Axial stretching test device for cement based composite material test piece

A composite material and axial stretching technology, which is applied to measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problem of inaccurate centering of the axis, improve the overall stiffness and reduce the cost , Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

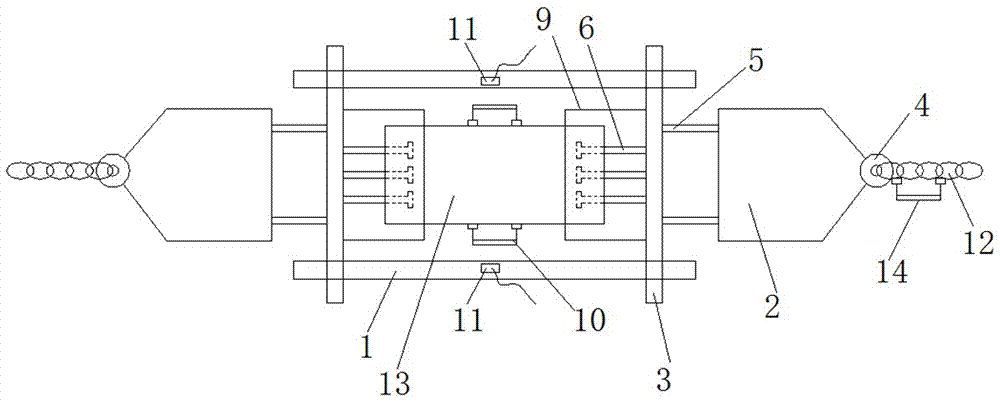

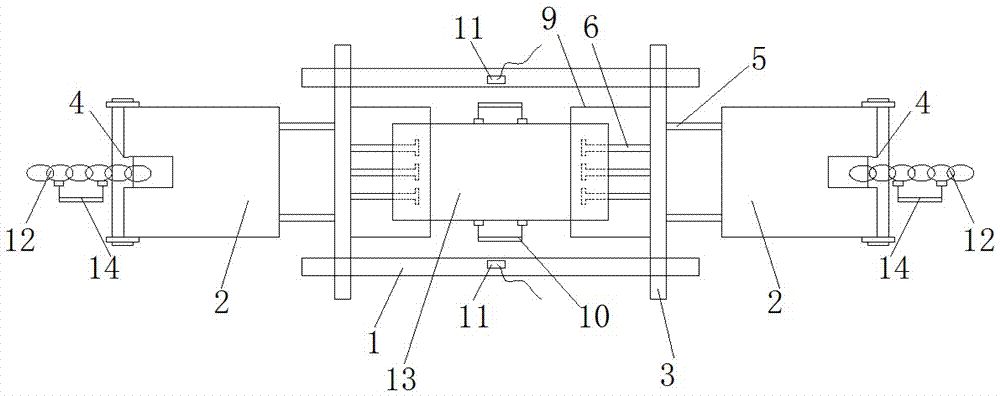

[0030] Such as figure 1 As shown, the present invention provides a kind of axial tensile test device of cement-based composite material specimen, and this device comprises frame assembly 1, spherical joint assembly 2, slidable frame assembly 3 and steel band 12; Frame assembly 1 connects and can slide The frame component 3 is slidable. The frame component 3 is connected to the ball joint component 2 , and the ball joint component 2 is connected to the steel belt 12 .

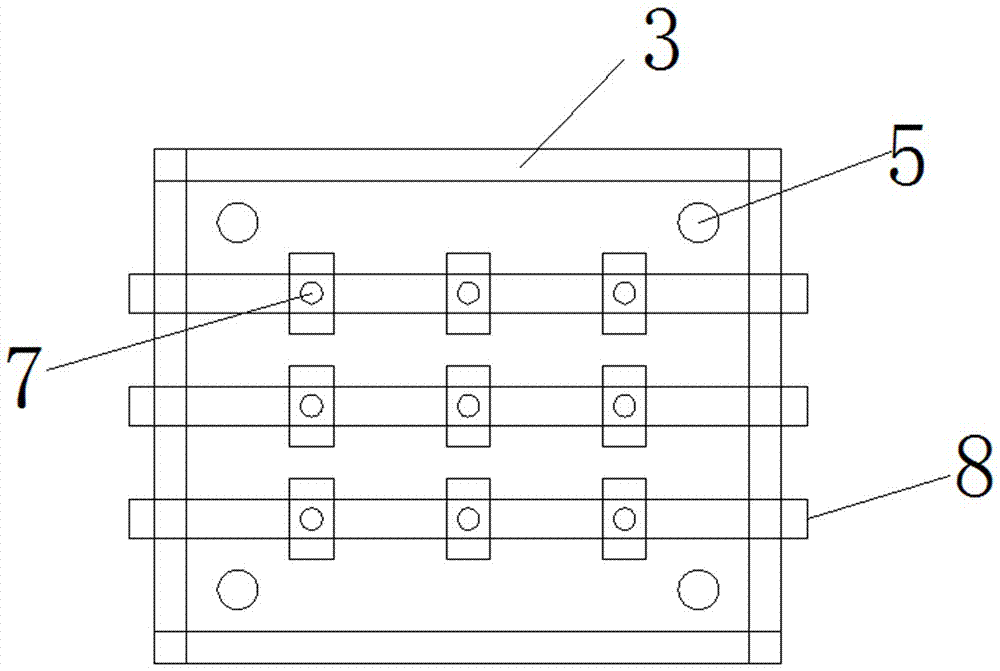

[0031] The slidable frame assembly 3 is equipped with a slidable rod 8 that can slide up and down on the slidable frame assembly, and the slidable rod 8 is provided with a slidable nut 7 that connects one end of the screw rod 6 when in use, and the other end of the screw rod 6 is used Pre-embedded in the test piece 13.

[0032] The slidable frame assembly 3 is connected to one end of the steel sheet 9, and the other end of the steel sheet 9 is connected to the test piece 13 through an adhesive during use.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com