Rotary kiln with material turning function

A technology of rotary kiln and material turning, applied in the field of rotary kiln, can solve the problems such as the inability to turn the material inside the hazardous waste stack to the outside, the hazardous waste cannot be heated evenly, and the degree of tumbling is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them.

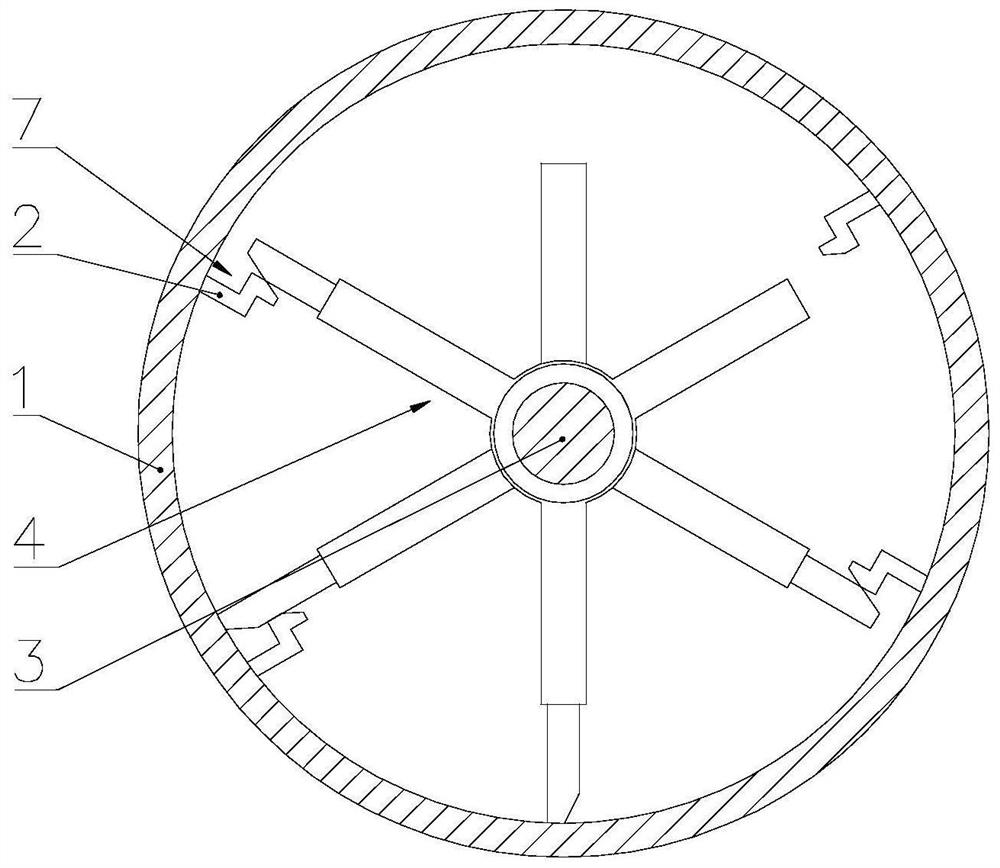

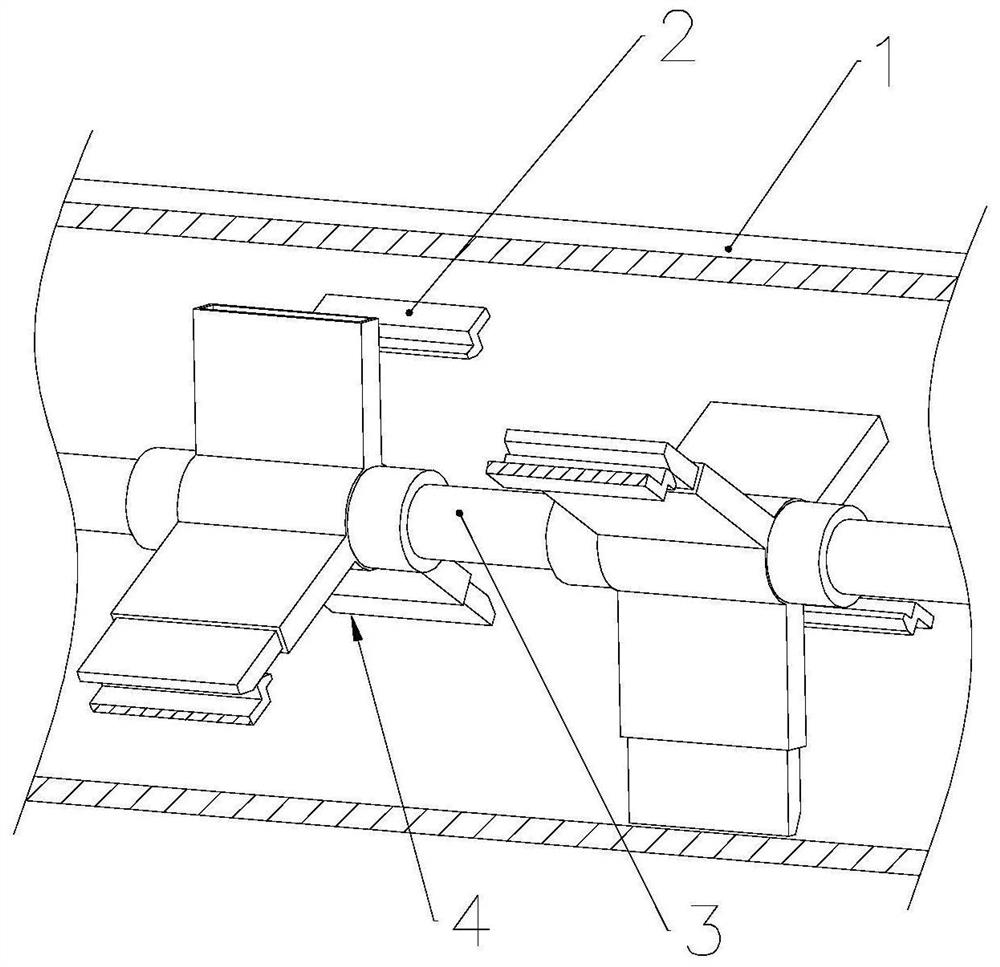

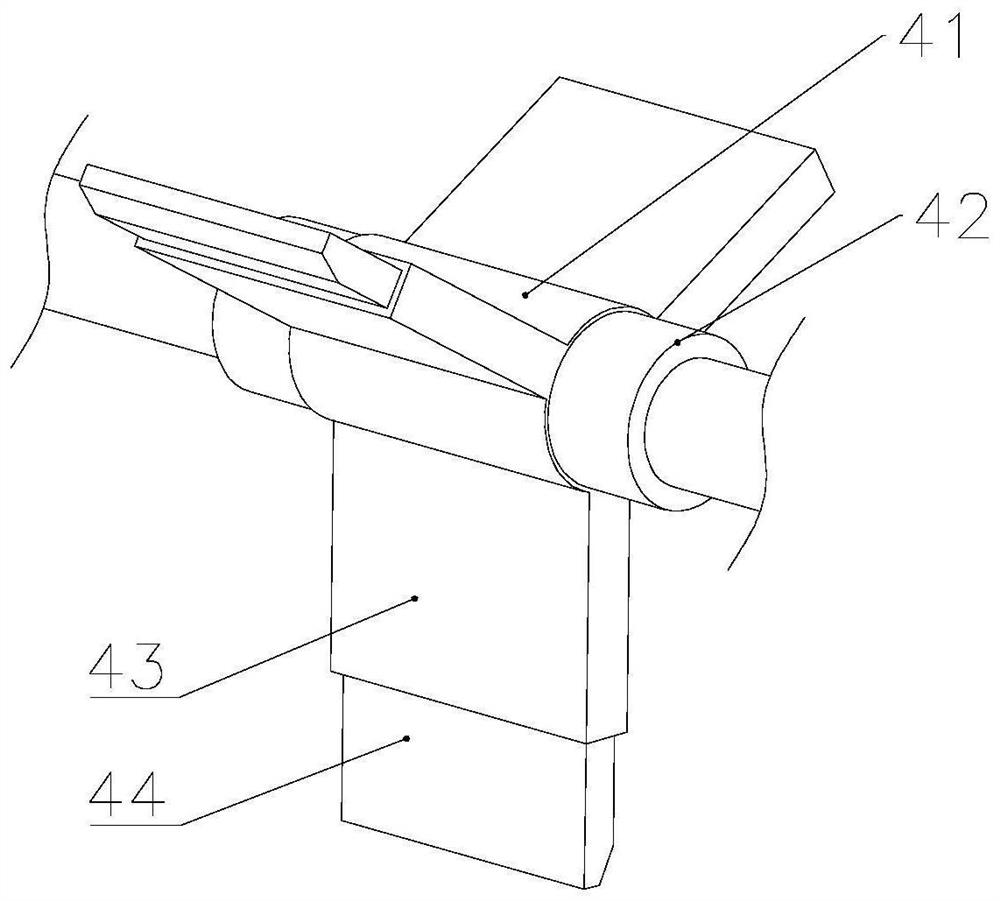

[0032] Such as Figure 1-10As shown, a rotary kiln with a material turning function includes: a kiln head, a drum 1 and a kiln tail. The drum 1 is obliquely arranged on the kiln head and the kiln tail. There is a linkage 2 on it, and the linkage 2 is used to drive the material turning mechanism 4 to carry out the material turning operation. The material turning mechanism 4 includes a rotating ring sleeve 41 and two limit slides 42, and the rotating ring sleeve 41 is provided with three equiangular angles. The provided telescopic frame body 43 is provided with a telescopic baffle plate 44 that slides and fits therein. After the telescopic baffle plate 44 stretches out, it can abut and cooperate with the linkage 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com