Turning processing method of wheel groove milling cutter

A technology of wheel groove milling cutter and processing method, which is applied in the field of turning processing, can solve the problem of consistent axial dimension of wheel groove milling cutter profile, achieve the effects of shortening auxiliary time, improving turning processing efficiency, and optimizing turning processing mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

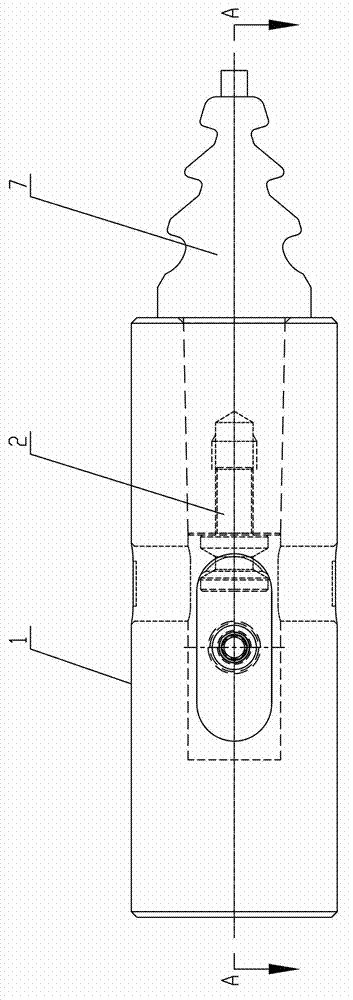

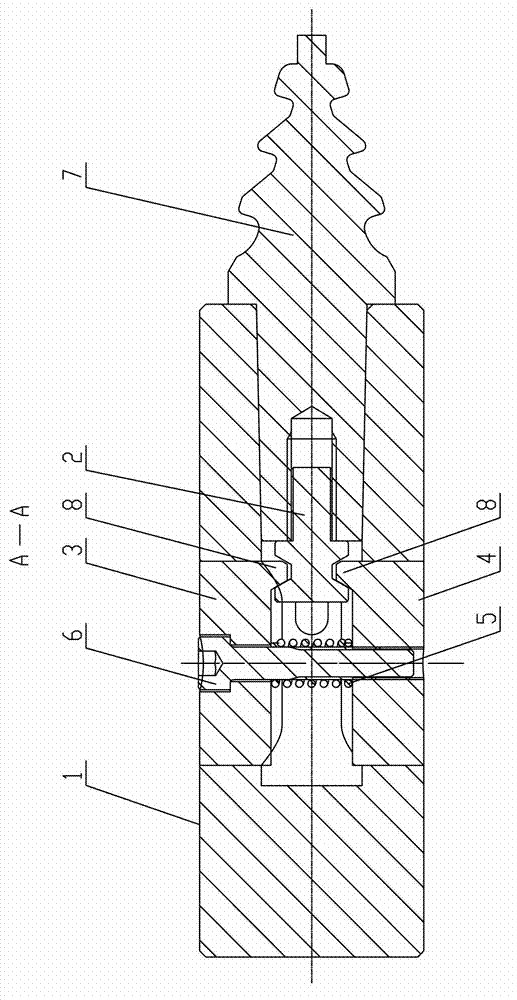

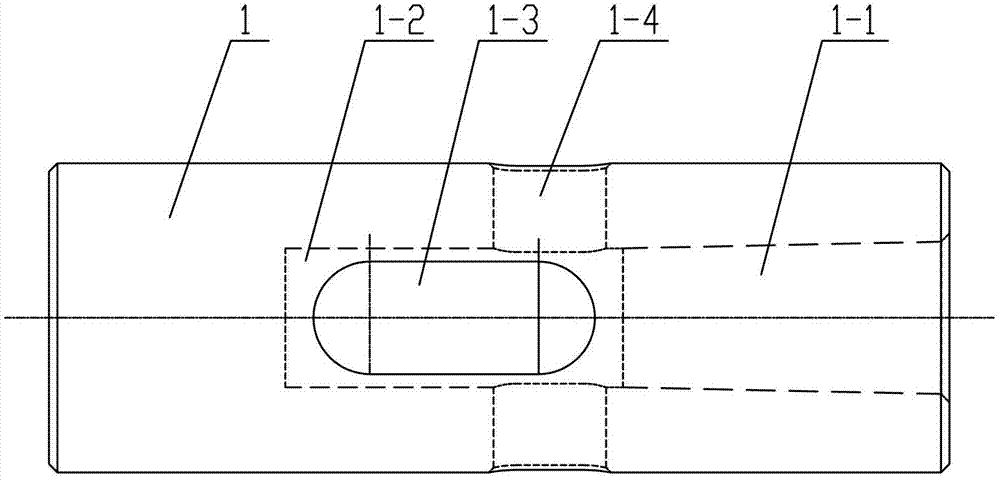

[0012] Specific implementation mode one: combine Figure 1 to Figure 13 Describe this embodiment, a wheel groove milling cutter turning fixture described in this embodiment includes a clamp body 1, a tension screw 2, an upper clamp block 3, a lower clamp block 4, a compression spring 5 and a connecting screw 6, and the clamp body 1 is Cylinder, the center of the matching end face of the clamp body 1 and the wheel slot milling cutter 7 is processed with an interconnected inner taper hole 1-1 and a cylindrical hole 1-2, and the inner taper hole 1-1 is used for positioning and assembly wheel slot milling The shank 7-1 of the knife 7, the outer surface of the clamp body 1 runs through the limiting waist hole 1-3 and the unloading waist hole 1-4 along the radial direction, and the limiting waist hole 1-3 and the unloading waist hole 1-4 is vertically arranged, and the screw rod 2-1 of tensioning screw 2 is used for being threadedly connected with the knife handle 7-1 of wheel groov...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the specific steps of a method for turning a wheel groove milling cutter using the jig described in Embodiment 1 described in this embodiment are as follows:

[0014] Step 1, turning and processing the wheel groove milling cutter blank on a common lathe, the lathe speed is 400r / min, the feed rate is 0.2mm / r-0.4mm / r, and the cutting depth is 1.4mm-1.6mm;

[0015] Step 2: Use the four-claw chuck on the CNC lathe to clamp the wheel groove milling cutter turning fixture, and perform alignment, and then insert one end of the tension screw 2 into the threaded hole of the wheel groove milling cutter blank, The other end of the tension screw 2 is clamped between the upper clamp block 3 and the lower clamp block 4, and the upper clamp block 3 and the lower clamp block 4 clamp the other end of the tension screw 2 through the connecting screw 6;

[0016] Step 3: Use a 55°rhombic t...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, in Step 1 of the method for turning a wheel groove milling cutter described in this embodiment, when turning a wheel groove milling cutter blank on a common lathe, the feed rate of the lathe is 0.3mm / r, and the cutting depth is 1.5mm. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com