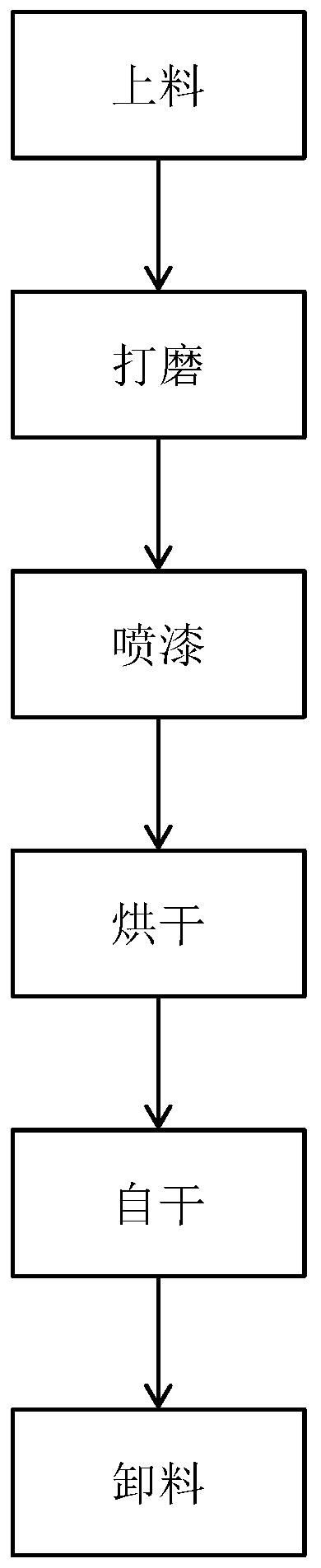

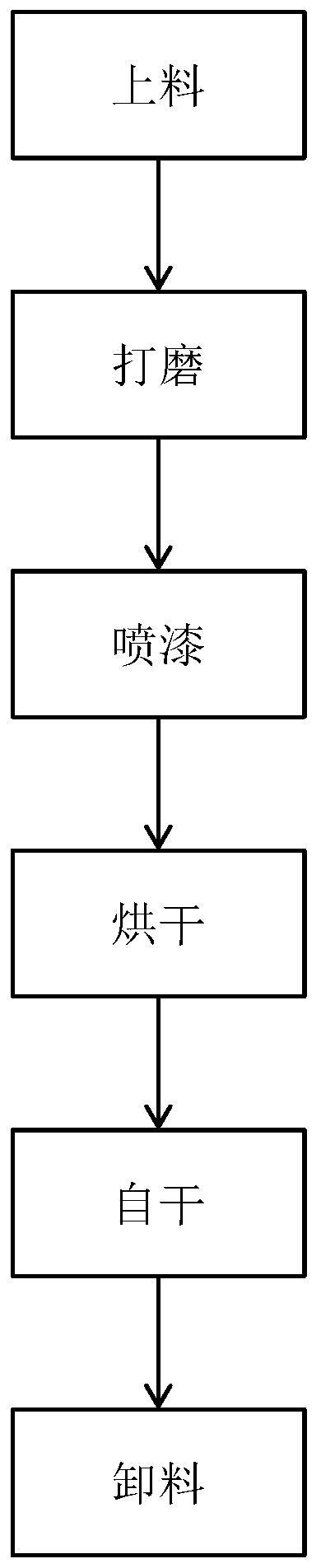

Painting process flow for product painting

The invention discloses a painting process flow for product painting; a product on a feeding station is moved to a polishing chamber station by a power trolley for surface cleaning operation, the product is moved to a painting chamber station by the power trolley for painting operation according to requirements after completion, the product is moved to a drying chamber station by the power trolleyfor automatic drying according to paint drying requirements after completion, and the product is moved to a self-drying chamber station by the power trolley for drying after completion; after completion, the product is moved to a unloading buffer station or a unloading station by the power trolley to load and unload the product after painting is completed, and the power trolley returns to the loading station to cycle the next batch of products, and the cycle reciprocates accordingly. According to the invention, the problem of circulation among each working procedure of a workshop painting assembly line is solved, and the problem that the processing time of each working procedure is different is further solved, so that the assembly line can be circulated well.

Owner:SHANGHAI ZHENHUA PORT MACHINARY HEAVY IND CO LTD

Underground nuclear power station with low and medium radioactive waste disposal system and disposal method thereof

PendingCN109637684AImprove construction economySolve the problem of site selectionNuclear energy generationRadioactive decontaminationWater dischargeWastewater

The invention relates to the technical field of underground nuclear power plants, and discloses an underground nuclear power plant with a low-medium radioactive waste disposal system, which comprisesa power generation area and a waste disposal area, wherein the power generation area comprises a plurality of single-pile nuclear power systems, and each single-pile nuclear power system comprises a plurality of power plants, the waste disposal area comprises an SRTF site radioactive waste treatment facility which is connected with a power generation area traffic tunnel through a waste transfer tunnel, the bottom of the SRTF site radioactive waste treatment facility is provided with a discharge water tank communicated with a site waste water discharge system of the power generation area, the SRTF site waste discharge treatment facility is also connected with a low radioactive waste treatment tunnel, a medium radioactive waste disposal tunnel and a spent fuel dry storage area. The inventionfurther discloses a disposal method of the underground nuclear power station with the low-medium radioactive waste disposal system. According to the underground nuclear power station with the low-medium-radioactive waste disposal system and the disposal method thereof, the problem of site selection of the low-medium-radioactive disposal site is solved, meanwhile, the centralization of the waste disposal function is achieved, the excavation of a cave is reduced, and the problem of nuclear security in the process of outward transportation of radioactive waste is avoided.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Preparation method of high-performance artificial marble

The invention discloses a preparation method of a high-performance artificial marble. The artificial marble comprises the following raw materials in parts by weight: 10-15 parts of a matrix resin, 50-70 parts of a filler, 0.6-0.8 part of a curing agent, 0.2-0.4 part of an accelerator, 4-5 parts of a pigment, and 10-20 parts of a flame retardant. In the preparation method, an unsaturated polyesterresin, a modified epoxy resin and an organosilicon modified polyurethane resin are used as a binder, marble waste stone powder, modified nickel slag and modified waste glass are used as the filler, various pigments, the curing agent and the accelerator are added, a stone product, namely the artificial marble, is made by stirring, forming, curing and polishing. Comprehensive mechanical properties of the artificial marble can be greatly improved, the probability of crack appearances is effectively reduced, the artificial marble is not easy to wear, and the gloss of the obtained artificial marbleis relatively good, so that the comfortable visual feeling of the human body and the space decoration effect without light pollution are achieved; and the fire-resistant property is superior, so thatthe comprehensive properties of an artificial marble slab are improved.

