Efficient multi-station casting machine and casting method thereof

A multi-station and casting machine technology, applied in the field of low-pressure casting, can solve the problems of low utilization rate of multi-station casting machines, achieve the effects of improving efficiency, reducing emissions, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

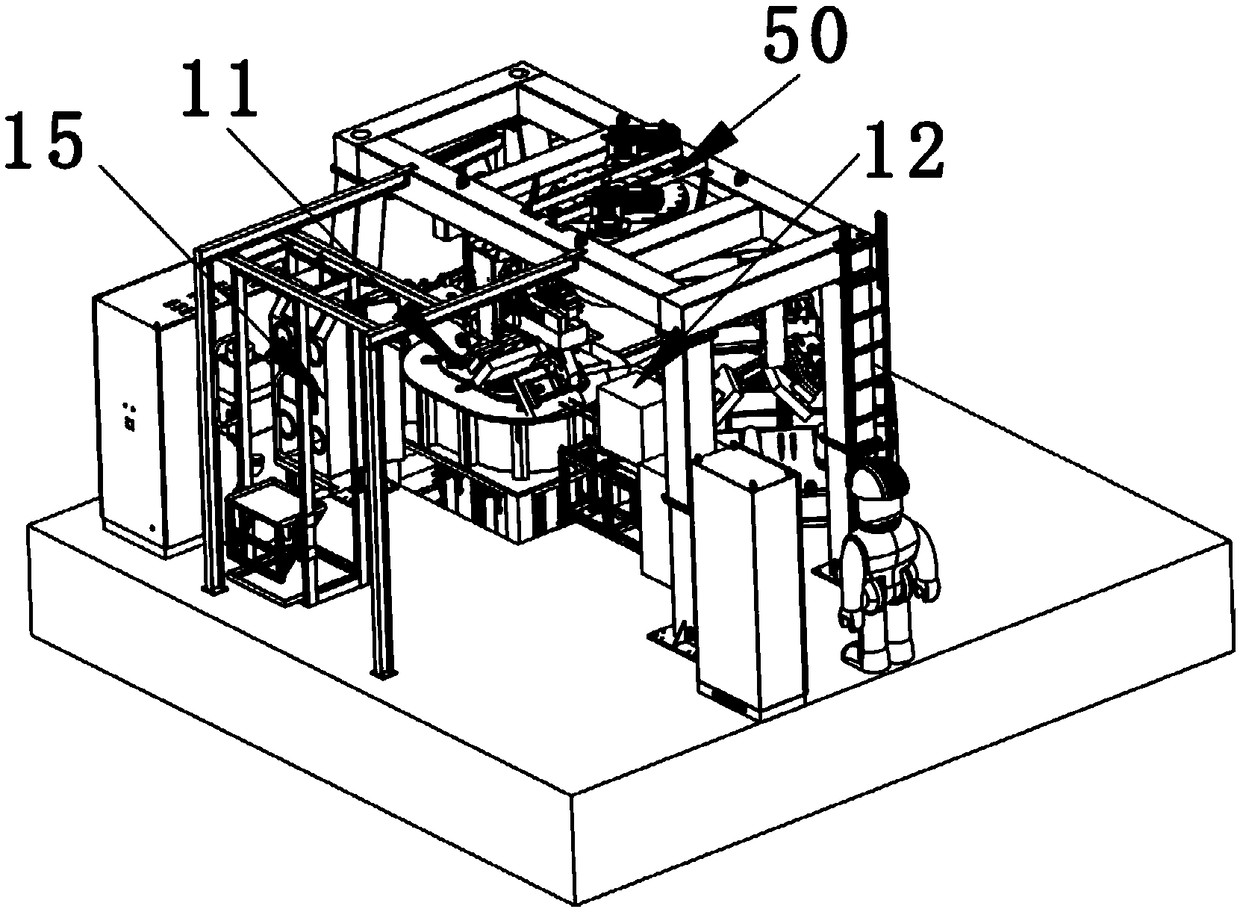

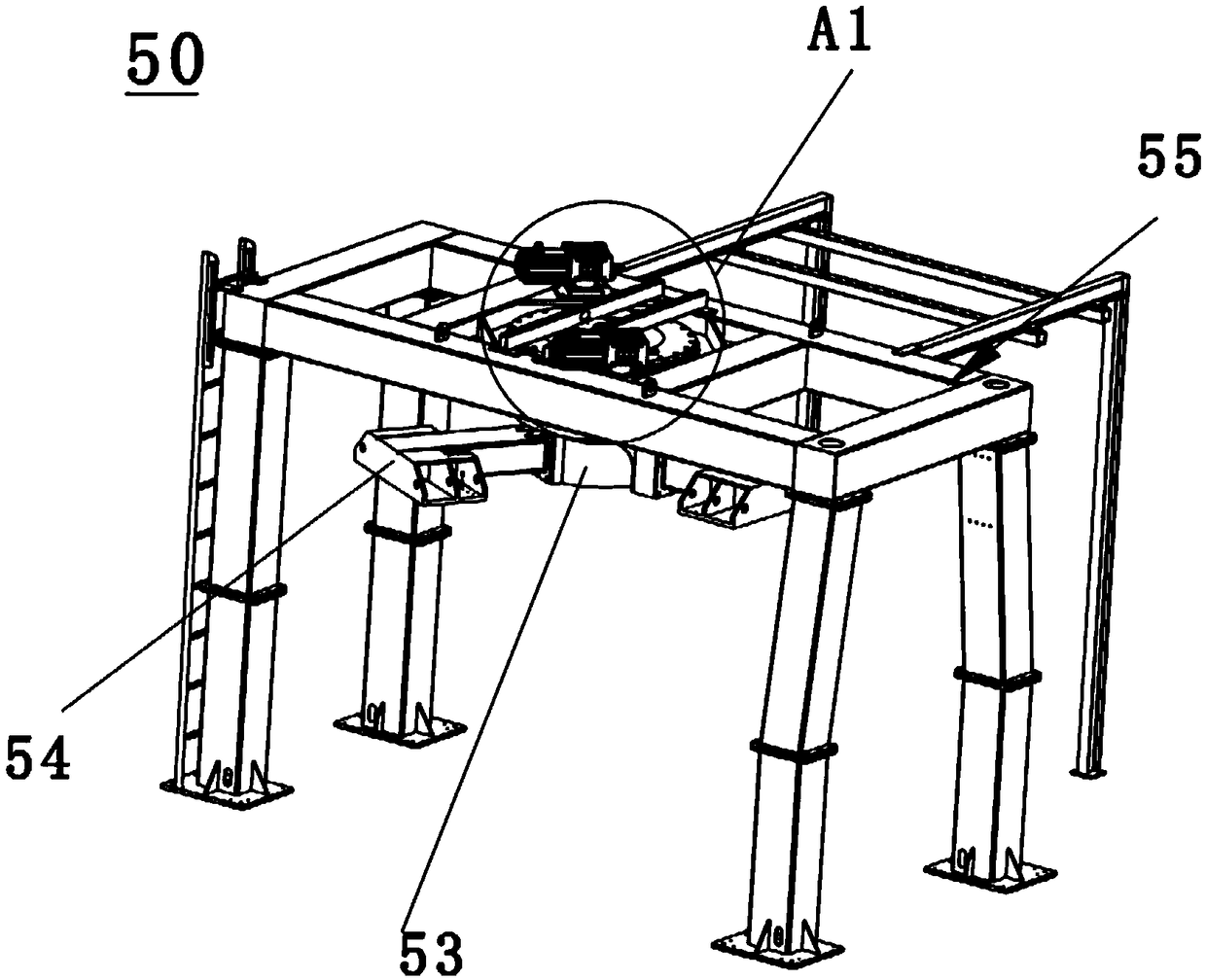

[0050] Please refer to Figure 1 to Figure 7 . A high-efficiency multi-station casting machine, comprising: a first station 11 for filling sand cores into an injection mold, a second station 12 for injecting hot-melt materials into the injection mold, and a A third station 13 for forming the casting, a fourth station 14 for soaking the mould, and a manipulator 20 .

[0051] The manipulator 20 can drive the injection mold through the first station 11, the second station 12, the third station 13 and the fourth station 14, and control the corresponding action of the injection mold when the injection mold moves to the corresponding station so as to Complete the corresponding casting steps. For example, the manipulator 20 cooperates with the first station 11 to perform the operation of placing the sand core, and cooperates with the second station 12 to complete the filling operation; cooperates with the third station 13 to complete the blanking operation of the components , coop...

