A painting process for product coating

A process and product technology, applied in spray booths, spray devices, etc., can solve problems such as different processing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

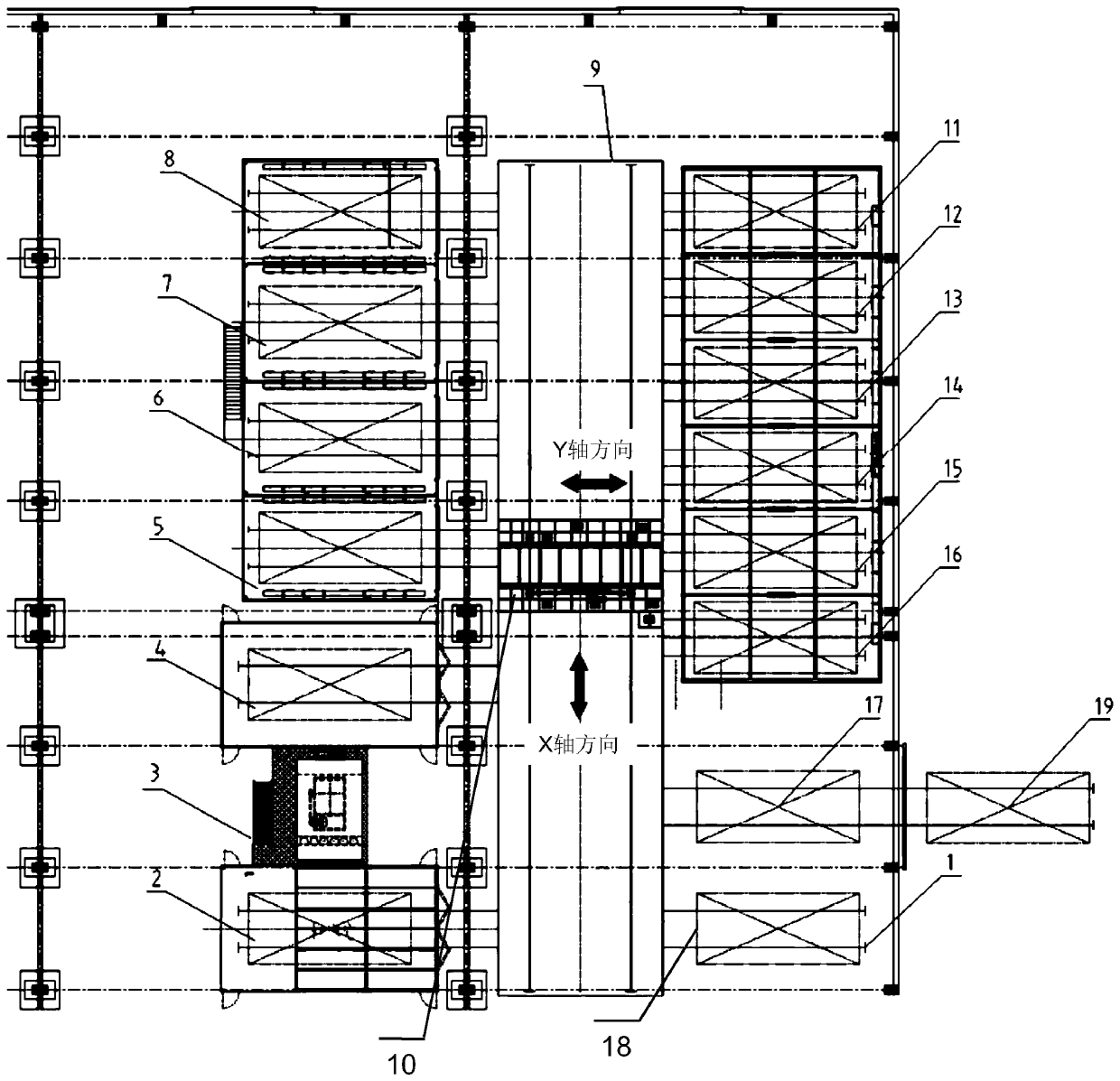

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

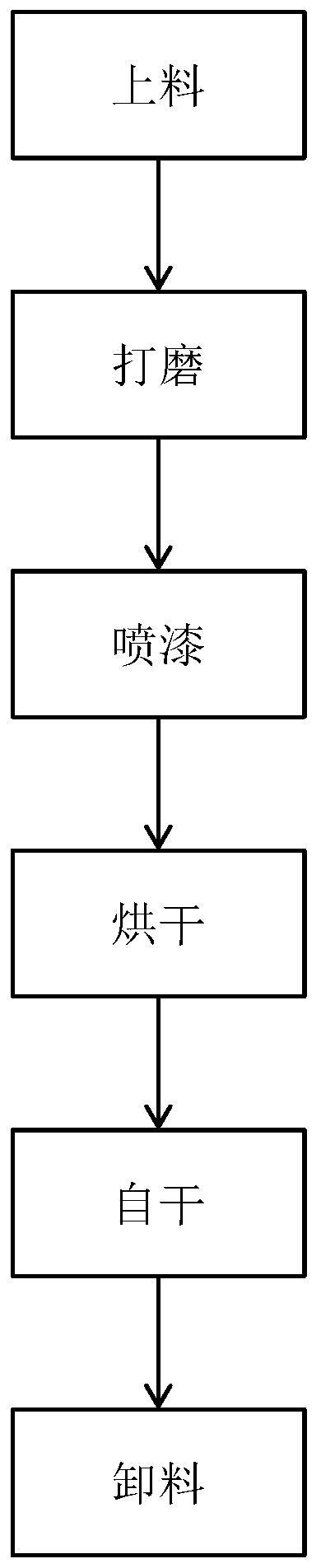

[0025] Please combine Figure 1 to Figure 2 Shown, a kind of product coating process flow of painting provided by the present invention:

[0026] First lay the power trolley track 9, and set corresponding stations along the two sides of the power trolley track 9X axis direction, specifically:

[0027] Along one side of the 9X-axis direction of the power trolley track, a grinding room station 2, a paint spraying room station 3 and four drying room stations (drying room station one 5, drying room station two 6 , drying room station three 7, drying room station four 8). Along the other side of the power trolley track 9X axis direction, a loading station 1, a discharge buffer station 17 and six self-drying room stations (self-drying room station-11, self-drying room station Two 12, self-drying room station three 13, self-drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com