Owner:佛山市欧泊石业有限公司

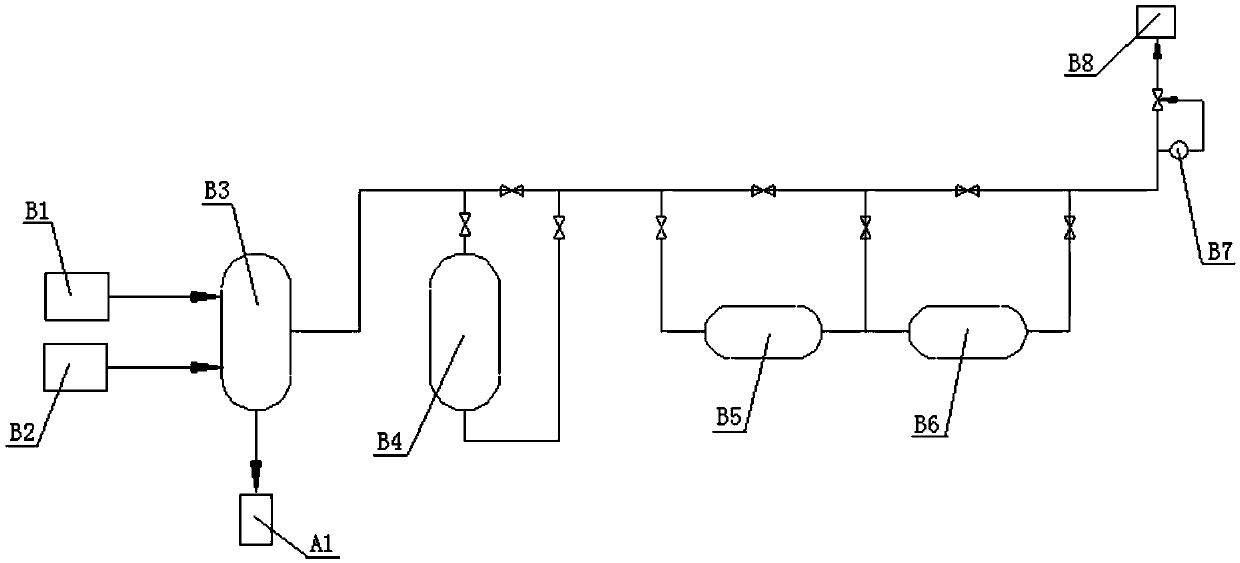

High-temperature liquid slag granulation and waste heat recovery method

InactiveCN111100957ATake advantage ofFully consider the use ofRecycling and recovery technologiesProcess efficiency improvementThermodynamicsWater vapor

The invention discloses a high-temperature liquid slag granulation and waste heat recovery method. Low-temperature air, water and low-temperature carbon dioxide are sequentially selected as heat exchange media, and a three-stage three-medium method is adopted for achieving heat exchange with high-temperature liquid slag to obtain normal-temperature solid slag and heat exchange media absorbing heat. The high-temperature liquid slag granulation and waste heat recovery method specifically comprises the steps that the low-temperature air is adopted to cool slag droplets formed after the high-temperature liquid slag is crushed to form high-temperature solid slag and high-temperature air; the water is adopted to cool the high-temperature solid slag to obtain medium-temperature solid slag and high-temperature water vapor; and countercurrent heat exchange is carried out between the low-temperature carbon dioxide and medium-temperature solid slag to obtain normal-temperature solid slag and high-temperature carbon dioxide. According to the split slag comprehensive utilization method combining centrifugal granulation and three-stage heat exchange, the water does not directly make contact withthe slag, the energy and resource properties of the hot slag are sufficiently considered, through multi-step cooling, the heat in the hot slag can be fully utilized, the low-temperature and high-temperature slag which can be used as raw materials for new plates and building floors can be obtained, and great significance is achieved for practice and popularization.