Embodiment 2

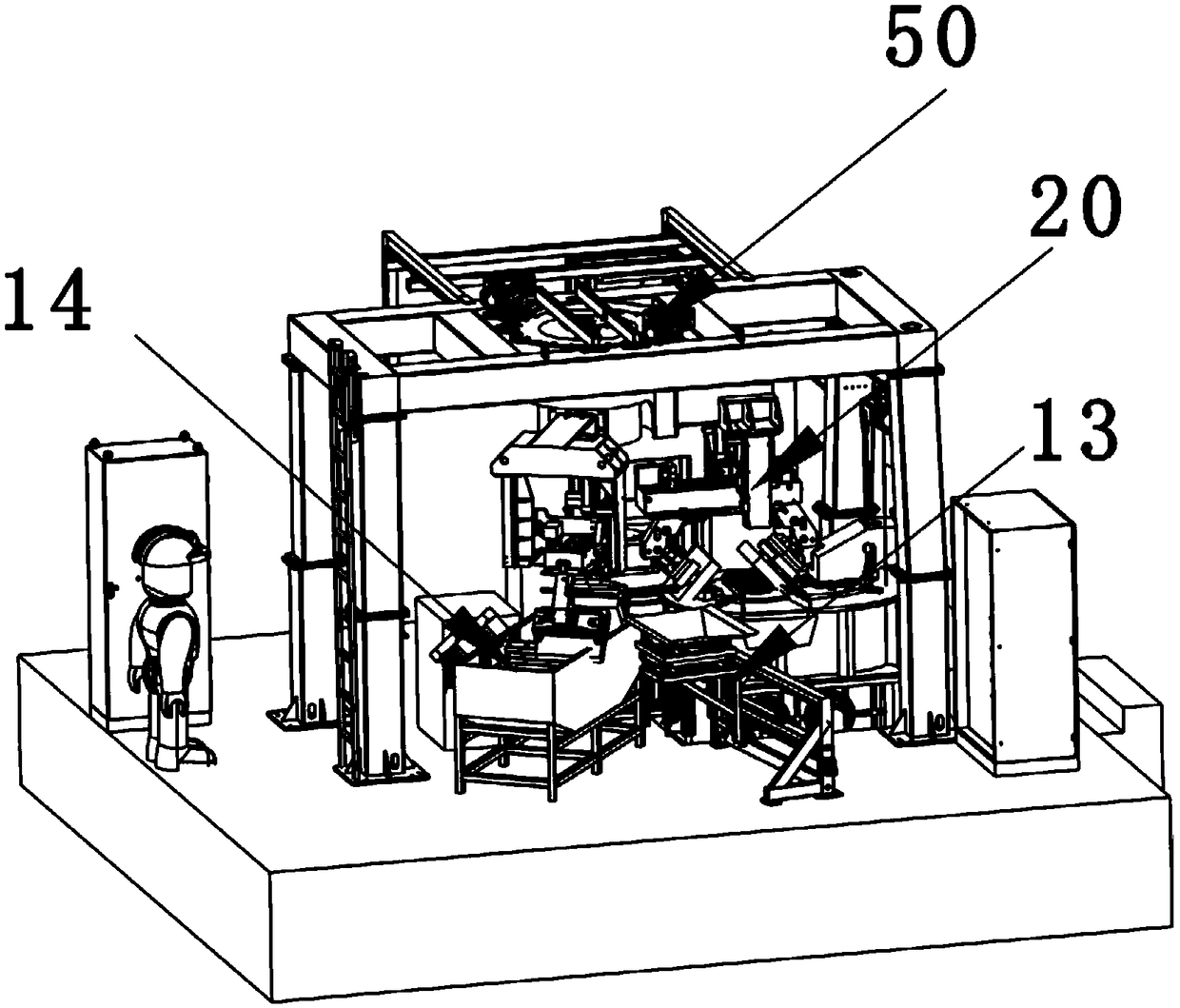

[0077] Please refer to Figure 8 to Figure 9 . The implementation principles and technical effects of the device provided by the embodiment of the present invention are basically the same as those in Embodiment 1. For a brief description, for details not mentioned in this embodiment, reference may be made to the corresponding content in Embodiment 1.

[0078] In this embodiment, the first station 11, the second station 12, the third station 13 and the fourth station 14 are evenly arranged around the axis of the rotating disc 51 , there are three manipulators 20, corresponding to the first station 11, the third station 13, and the fourth station 14 in the initial state, and each time the rotating mechanism 50 rotates, the three Manipulator 20 all corresponds to one of above-mentioned each station respectively.

[0079] Therefore, the difference from embodiment 1 is that each production cycle of embodiment 1 can produce 4 molded castings, and this embodiment can produce 3 cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com