Assembling unit for exerting prestress on glass fiber reinforced plastic anchor bolt and using method thereof

A fiberglass and prestressed technology, applied in the installation of bolts, earthwork drilling, construction, etc., can solve the problems of low torque resistance, unbearable, cracking, etc., to increase strength, improve reinforcement effect, improve performance and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

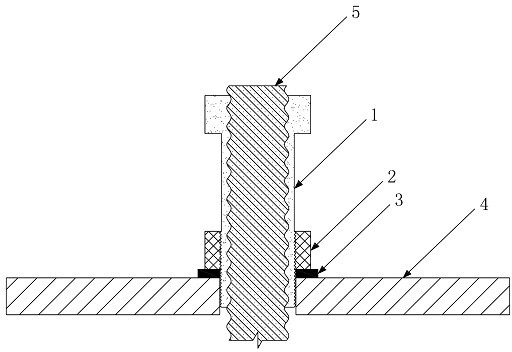

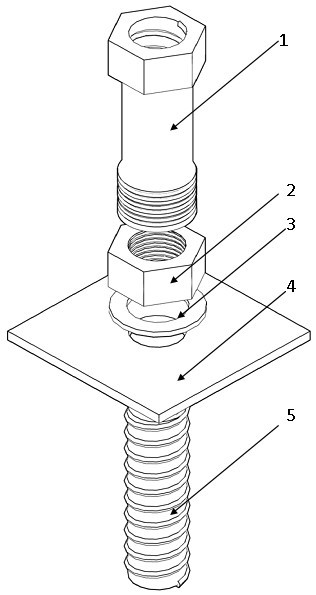

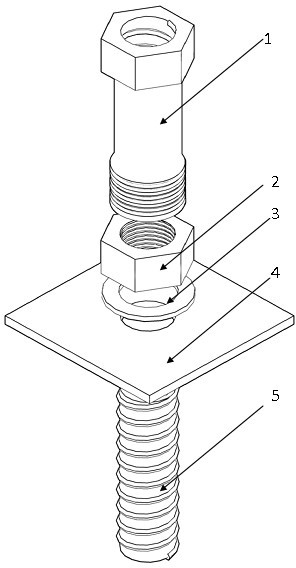

[0018] Such as figure 1 , 2 As shown in the figure, an assembly for prestressing the FRP bolt includes a steel sleeve 1 with an external thread on the outer wall at one end, a nut 2 used in conjunction with the external thread, and a gasket 3 arranged at the lower end of the nut 2. The inner wall at one end of the quality casing 1 provided with an external thread is also provided with an internal thread for cooperating with and fixing the fully threaded glass fiber reinforced plastic anchor rod 5 .

[0019] The other end of the steel casing 1 is also provided with a prism with a regular polygonal cross section, a cylindrical tube between the prism and the external thread, and the nut 2 is a steel nut, which is matched with the external thread of the steel casing 1; the gasket 3 is made of ring-shaped metal or polymer material.

[0020] In this embodiment, the cross section of the prism is a regular hexagon, its outer diameter is 32mm, and the height of the hexagonal prism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com