Owner:PEKING UNIV

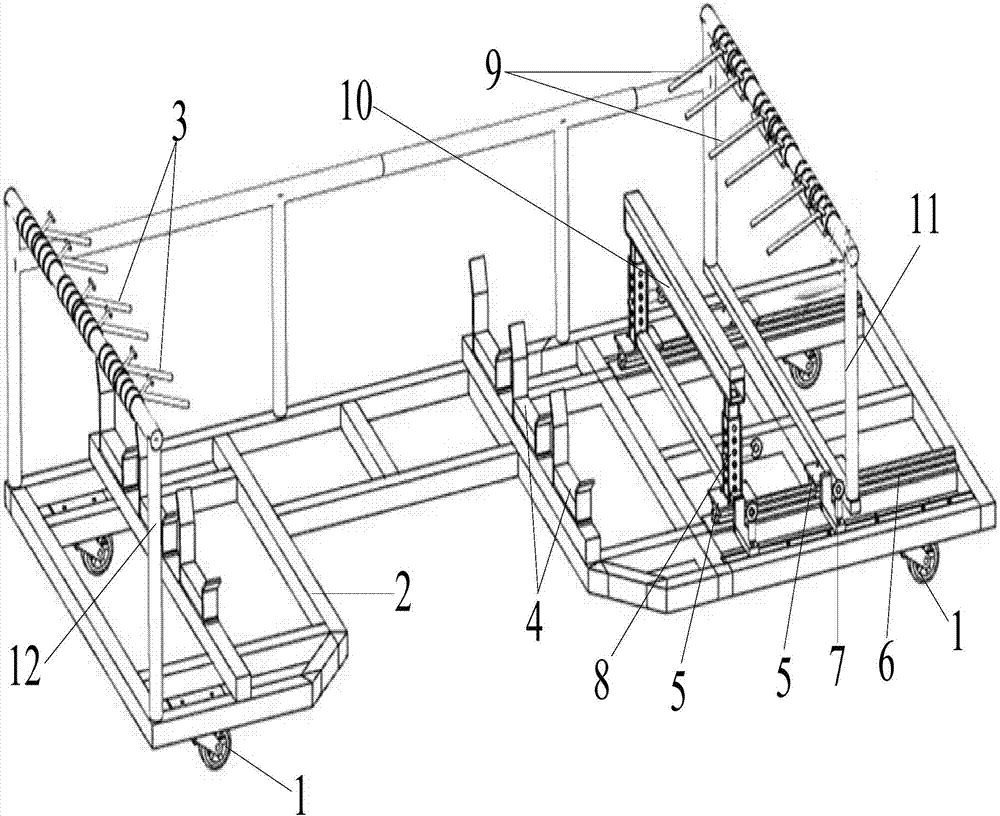

Car flexible side-frame material box

ActiveCN107161186AImprove compatibilityReduce in quantityInternal combustion piston enginesHand carts with multiple axesStructural engineeringMechanical engineering

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Wastewater purification process in incineration furnace slag treatment process

InactiveCN111747595ASave site resourcesImprove cleaning efficiencyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesActivated carbonSlag

The invention provides a wastewater purification process in an incineration furnace slag treatment process. The wastewater purification process comprises the following steps: oil stain removal by an air flotation method, pH value adjustment treatment, chemical precipitation treatment and filtration treatment, layer filtration treatment, cyclic concentration treatment, centrifugal filtration treatment, nanofiltration treatment, heavy metal recapture treatment, magnetic metal separation treatment and gravity metal reselection treatment. According to the process, the oil stain in the wastewater is effectively removed by removing the oil stain through an air flotation method; in cooperation with activated carbon adsorption filtration in subsequent layer filtration treatment, oil stains in thewastewater can be completely removed; large-particle heavy metal precipitates contained in the wastewater can be filtered through pH value regulation treatment, chemical precipitation treatment and filtration treatment; micromolecular heavy metals contained in the wastewater can be removed through centrifugal filtration treatment, ultrafiltration membrane treatment, nanofiltration treatment and heavy metal recapture treatment, the treated wastewater can reach the discharge standard, wastewater purification treatment can be performed without using more sites, and site resources are effectivelysaved.

Owner:温州桂森环境科技有限公司

An integrated transmission line protection and traveling wave ranging method

ActiveCN107247214BImprove fault location accuracySolve the lossFault location by conductor typesCable fault locationData memory

The invention discloses an integrated transmission line protection and traveling wave distance measurement method. Through a protection DSP unit starting criterion and traveling wave DSP unit starting combination, the frequent false starting of traveling wave distance measurement is effectively reduced, through dividing a high speed cache unit into four cache sub units to store traveling wave distance measurement data in a circulated way and timely storing the traveling wave distance measurement data of each time to a data storage device, thus the multiple times of traveling wave distance measurement data with near initiation intervals are not covered, a problem of data coverage or loss caused by frequent starting is effectively solved, through a mode of setting two types of extraction sampling units, the precision of protecting DSP sampling is improved, the fault distance measurement precision of a transmission line is improved, at the same time station resources are saved, and the method has a good application prospect.

Owner:NR ELECTRIC CO LTD +1

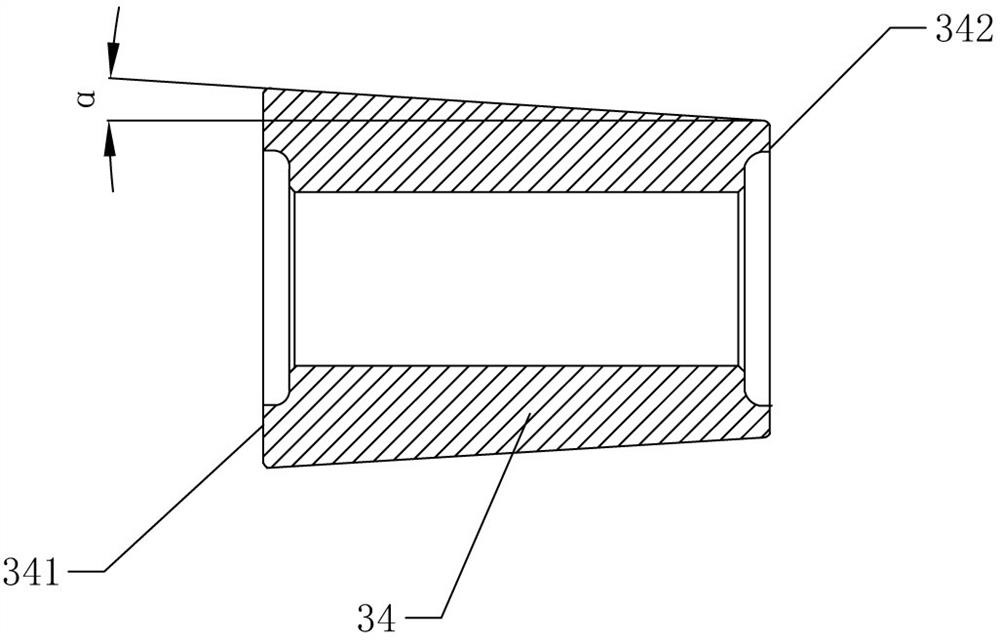

Turning conveying track adapting to rapid heating steel billet manufacturing

PendingCN112857036AShorten the lengthShorten delivery timeFurnace typesStructural engineeringIndustrial engineering

