Turning conveying track adapting to rapid heating steel billet manufacturing

A transmission track and rapid heating technology, which is applied in the field of round steel processing, can solve the problems that round steel cannot realize automatic turning and reversing, serious waste of site resources, and limited space, so as to reduce the required length of the workshop and reduce the occupied area. Large area, flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

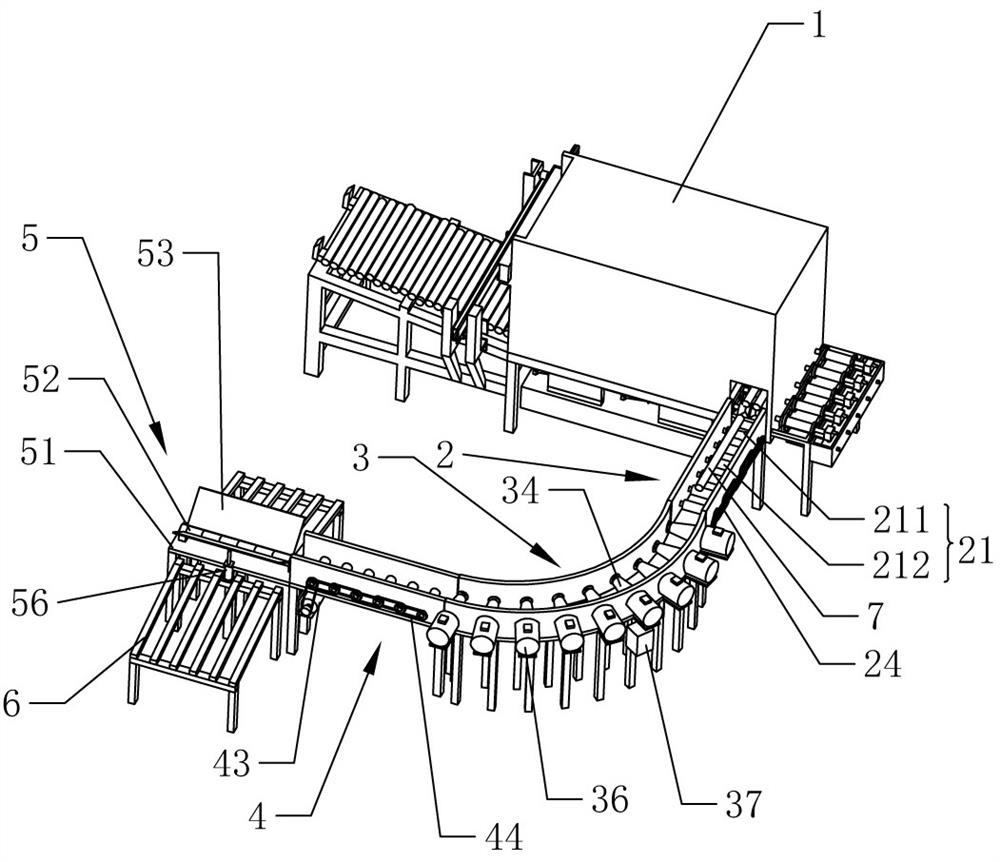

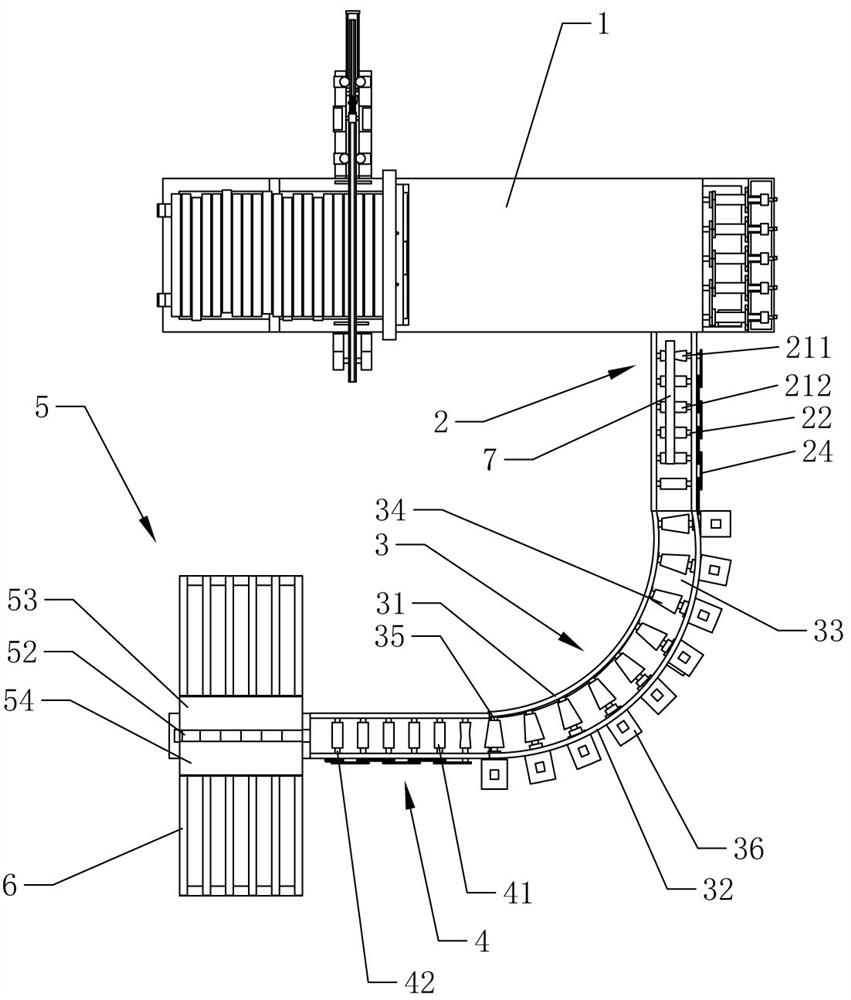

[0032] A turning transmission track suitable for rapid heating billets, such as figure 1 and figure 2 As shown, a walking furnace 1 is included, and the discharge port of the walking furnace 1 is connected