Steel plate overturning mechanism

A technology of flipping mechanism and steel plate, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of large hidden dangers in operation, incapable of manual handling, large area of steel plate, etc., so as to save production costs, save labor and turn high surface efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

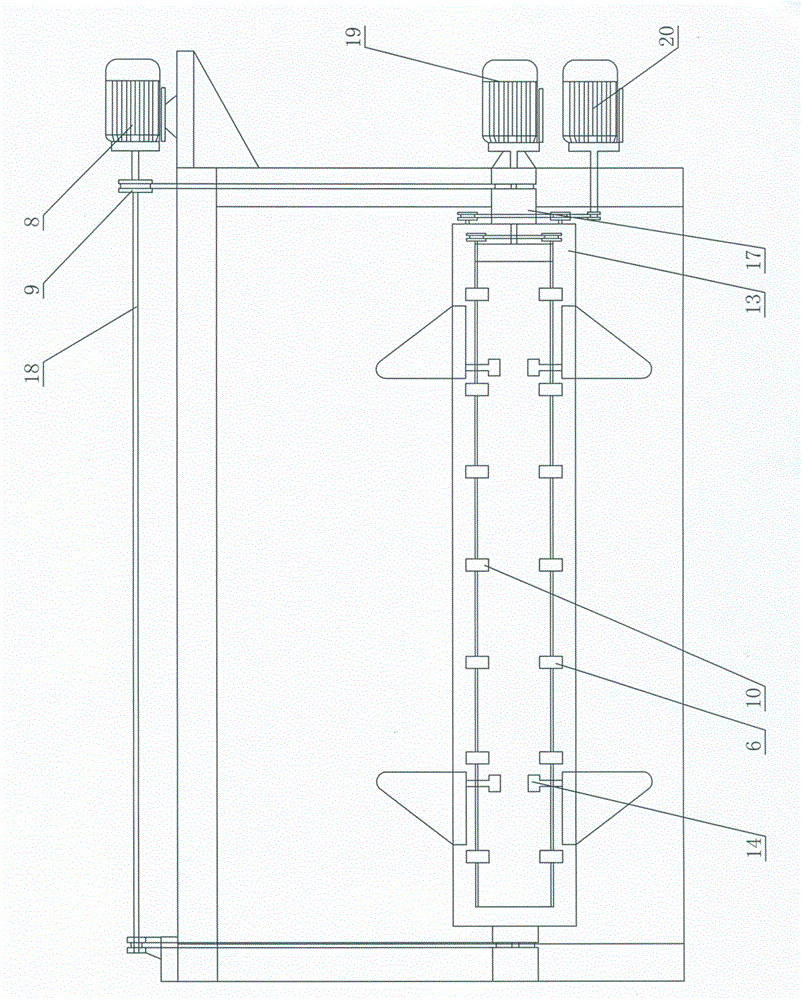

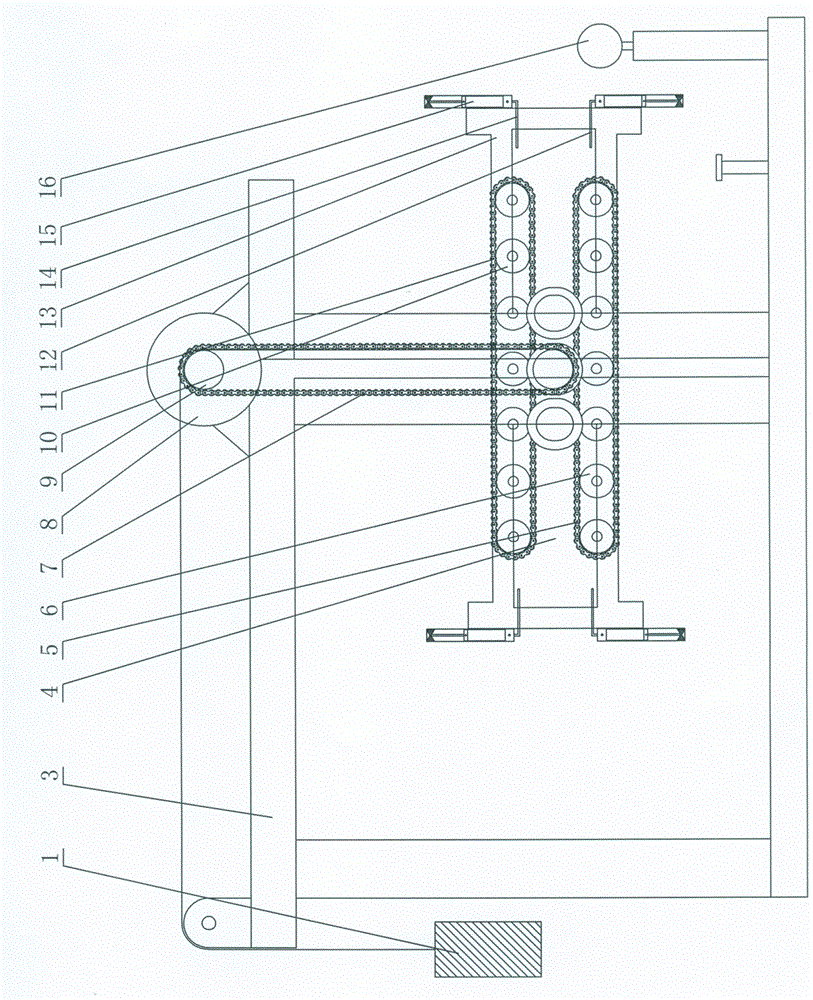

[0017] The working principle and relevant details of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] With reference to accompanying drawing, this kind of steel plate overturning mechanism, comprises frame and is installed on the feeding device on the frame 3 and overturning device, and described feeding device includes conveying roller 16, and described conveying roller 16 and the steel plate output of overturning device or The entered height is contoured. The overturning device includes a bracket 13, an upper transmission part, a lower transmission part, a clamping part clamping a steel plate on the upper transmission part or the lower transmission part, and a steel plate overturning part, between the upper transmission part and the lower transmission part There is a distance of 4 for the steel plate to be conveyed, that is, the steel plate enters the lower transmission part from the feeding device and is conveyed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com