The invention discloses a turning conveying track adapting to rapid heating steel billet manufacturing. The turning conveying track comprises a stepping furnace, an arc-shaped conveying track is arranged at a discharging opening of the stepping furnace and comprises an arc-shaped inner wall and an arc-shaped outer wall, and an arc-shaped channel is formed between the arc-shaped inner wall and the arc-shaped outer wall. Multiple conical rollers are sequentially arranged in the arc-shaped channel along the arc-shaped conveying track and rotationally connected to the arc-shaped conveying track through rotating shafts, the arc-shaped conveying track is provided with a driving mechanism, the driving mechanism drives the rotating shafts to rotate, the ends, close to the arc-shaped inner wall, of the conical rollers are small ends, the ends, close to the arc-shaped outer wall, of the conical rollers are large ends, and the diameters of the conical rollers are gradually reduced from the large ends to the small ends. The turning conveying track has the following advantages and effects that in the scheme, a new mechanical structure is utilized, the arc-shaped conveying track is adopted to realize conveying reversing, the overall length of conveying is reduced, the length required by a plant can be greatly reduced, the turning conveying track has the effects of reducing the occupied area, saving site resources and effectively reducing the cost, and production efficiency is quite high.

Owner:宁波恒胜新材料科技有限公司

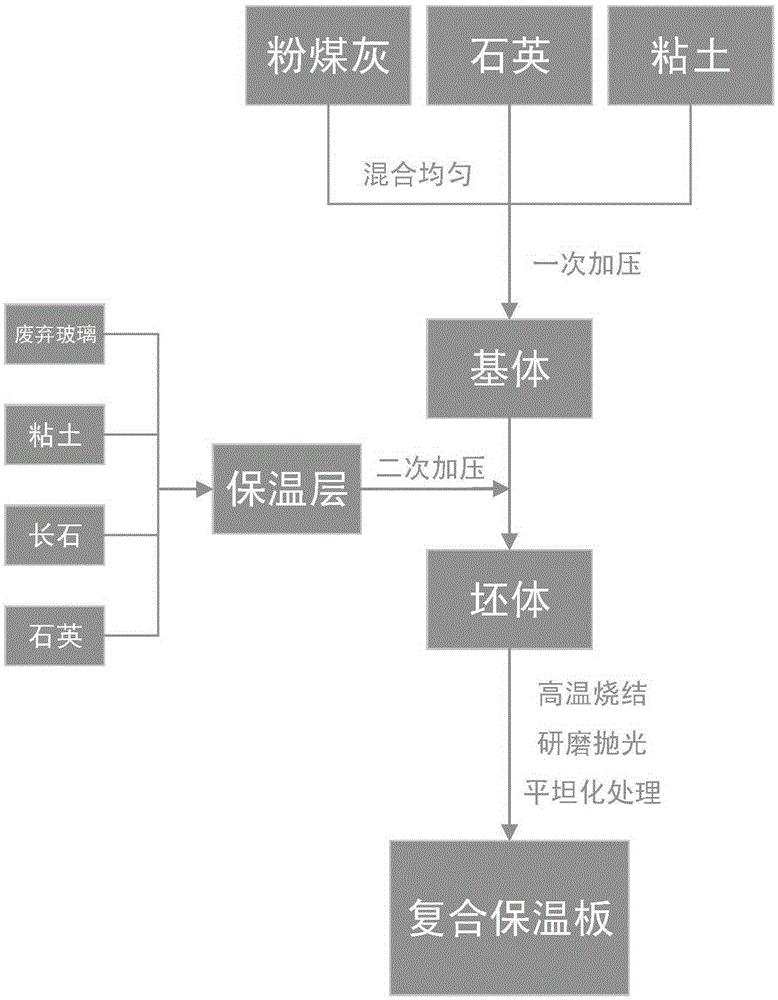

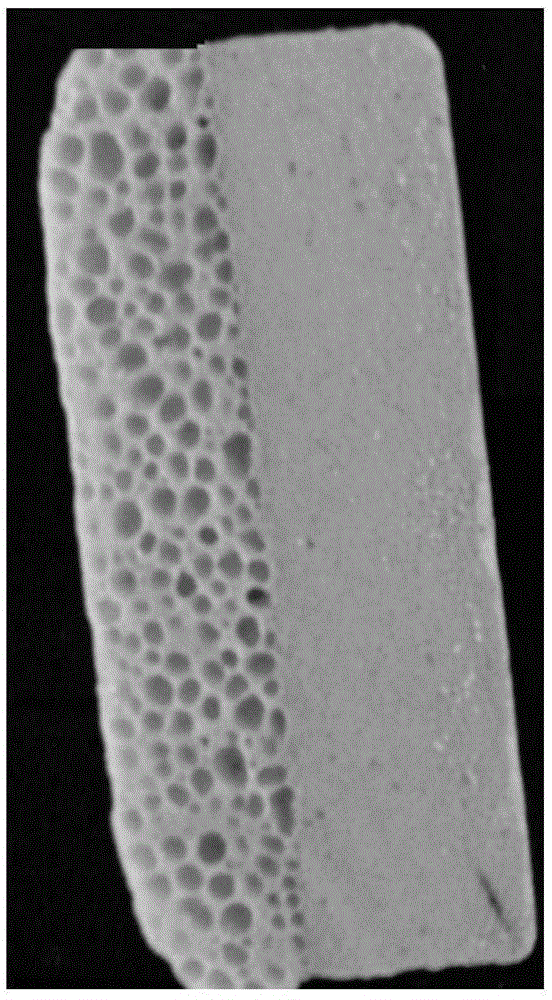

Composite heat-insulation board and preparation method thereof

ActiveCN105272158AImprove overall utilizationSolve UtilizationCeramic materials productionClaywaresInsulation layerResource utilization

The invention provides a novel composite heat-insulation board and its preparation method. Solid waste fly ash which is used as a main raw material undergoes one-time sintering to obtain the composite heat-insulation board. By the method for preparation of the composite heat-insulation board, the present situation of low comprehensive utilization rate of fly ash and environmental pollution is solved; and as a matrix layer and a heat-insulation layer both adopt the solid waste fly ash, costs of the composite heat-insulation board are greatly reduced, and added value of fly ash product utilization is raised. After one-step sintering, the matrix layer and the heat-insulation layer are greatly combined, and no binding material is needed. Thus, the matrix and the heat-insulation layer are sintered at a time to be integrated. According to the invention, resource utilization of garbage materials is realized, and field resources for fly ash landfill are minimized. The composite heat-insulation board meets requirements of energy conservation, waste utilization and environmental protection. In addition, the prepared composite heat-insulation board has high strength, good fireproof and heat-insulation properties, is resistant to water and insect pest, is conducive to popularization and application in practice and is of great economic, social and eco-environment protection significance.