with a front straight track 2, an arc-shaped transmission track 3 and a rear straight track 4 in sequence, and a shunt assembly 5 is arranged at the exit of the rear straight track 4. After the round steel 7 heated at high temperature in the walking furnace 1 is sent out from the discharge port, it is transported successively through the front straight track 2, the arc-shaped transmission track 3 and the back straight track 4, and finally the round steel 7 is sequentially carried out in the shunt assembly 5. Divide flow to realize double-track synchronous processing.

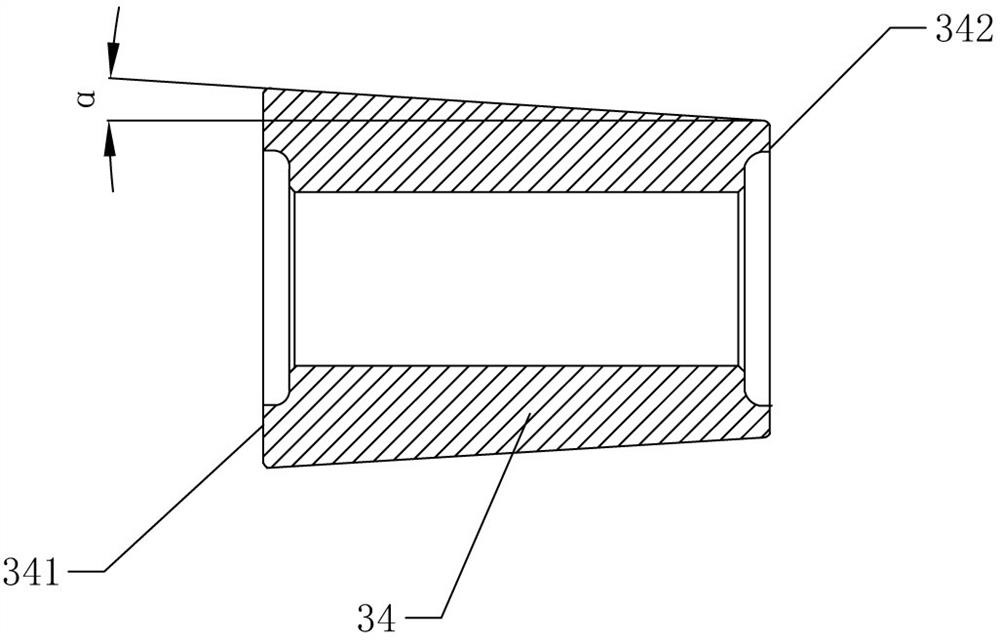

[0033] Such as figure 1 , figure 2 and Figure 5As shown, several front rollers 21 are seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com