Boxing packaging machine for machined and formed boards

A technology of packing, packaging, processing and forming, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of time-consuming, cumbersome work, low work efficiency, etc., and achieve the effect of saving effort, reducing cost loss and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

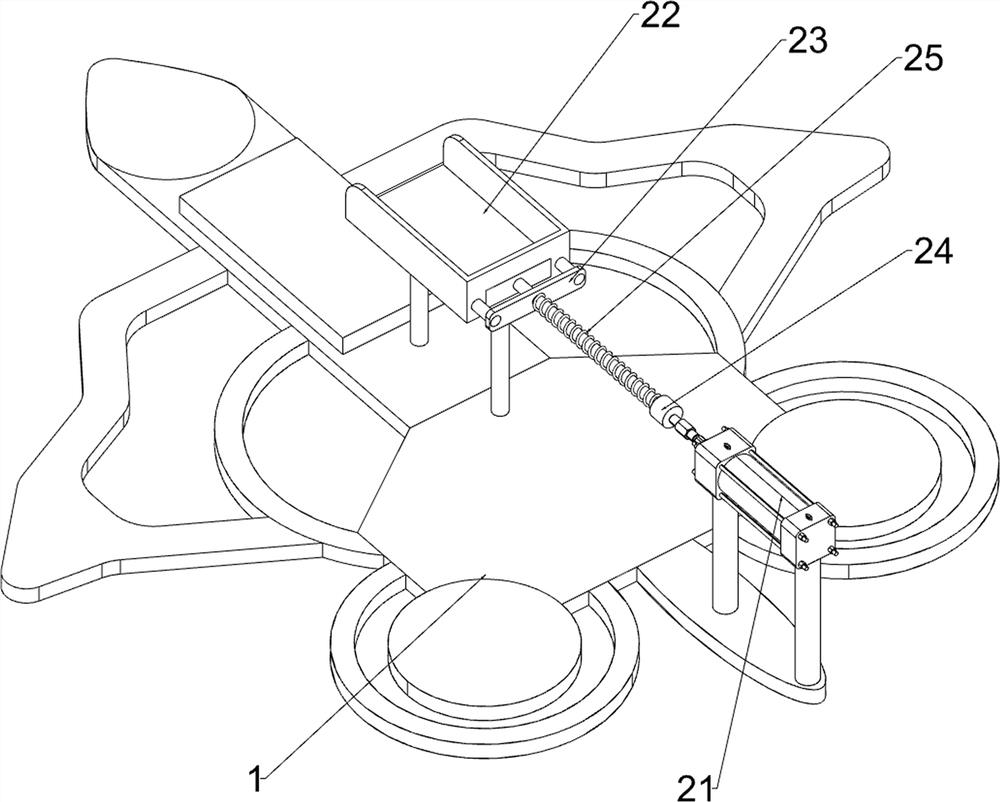

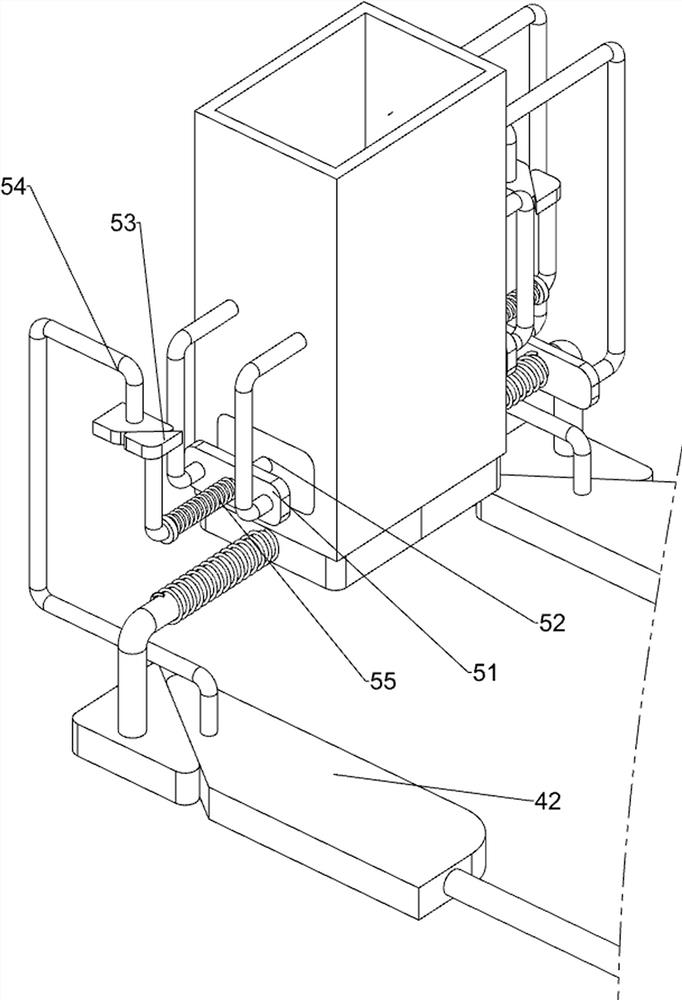

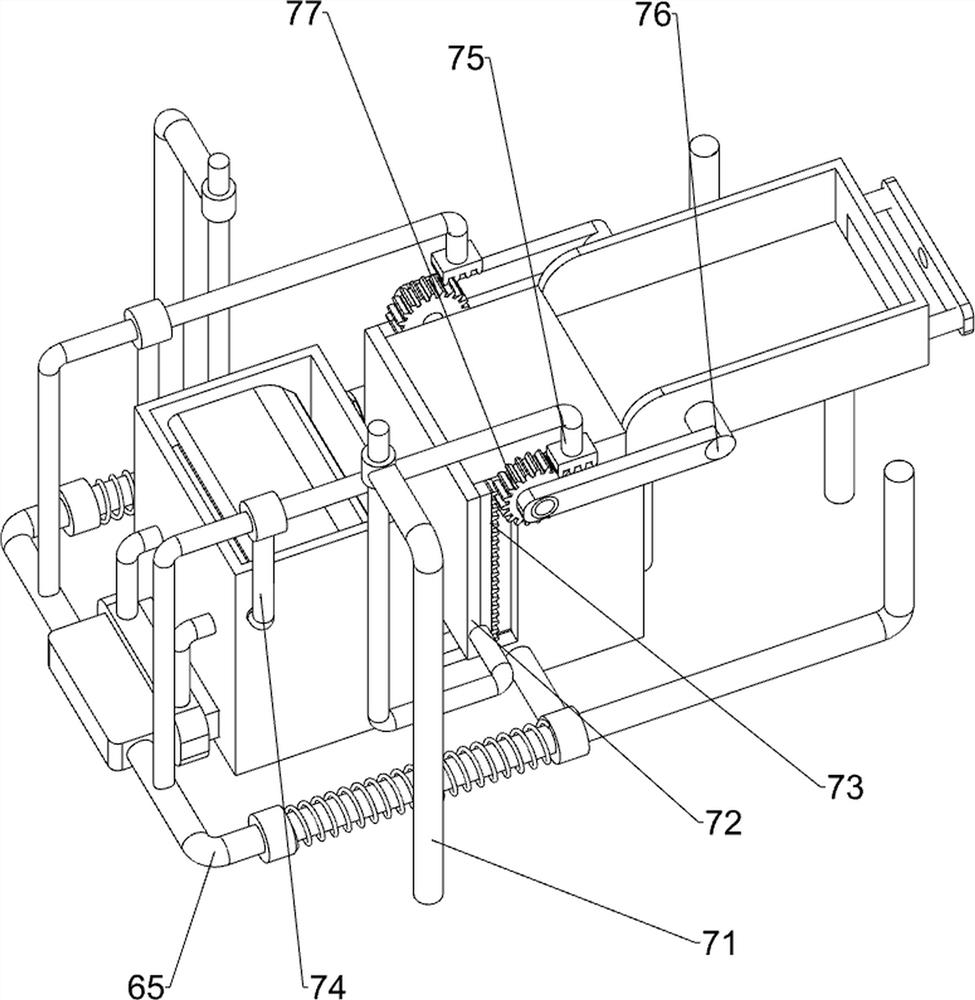

[0065] A kind of packing and packaging machine for processing and forming wooden boards, such as figure 1 As shown, it includes a bottom plate 1, a material pushing mechanism 2, a material opening mechanism 3, an automatic intermittent discharging mechanism 4 and an intermittent clamping mechanism 5. The upper and middle part of the bottom plate 1 is provided with a material pushing mechanism 2, and the bottom plate 1 is provided with a material opening mechanism. 3. An automatic intermittent feeding mechanism 4 is provided in the upper middle of the bottom plate 1, and an intermittent clamping mechanism 5 is provided between the opening mechanism 3 and the automatic intermittent discharging mechanism 4.

[0066] When people need to pack the planks, they place some planks in the opening mechanism 3, and people open the pushing mechanism 2, so that the pushing mechanism 2 will move the automatic intermittent discharging mechanism 4 to the rear side, so that the opening mechanism...

Embodiment 2

[0068] On the basis of Example 1, such as figure 2 As shown, the pushing mechanism 2 includes a cylinder 21, a feeding frame 22, a first fixed sliding sleeve plate 23, a first pushing plate 24 and a first spring 25, and the front side of the upper middle part of the base plate 1 is