Owner:PEKING UNIV

Double-reactor T-shaped nuclear power plant group integrally provided with low-intermediate-level waste disposal field

PendingCN110534220ASolve the problem of site selectionSave site resourcesNuclear energy generationNuclear power plant detailsNuclear engineeringNuclear power

The invention relates to the technical field of underground nuclear power plants, and discloses a double-reactor T-shaped nuclear power plant group integrally provided with a low-intermediate-level waste disposal field. The plant group comprises a disposal field, two reactor plant cavities and a combined plant cavity; the combined plant cavity comprises a safety plant, a fuel plant, a safety plantand a nuclear auxiliary plant which are sequentially arranged from outside to inside along the space of the underground cavity; the disposal field communicates with the nuclear auxiliary plant; eachof the reactor plant cavities is connected with an electric plant cavity and a pressure relief cavity; the reactor plant cavities, the electric plant cavities and the pressure relief cavity are all indouble-reactor T-shaped mirror arrangement with the axes of the combined plant cavity as a center; and the reactor plant cavities are both connected with fuel plant, the safety plants and the nuclearauxiliary plant. According to the double-reactor T-shaped nuclear power plant group integrally provided with the low-intermediate-level waste disposal field, the whole excavation amount of underground cavities is reduced, the problem of disposal of low-intermediate-level wastes after operation and decommissioning of nuclear power plants is solved, and whole economy is improved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

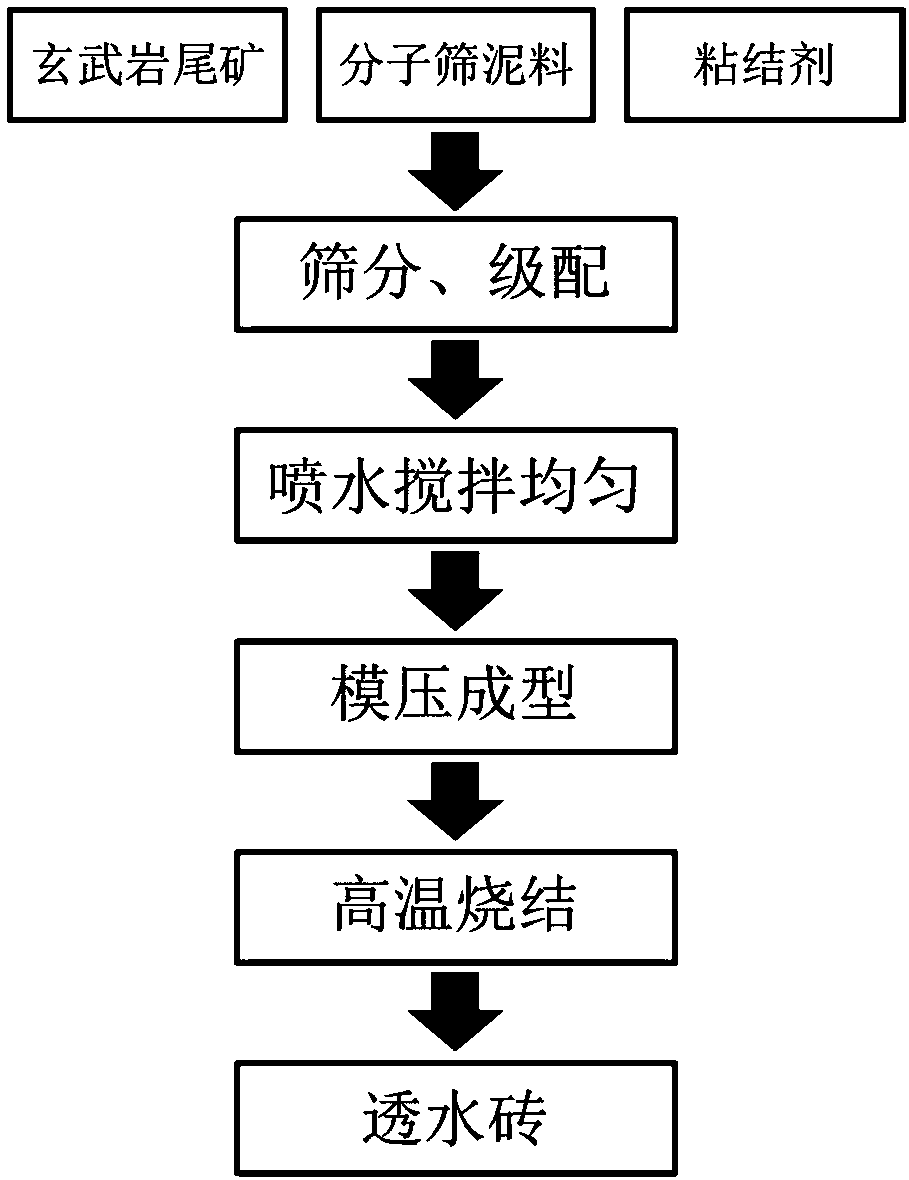

Water permeable brick prepared from basalt tailings and preparation method of water permeable brick

InactiveCN108358609AConvenient amountEasy to shapeSingle unit pavingsPaving gutters/kerbsMolecular sieveBrick

