Pillow sleeve edge cutting turning production line

A production line and pillowcase technology, which is applied in the field of pillowcase trimming and flipping production line, can solve the problems of low work efficiency, manpower and material resources consumption, etc., and achieve the effect of improving efficiency, improving work efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

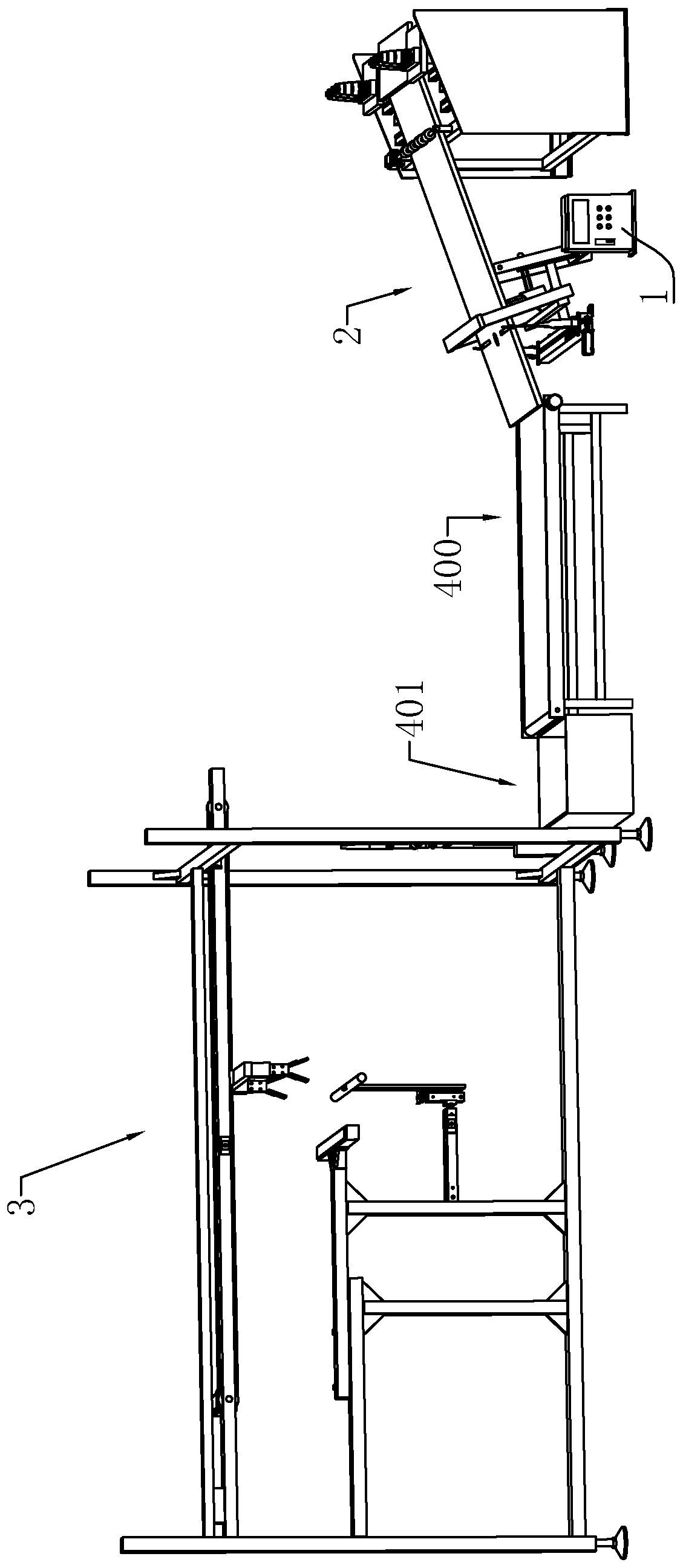

[0046] Embodiment: a kind of production line of trimming and turning over pillowcase, such as figure 1 As shown, it includes a pillowcase trimming device 2, a pillowcase turning storage device 3 and a control box 1. The pillowcase turning storage device 3 is located at the next station of the pillowcase trimming device 2, and the pillowcase trimming device 2 and pillowcase turning storage device 3 is provided with a pulley transmission mechanism 400, and a storage box 401 is provided between the pulley transmission mechanism 400 and the pillowcase turning storage device 3.

