Iron tailing ceramsite and preparation method thereof

A technology of iron tailings and ceramsite, which is applied in the field of iron tailings ceramsite and its preparation, can solve the problems of polluting the environment and occupying land, and achieve the effects of increasing added value, promoting further increase, and increasing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with specific embodiments.

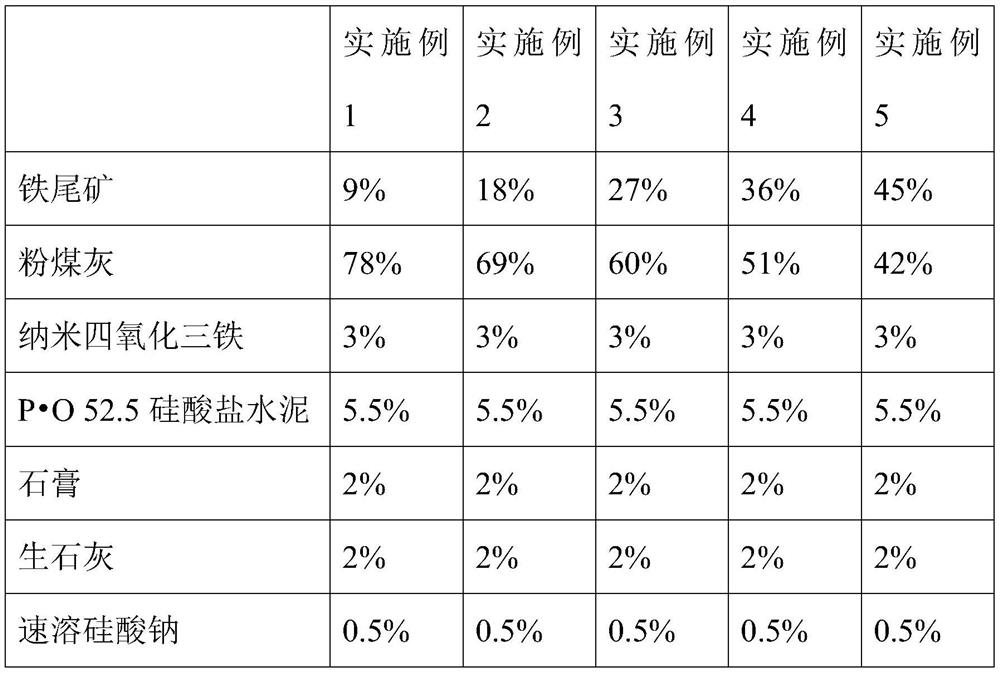

[0029] The used raw material composition of embodiment 1-5 is as shown in the table below:

[0030]

[0031] The iron tailings ceramsite preparation method of embodiment 1-5 comprises the steps:

[0032] S1, passing the dried iron tailings through a 0.6mm square hole sieve to obtain fine iron tailings;

[0033] S2. Mix the iron tailings fine material with fly ash, gypsum, quicklime, instant sodium silicate, and magnetic nanomaterials to obtain a powdery material; add 270g of water to each kilogram of the powdery material and stir to obtain a mixed material;

[0034] S3. Put the mixed material into a disc pelletizer to make pellets, the pelletizing time is 10 minutes, place for 12 hours, and dry at 105°C for 6-8 hours to obtain spherical ceramsite;

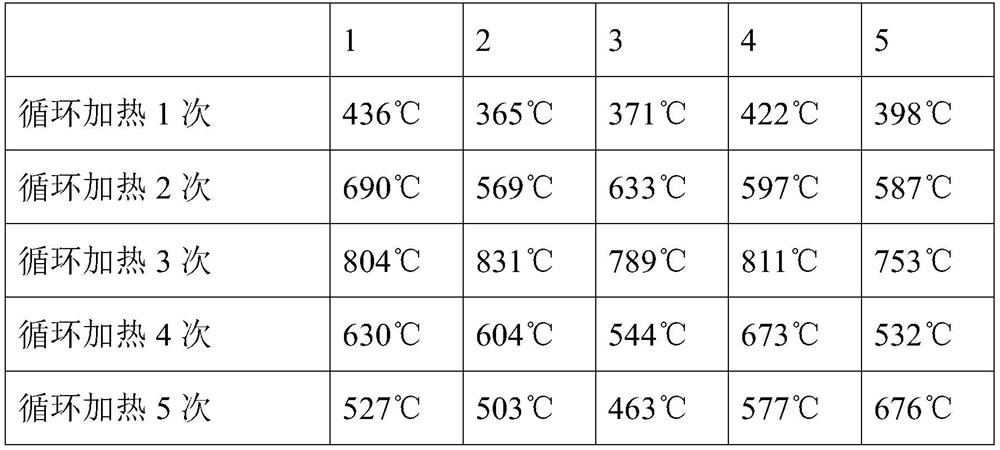

[0035] S4. Cool the spherical ceramsite to room temperature, and then put it into an industrial microwave oven for microw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com