The invention relates to a water permeable brick prepared from basalt tailings. The water permeable brick comprises a surface layer and a bottom layer, wherein the surface layer is prepared from raw materials in parts by weight as follows: 85-95 parts of basalt tailing powder with particle size being 20-40 meshes, 2-8 parts of molecular sieve waste and 2-8 parts of clay; the bottom layer is prepared from raw materials in parts by weight as follows: 70-80 parts of basalt tailing powder with particle size being 5-20 meshes, 10-20 parts of the basalt tailing powder with particle size being 20-40meshes, 2-8 parts of the molecular sieve waste and 2-8 parts of the clay. According to the water permeable brick prepared from the basalt tailings, solid waste including the basalt tailings and the molecular sieve waste is taken as the raw materials, resource recycling of the solid waste is realized, and location resources occupied by landfill are reduced; the water permeable brick obtained by sintering has excellent properties, and the properties are better than indicators specified by national standards.

Owner:PEKING UNIV

A painting process for product coating

The invention discloses a painting process flow for product painting; a product on a feeding station is moved to a polishing chamber station by a power trolley for surface cleaning operation, the product is moved to a painting chamber station by the power trolley for painting operation according to requirements after completion, the product is moved to a drying chamber station by the power trolleyfor automatic drying according to paint drying requirements after completion, and the product is moved to a self-drying chamber station by the power trolley for drying after completion; after completion, the product is moved to a unloading buffer station or a unloading station by the power trolley to load and unload the product after painting is completed, and the power trolley returns to the loading station to cycle the next batch of products, and the cycle reciprocates accordingly. According to the invention, the problem of circulation among each working procedure of a workshop painting assembly line is solved, and the problem that the processing time of each working procedure is different is further solved, so that the assembly line can be circulated well.

Owner:SHANGHAI ZHENHUA PORT MACHINARY HEAVY IND CO LTD

A kind of permeable brick prepared from serpentine tailings and construction waste and preparation method thereof

ActiveCN110981396BIncrease added valueRealize recycling of resourcesSolid waste managementCeramic shaping apparatusBrickEnvironmental engineering

Owner:江苏未名环保科技有限公司

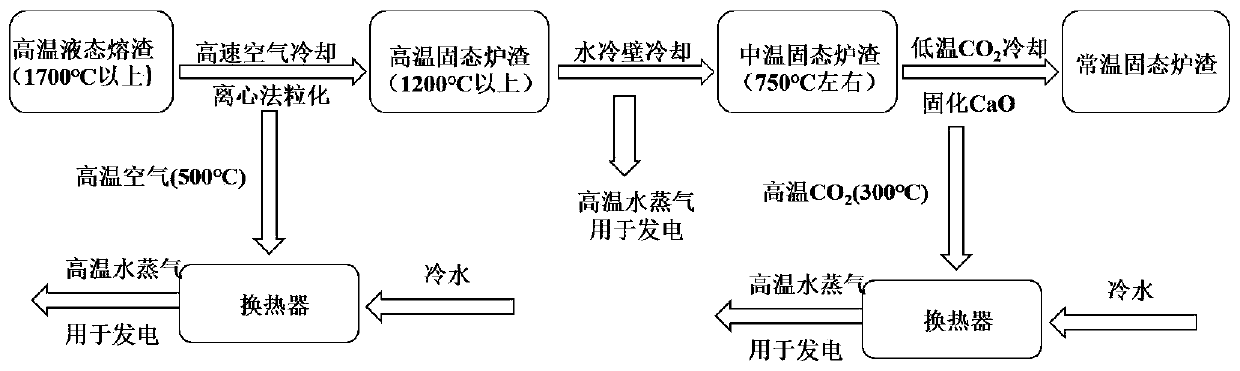

System and method for generating power with blast-furnace slag washing water and exhaust steam low-temperature waste heat

ActiveCN102787187BIncrease waste heat recoveryImprove efficiencyIncreasing energy efficiencyWaste heat treatmentSocial benefitsCooling tower

The invention discloses a system and a method for generating power with blast-furnace slag washing water and exhaust steam low-temperature waste heat. The system comprises a blast-furnace slag washing subsystem, a precipitation heat exchange subsystem and a low-temperature power generating subsystem, and exhaust steam and high-temperature slag washing water are separated from the slag washing water after slag washing of the blast-furnace slag washing subsystem, and then are delivered into the low-temperature power generating subsystem for generating power by the slag washing water after heat exchange of the heat exchange subsystem. Compared with the prior art, when recycling the blast-furnace slag washing water and the exhaust steam low-temperature waste heat, the system has the advantages that heat in the slag washing subsystem is comprehensively recycled so that the efficiency of the power generating subsystem is improved, cooling towers are dual-purpose, the number of the cooling towers is decreased, field resources are used, the blast-furnace slag washing water and the exhaust steam waste heat resources are recycled, energy is saved, emission is reduced, and fine economic and social benefits are achieved.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

