Hardware perforating device

A punching device and hardware technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low punching efficiency, complicated fixing process, hardware punching error, etc., and achieve faster punching speed. , The punching position is accurate, the effect of good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

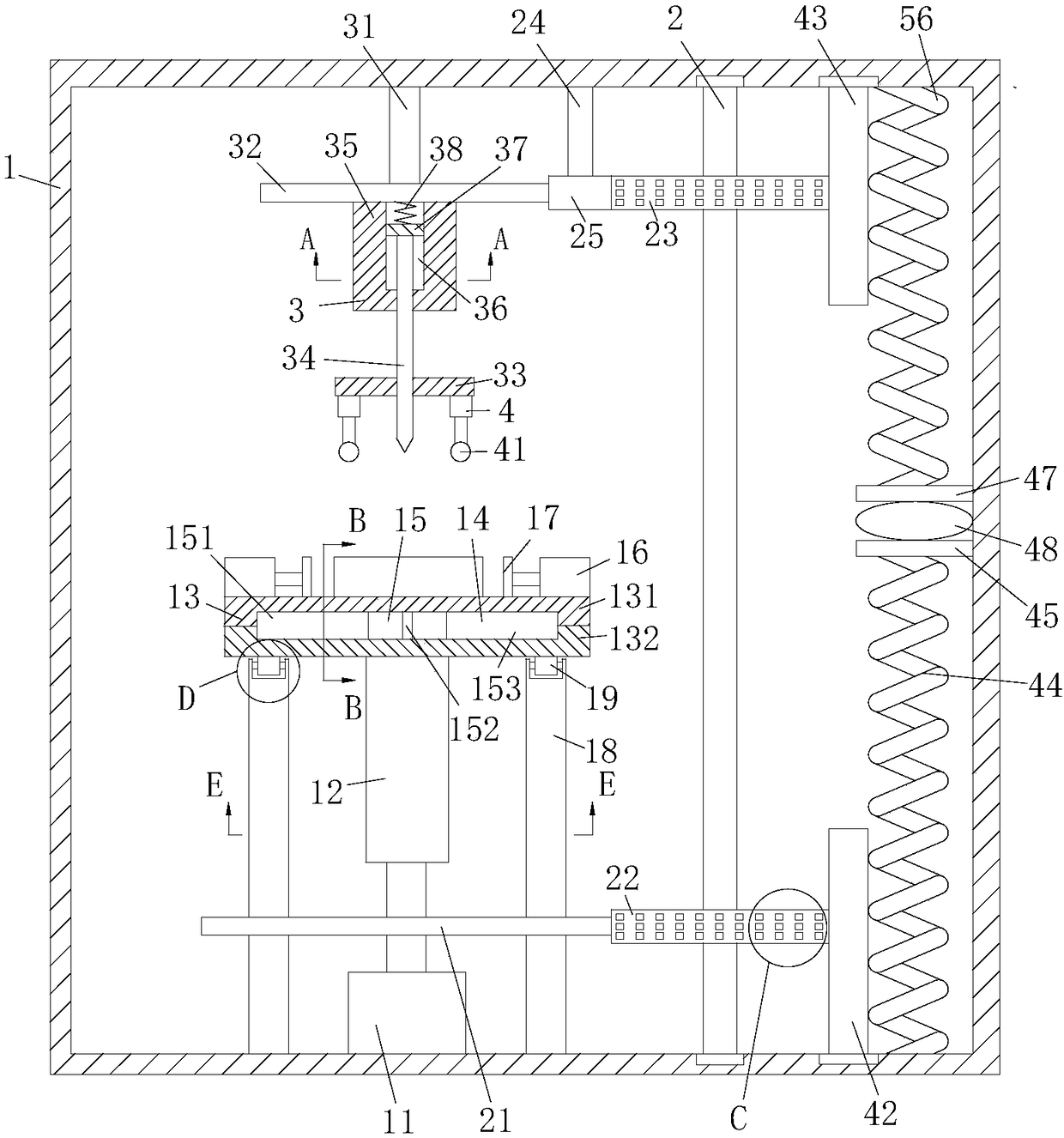

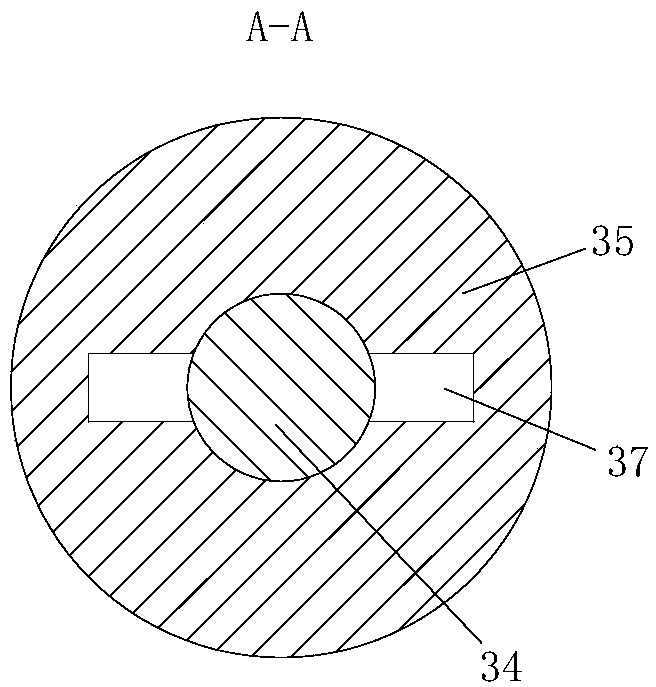

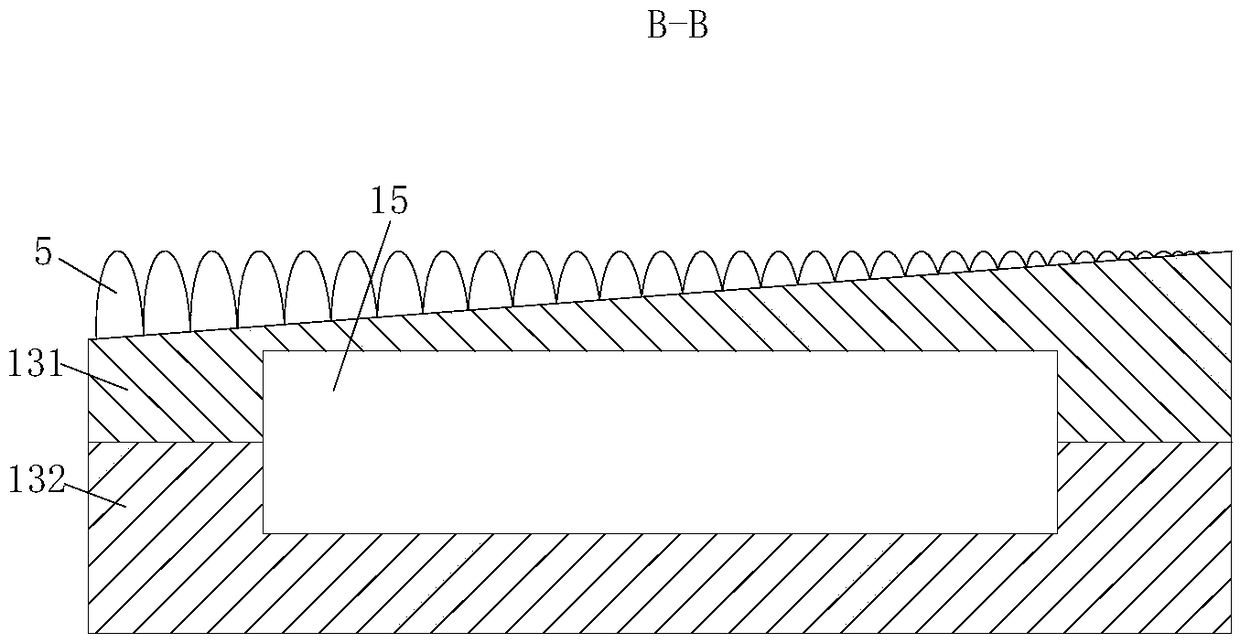

[0026] As an embodiment of the present invention, the punching unit 3 includes a third fixed rod 31, a fifth gear 32, a fixed plate 33 and a drill rod 34; one end of the third fixed rod 31 is fixedly connected to the top of the frame body 1. On the inner wall, the other end is rotatably connected with a fifth gear 32; the fifth gear 32 meshes with the fourth gear 25; the lower surface of the fifth gear 32 is fixedly connected with a rotating block 35; the rotating block 35 defines a limit Groove 36; a drill rod 34 is provided under the rotating block 35; the upper surface of the drill rod 34 is fixedly connected with a limiting block 37; the limiting block 37 fits with the limiting groove 36, and the upper end of the drill rod 34 penetrates In the limiting groove 36, a first spring 38 is fixedly connected to the inner wall of the top of the limiting groove 36; a fixing plate 33 is arranged under the fifth gear 32; the fixing plate 33 is fixed to the inner wall of the frame 1; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com