Method for overturning precast concrete column with bent structure

A technology of prefabricated concrete and bent frames, which is applied in building construction, processing of building materials, construction, etc. It can solve the problems of prefabricated concrete columns such as breakage, heavy weight, and difficulty in turning over columns, and achieves a simple structure of the spreader device and easy fabrication. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

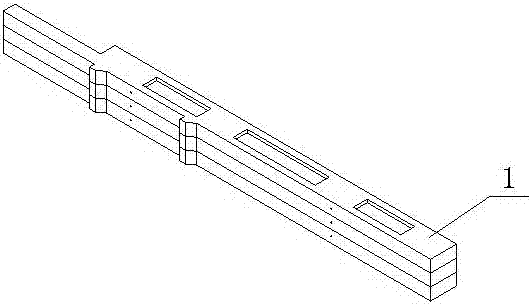

[0032] figure 1 It is a schematic diagram of stacking and placing three layers of prefabricated concrete columns after pouring and forming according to the embodiment of the present invention.

[0033] The turning method of the bent structure prefabricated concrete column of the present invention comprises the following steps:

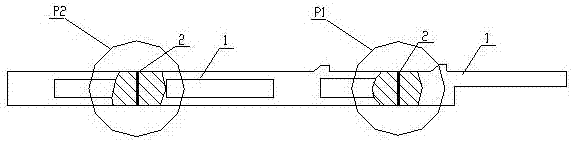

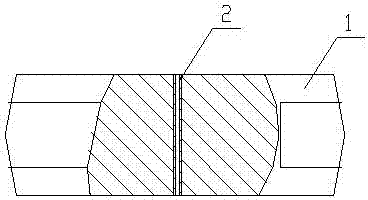

[0034] figure 2 It is a schematic diagram of two welded steel pipes pre-embedded in the prefabricated concrete column of the embodiment of the present invention, image 3 for figure 2 The enlarged view of the P2 site in Figure 4 for figure 2 Enlarged view of the P1 site in .

[0035] a. When pouring the precast concrete column 1 of the bent frame structure, in order to ensure the balance during hoisting, the two ends are at the same distance from the center of gravity, such as figure 2 In the P1 and P2 positions, a Φ60X3.5 welded steel pipe 2 with the same length as the column width is buried in the center in the thickness direction of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com