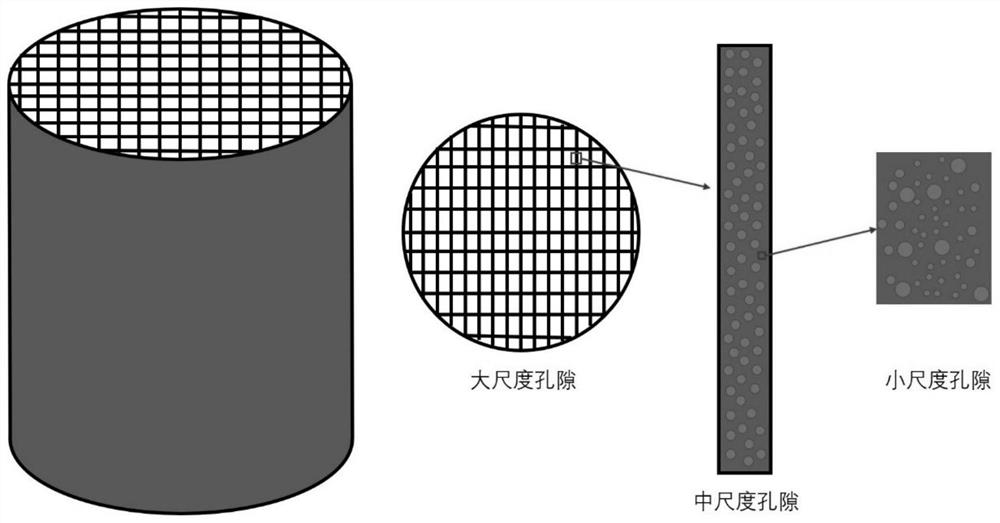

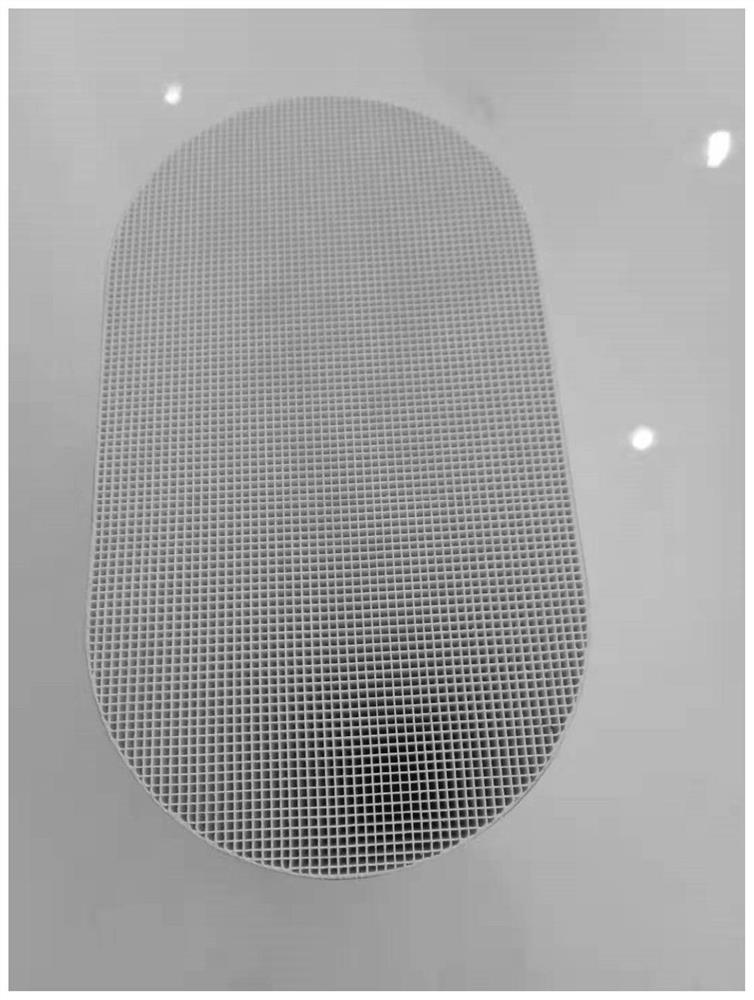

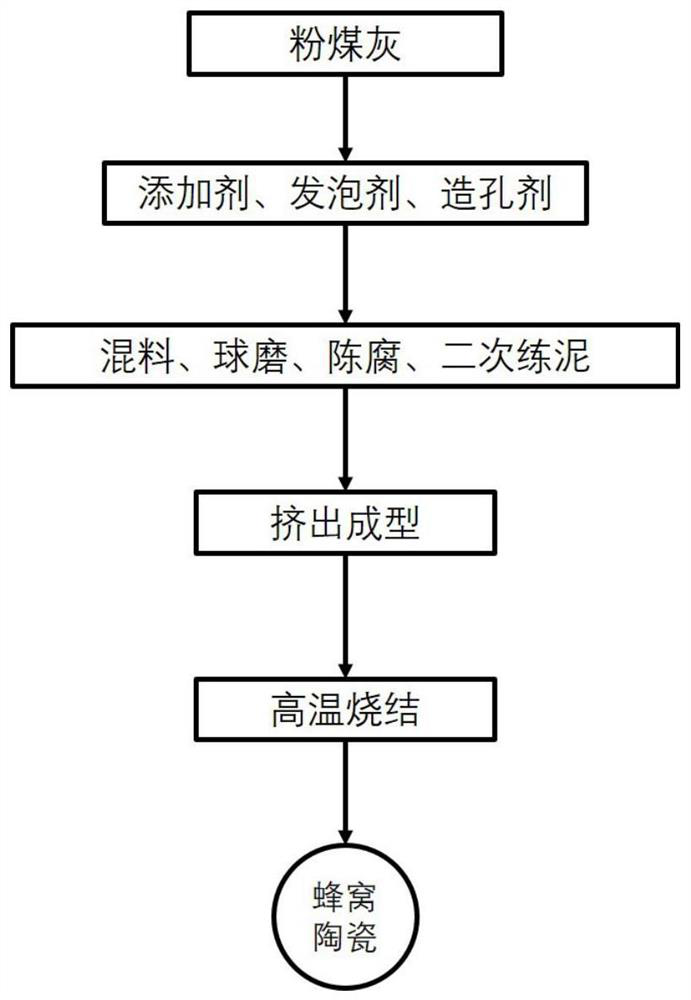

A kind of multi-scale porous honeycomb ceramic and its preparation method

ActiveCN111018560BLow raw material costTake advantage ofCeramic materials productionCeramicwareCarbide siliconNano silicon

The invention relates to the field of comprehensive utilization of solid waste resources and the field of preparation of inorganic non-metallic materials, and in particular, relates to a multi-scale pore honeycomb ceramic and a preparation method thereof. The multi-scale pore honeycomb ceramic comprises the raw materials: fly ash, an additive and a pore-preparing agent, wherein the pore-preparingagent is composed of a foaming agent and a pore-forming agent, the foaming agent is silicon carbide, and the pore-forming agent is nano silicon carbide. The preparation method of the multi-scale porehoneycomb ceramic comprises the steps: (1) mixing fly ash, an additive and the pore-preparing agent, and then carrying out ball milling, aging and secondary pugging to obtain pug; (2) carrying out extrusion molding on the pug through an extruder to prepare a honeycomb ceramic green body; and (3) drying the honeycomb ceramic green body, and sintering. According to the invention, the high-valued utilization of solid waste fly ash is realized, the additional value of the fly ash is increased, the manufacturing cost of the multi-scale porous honeycomb ceramic is reduced, and the performance of themulti-scale porous honeycomb ceramic is further improved.