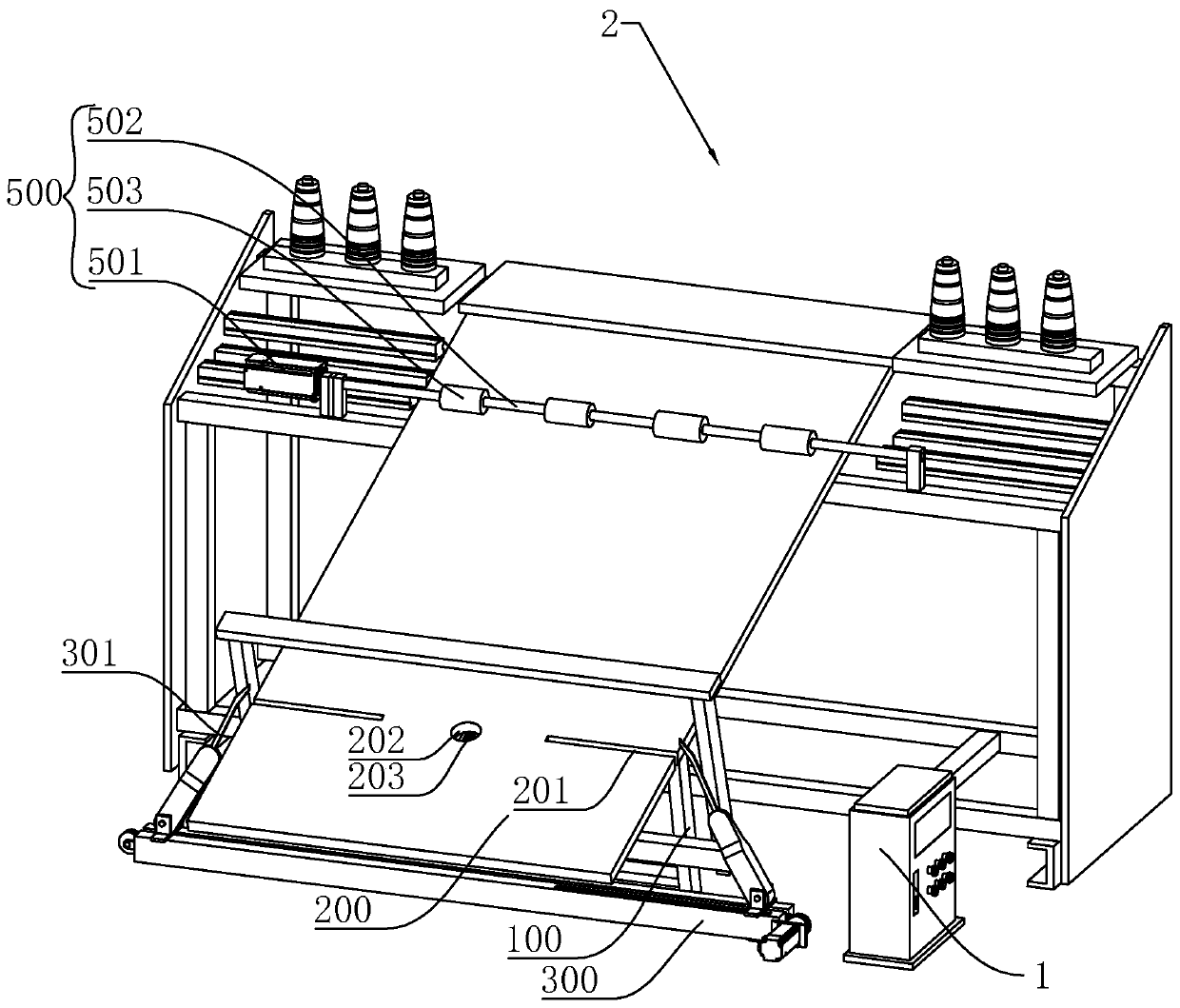

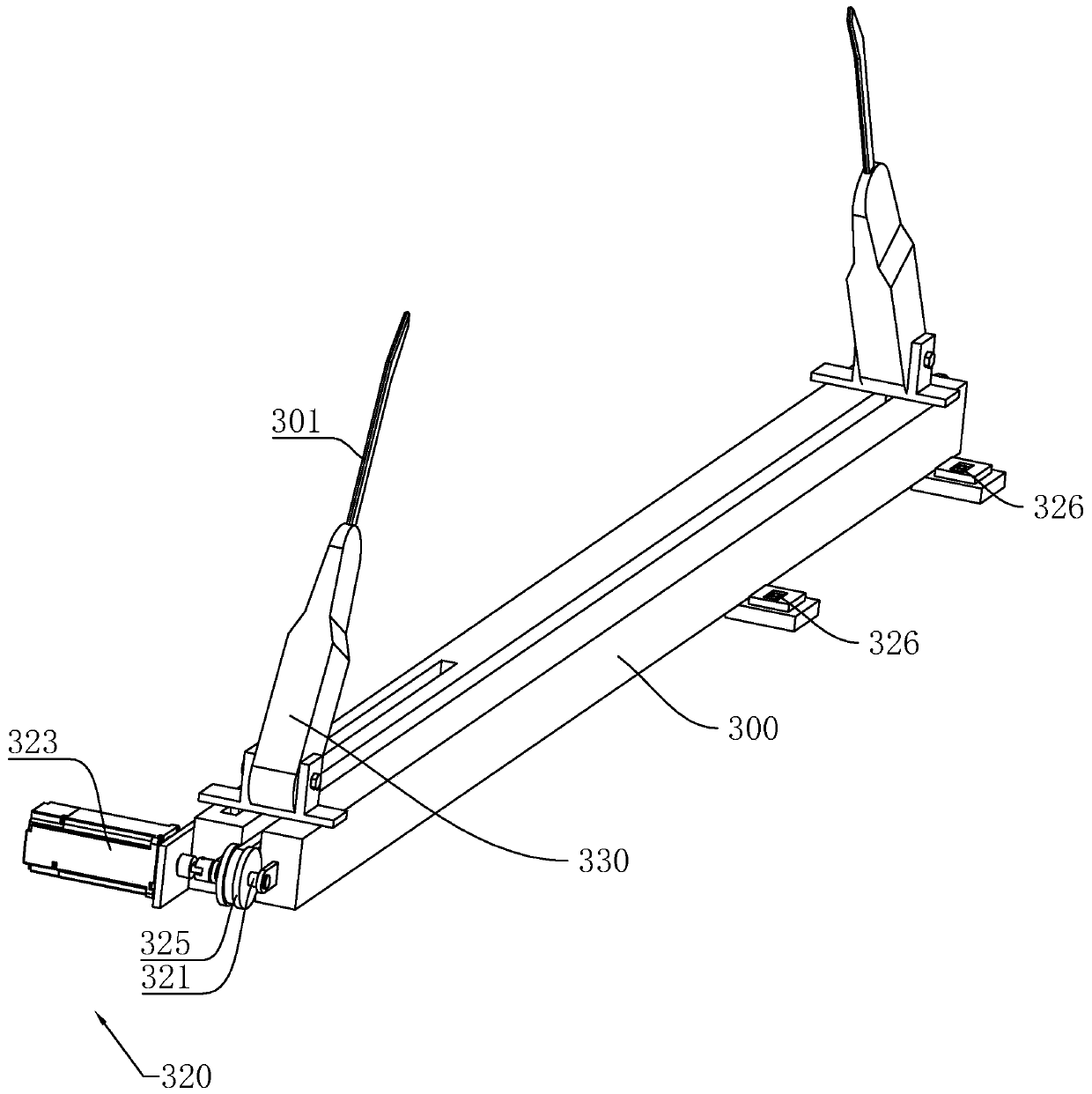

[0047] Such as figure 2 with 3 As shown, the pillow case trimming device 2 includes a trimming support 100, and the trimming support 100 is provided with an inclined working panel 200. The working panel 200 is provided with two cutting grooves 201 arranged on the same line. Pillowcase advancing direction is set, edge trimming support 100 is provided with edge trimming slide rail 300 that is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com