Turning equipment

A processing equipment and turning technology, which is applied in the field of mechanical manufacturing and processing, can solve problems such as cracks and deformation, workpiece vibration, and waste of production costs, so as to reduce the probability of fracture, improve processing accuracy, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

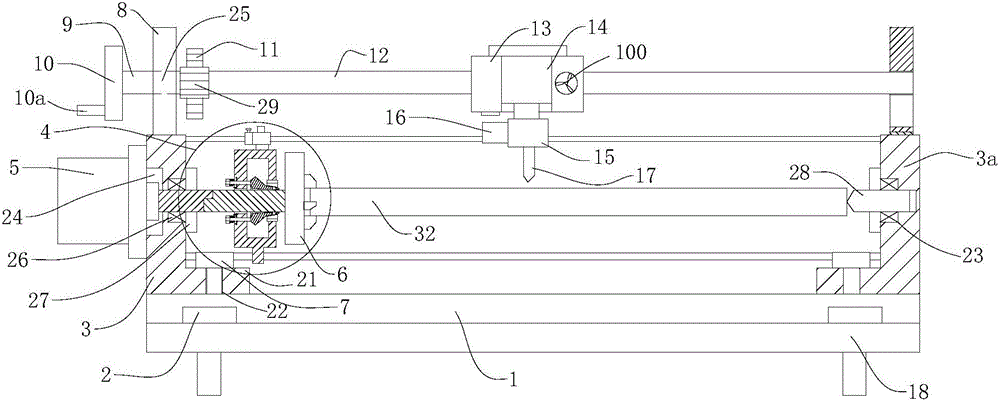

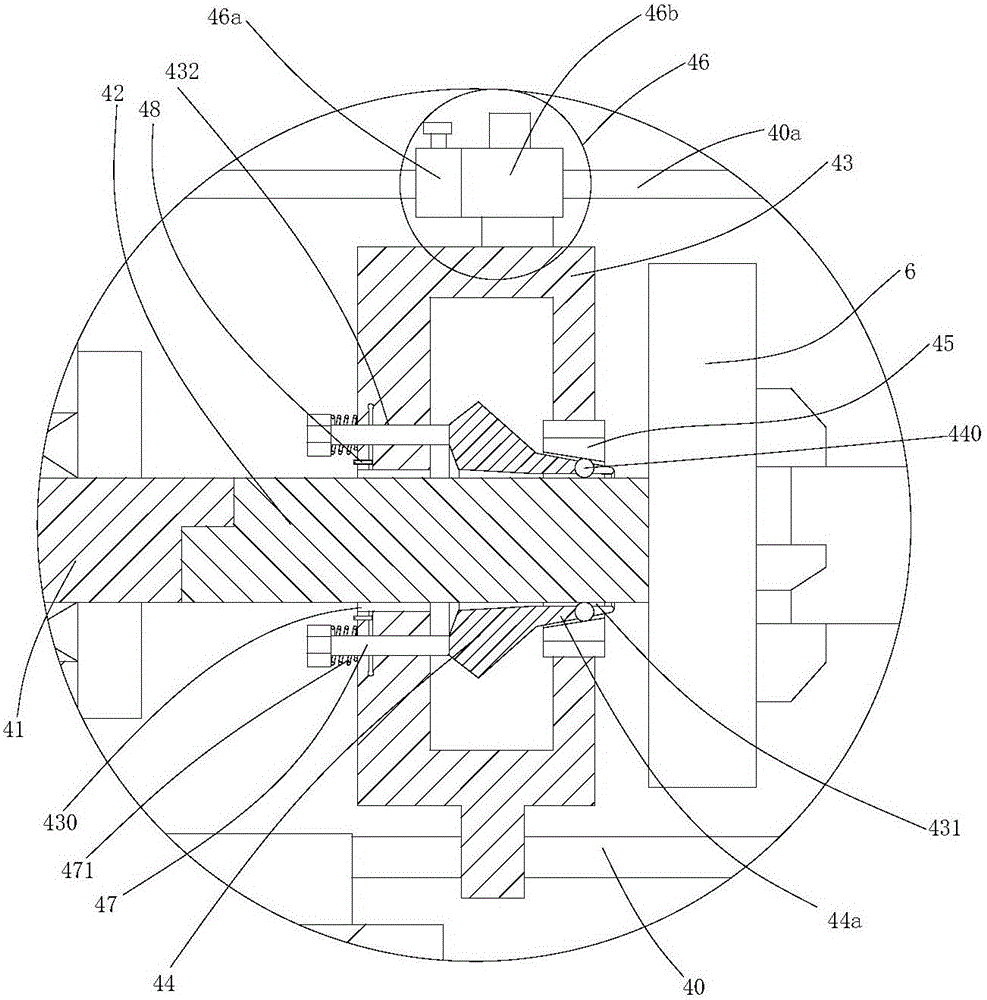

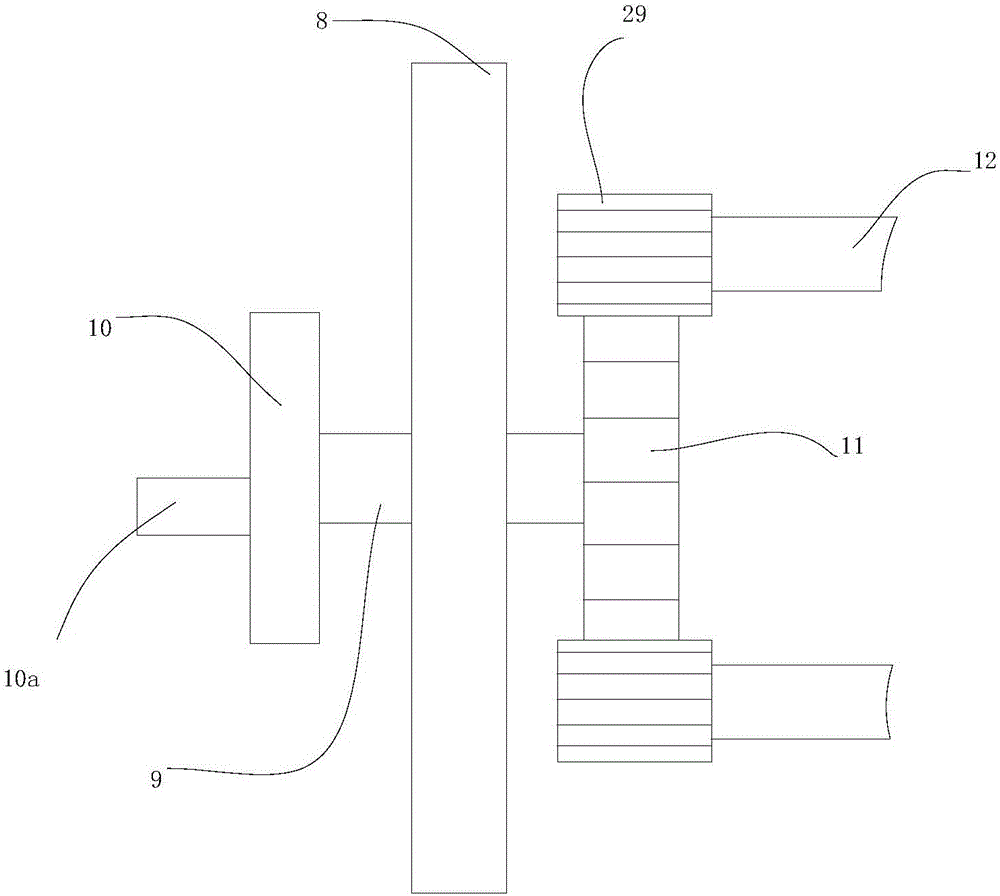

[0032] The turning equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] refer to Figure 1 to Figure 8 The turning processing equipment shown is mainly composed of a base 1, a left frame 3, a right frame 3a and a lathe mechanism. The lathe mechanism includes a moving mechanism and a turning assembly; see Figure 5 As shown, in order to fix the base 1, the base 1 is provided with four anchor bolt holes 19, the base 1 is fixedly connected to the ground through the anchor bolts 2, and the bolts are used to connect and disassemble, which facilitates the moving of the machine in the future. Both sides of the base 1 are also provided with fixed steps 18, that is, both sides of the base 1 are stepped, which facilitates the installation of the anchor bolts 2 on the one hand, and saves the cost of making the base 1 on the other hand. The base 1 is also provided with four screw holes 20, and the left frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com