Owner:PEKING UNIV

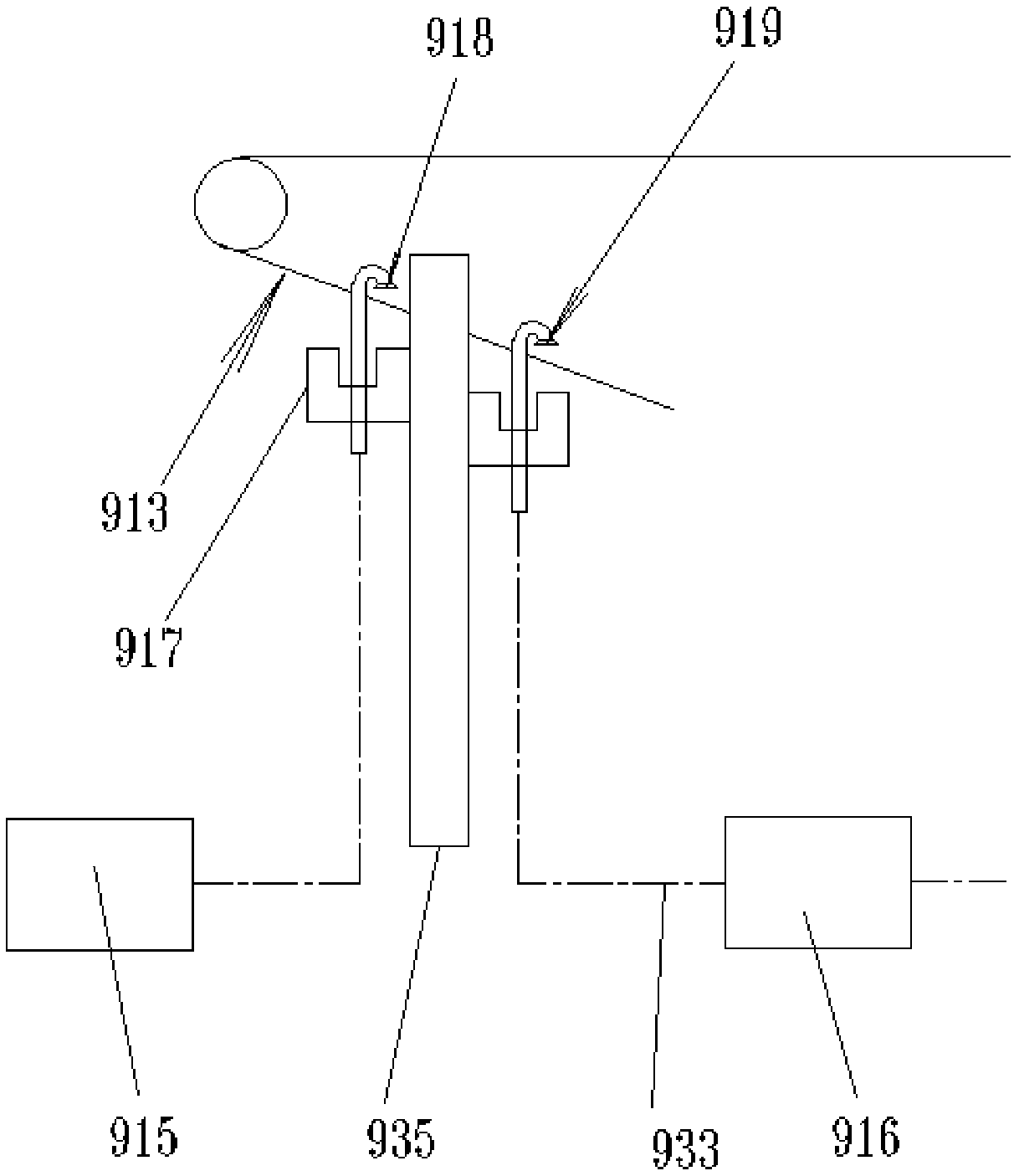

Method for hoisting, roasting and casting strip continuous casting flow distribution device

The invention discloses a method for hoisting, roasting and casting a strip continuous casting flow distribution device. The method comprises the following steps that: 1) the flow distribution device is arranged at two ends of the bottom of a tundish vehicle through a hanging mechanism, a distributor is arranged at the bottom of the tundish vehicle and inserted into the flow distribution device, and the tundish vehicle drives the flow distribution device and the distributor to move up and down; 2) during roasting, a roasting pit has an independent temperature control system, and gas nozzles are arranged on the periphery inside the roasting pit; 3) hot charging is performed after roasting is finished; and 4) after the tundish vehicle, the hanging mechanism and the flow distribution device reach a casting position, the hanging mechanism hangs the flow distribution device to descend together, and places the flow distribution device on a bracket of the flow distribution device of the roasting pit, and then the hanging mechanism is separated from the flow distribution device for molten steel to inject. By the method, the time of strip continuous casting hot charging process can be effectively reduced, so that temperature drop of the flow distribution device in the process of hot charging is reduced, the problem that cold steel is easy to form when the high-temperature molten steel is contacted with the flow distribution device can be effectively avoided, and the success rate of strip continuous casting pouring is improved; the method is convenient to operate and the hot charging step is convenient to implement at the same time; and a heating furnace can also be saved and field resources are greatly saved.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com