provided with a cylinder 21. There is a feeding frame 22 in the middle, and a first fixed sliding sleeve plate 23 is provided on the front side of the feeding frame 22. The output shaft of the cylinder 21 is connected with a first pushing plate 24, and the first pushing plate 24 is slidingly connected with the feeding frame 22. , the first push plate 24 is covered with a first spring 25, and the two ends of the first spring 25 are respectively connected with the first push plate 24 and the first fixed sliding sleeve plate 23.

[0069] When people put some wooden boards in the cutting mechanism 3, people open the cylinder 21, so that the output shaft of the cylinder 21 pushes the first push plate 24...

Embodiment 3

[0071] On the basis of Example 2, such as figure 1 , Figure 3-Figure 7 As shown, the material opening mechanism 3 includes a material storage frame 31, a second fixed sliding sleeve plate 32, a sliding intermittent material blocking plate 33 and a second spring 34. The upper middle part of the bottom plate 1 is provided with a material storage frame 31, and the material storage frame 31 is located at The upper side of the feeding frame 22, the left and right sides of the storage frame 31 are provided with a second fixed sliding sleeve plate 32, and the inner sides of the two second fixed sliding sleeve plates 32 are all slidingly provided with a sliding intermittent blocking plate 33. The intermittent material retaining plate 33 is slidingly connected with the material storage frame 31, and the middle part of the two sliding intermittent material retaining plates 33 is covered with a second spring 34, and the two ends of the second spring 34 are connected with the sliding int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com