A kind of multi-scale porous honeycomb ceramic and its preparation method

A honeycomb ceramic, multi-scale technology, applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of high preparation cost, limited practical application, shortage of raw materials, etc., to increase added value, reduce site resources, reduce The effect of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

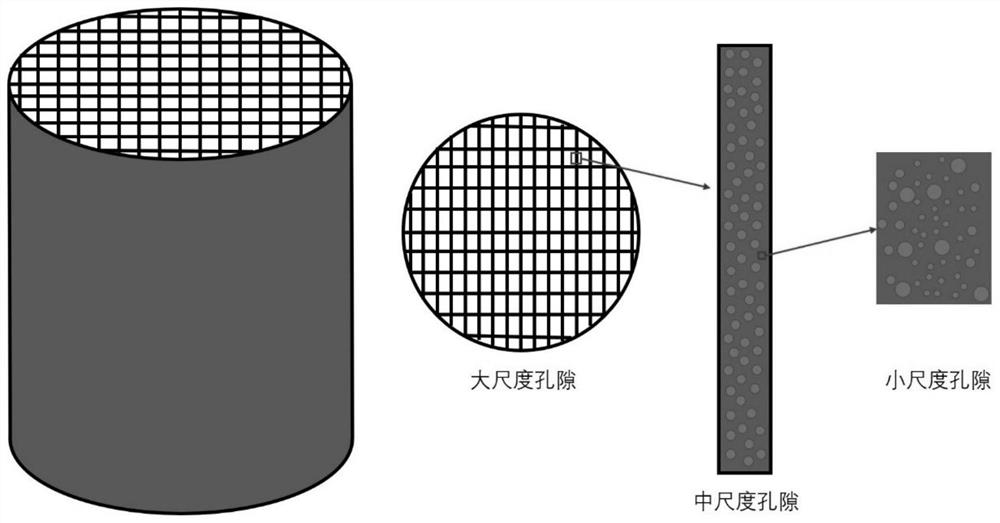

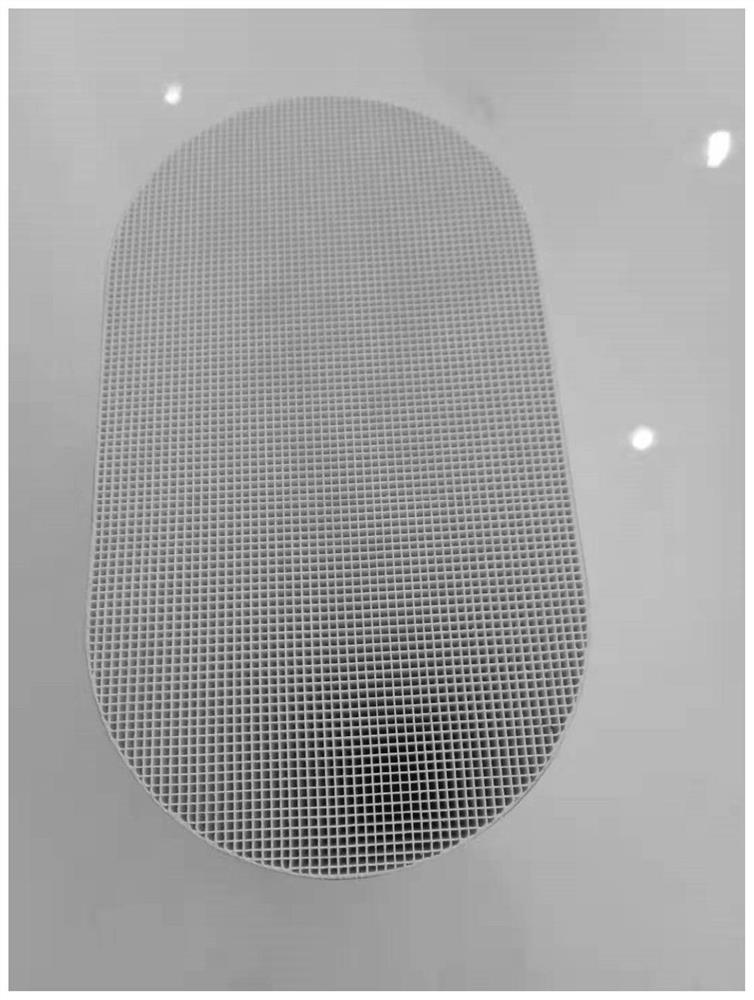

[0042] This embodiment provides a kind of multi-scale porous honeycomb ceramics (such as figure 1 with 2 ), based on the gross weight of the multi-scale porous honeycomb ceramics, the raw material consists of the following percentage components:

[0043]

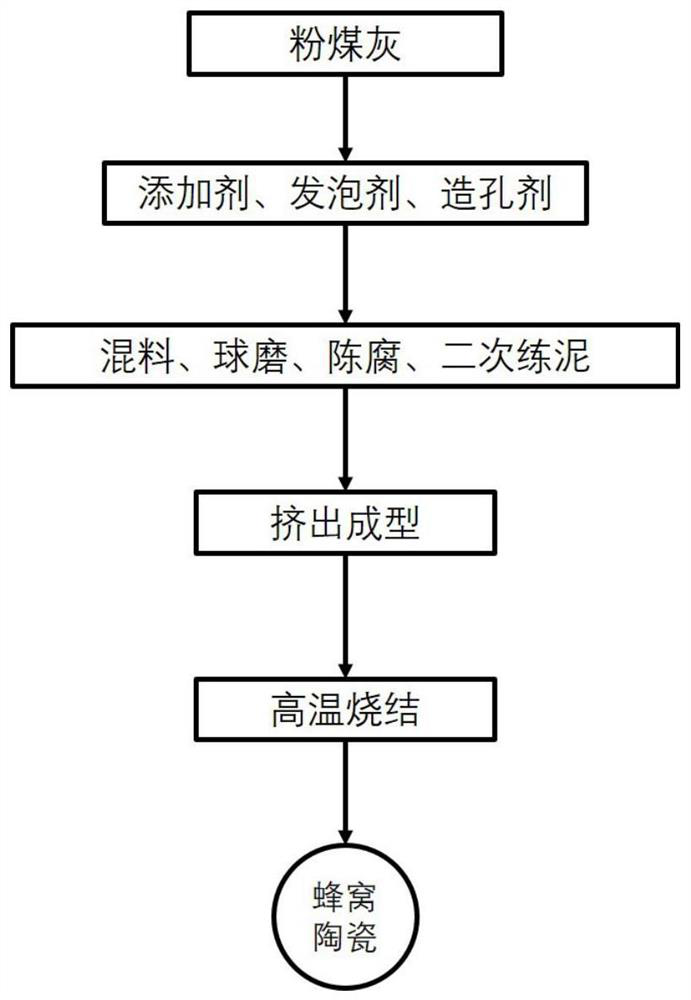

[0044] The preparation method of described multi-scale porous honeycomb ceramics is as follows (as image 3 ):

[0045] (1) After mixing fly ash, clay, feldspar, magnesite, silicon carbide, and nano-silicon carbide, ball mill, stale, and secondary mud refining to obtain mud;

[0046] (2) extruding the mud material through an extruder at 8Mpa to obtain a honeycomb ceramic green body;

[0047] (3) The honeycomb ceramic green body is subjected to continuous microwave drying in a tunnel microwave oven, and sintered at 1100° C. for 4 hours.

Embodiment 2

[0049] This embodiment provides a kind of multi-scale porous honeycomb ceramics (such as Figure 4 , 5 , 6), based on the total weight of the multi-scale porous honeycomb ceramics, the raw material is composed of the following percentage components:

[0050]

[0051] The preparation method of the multi-scale porous honeycomb ceramics is the same as that in Example 1.

[0052] The preparation method of described multi-scale porous honeycomb ceramics is as follows (as image 3 ):

[0053] (1) After mixing fly ash, clay, feldspar, magnesite, silicon carbide, and nano-silicon carbide, ball mill, stale, and secondary mud refining to obtain mud;

[0054] (2) extruding the mud material through an extruder at 10Mpa to obtain a honeycomb ceramic green body;

[0055] (3) The honeycomb ceramic green body is subjected to continuous microwave drying in a tunnel microwave oven, and sintered at 1200° C. for 3 hours.

Embodiment 3

[0057] This embodiment provides a multi-scale porous honeycomb ceramic, based on the total weight of the multi-scale porous honeycomb ceramic, the raw material is composed of the following percentage components:

[0058]

[0059]The preparation method of the multi-scale porous honeycomb ceramics is the same as that in Example 1.

[0060] The preparation method of described multi-scale porous honeycomb ceramics is as follows (as image 3 ):

[0061] (1) After mixing fly ash, clay, feldspar, magnesite, silicon carbide, and nano-silicon carbide, ball mill, stale, and secondary mud refining to obtain mud;

[0062] (2) extruding the mud material through an extruder at 12Mpa to obtain a honeycomb ceramic green body;

[0063] (3) The honeycomb ceramic green body is subjected to continuous microwave drying in a tunnel microwave oven, and sintered at 1300° C. for 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com