Light foaming imitation wood floor and preparation method thereof

A wood-like floor and foaming agent technology, which is applied in the field of foamed wood-like floors, can solve the problems of unfavorable market promotion and high self-weight of wood-like floor boards, and achieve the effects of reducing site resources, saving manpower and material resources, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment relates to a wood-like floor, comprising the following raw materials in parts by weight:

[0035] 40 parts of fly ash, 30 parts of PVC, 12 parts of light calcium carbonate, 4 parts of paraffin, 1 part of AC foaming agent, 6 parts of dioctyl phthalate, 1 part of stearic acid, compound stabilizer (polyamino modified Silicone oil and barium stearate, polyamino modified silicone oil 60%) 6 parts.

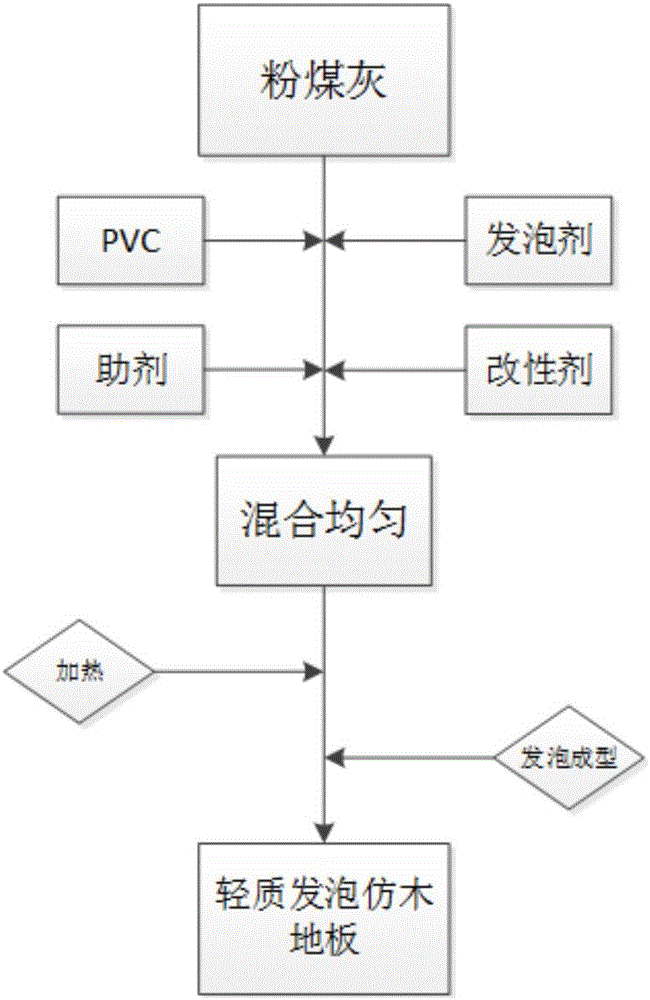

[0036] The present embodiment also provides the preparation method of above-mentioned imitation wood floor, comprises the steps:

[0037] 1) Stir each raw material evenly;

[0038] 2) Put the uniformly mixed materials into the floor molding machine and extrude after foaming at a high temperature of 185°C to make a light imitation wood foam floor substrate board.

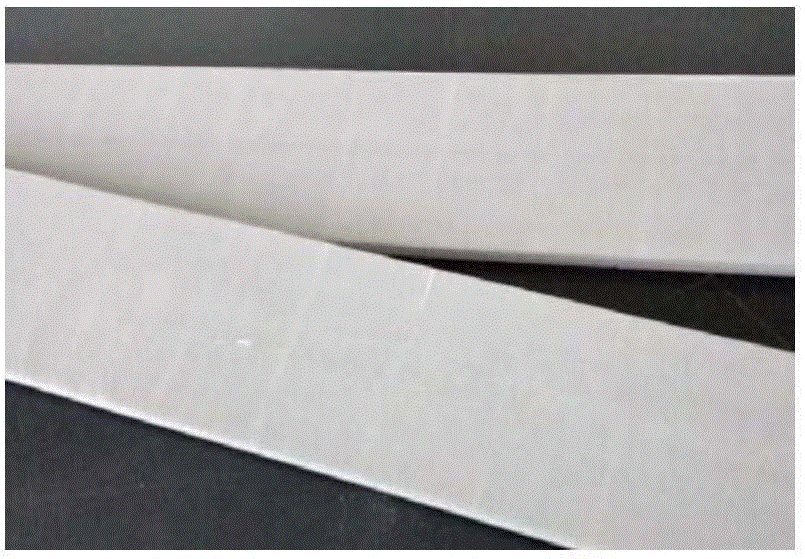

[0039] 3) The obtained floor substrate boards are sequentially cut, four layers of surface treatment, testing, and packaging to obtain finished products. The appearance of the obtained product is as ...

Embodiment 2

[0041] This embodiment relates to a wood-like floor, comprising the following raw materials in parts by weight:

[0042] 50 parts of fly ash, 20 parts of PVC, 12 parts of light calcium carbonate, 4 parts of paraffin, 1 part of AC foaming agent, 6 parts of dioctyl phthalate, 1 part of stearic acid, compound stabilizer (polyamino modified Silicone oil and barium stearate, polyamino modified silicone oil 60%) 6 parts.

[0043] The present embodiment also provides the preparation method of above-mentioned imitation wood floor, comprises the steps:

[0044] 1) Stir each raw material evenly;

[0045] 2) Put the uniformly mixed materials into the floor molding machine and extrude after foaming at a high temperature of 200°C to make a light imitation wood foam floor substrate board.

[0046] 3) The obtained floor substrate boards are sequentially cut, four layers of surface treatment, testing, and packaging to obtain finished products.

Embodiment 3

[0048] This embodiment relates to a wood-like floor, comprising the following raw materials in parts by weight:

[0049] 45 parts of fly ash, 25 parts of PVC, 15 parts of light calcium carbonate, 2 parts of paraffin, 1.5 parts of AC foaming agent, 5 parts of dioctyl phthalate, 0.5 part of stearic acid, compound stabilizer (polyamino modified Silicone oil and barium stearate, polyamino modified silicone oil 50%) 7 parts.

[0050] The present embodiment also provides the preparation method of above-mentioned imitation wood floor, comprises the steps:

[0051] 1) Stir each raw material evenly;

[0052] 2) Put the uniformly mixed materials into the floor molding machine and extrude after foaming at a high temperature of 190°C to make a light imitation wood foam floor substrate board.

[0053] 3) The obtained floor substrate boards are sequentially cut, four layers of surface treatment, testing, and packaging to obtain finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com