Return way structure of ball screw

A ball screw and ball technology, used in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of interfering with the rolling of balls, the spacer touching the inner edge wall of the return curve, and the balls, etc., to achieve the degree of bending soothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

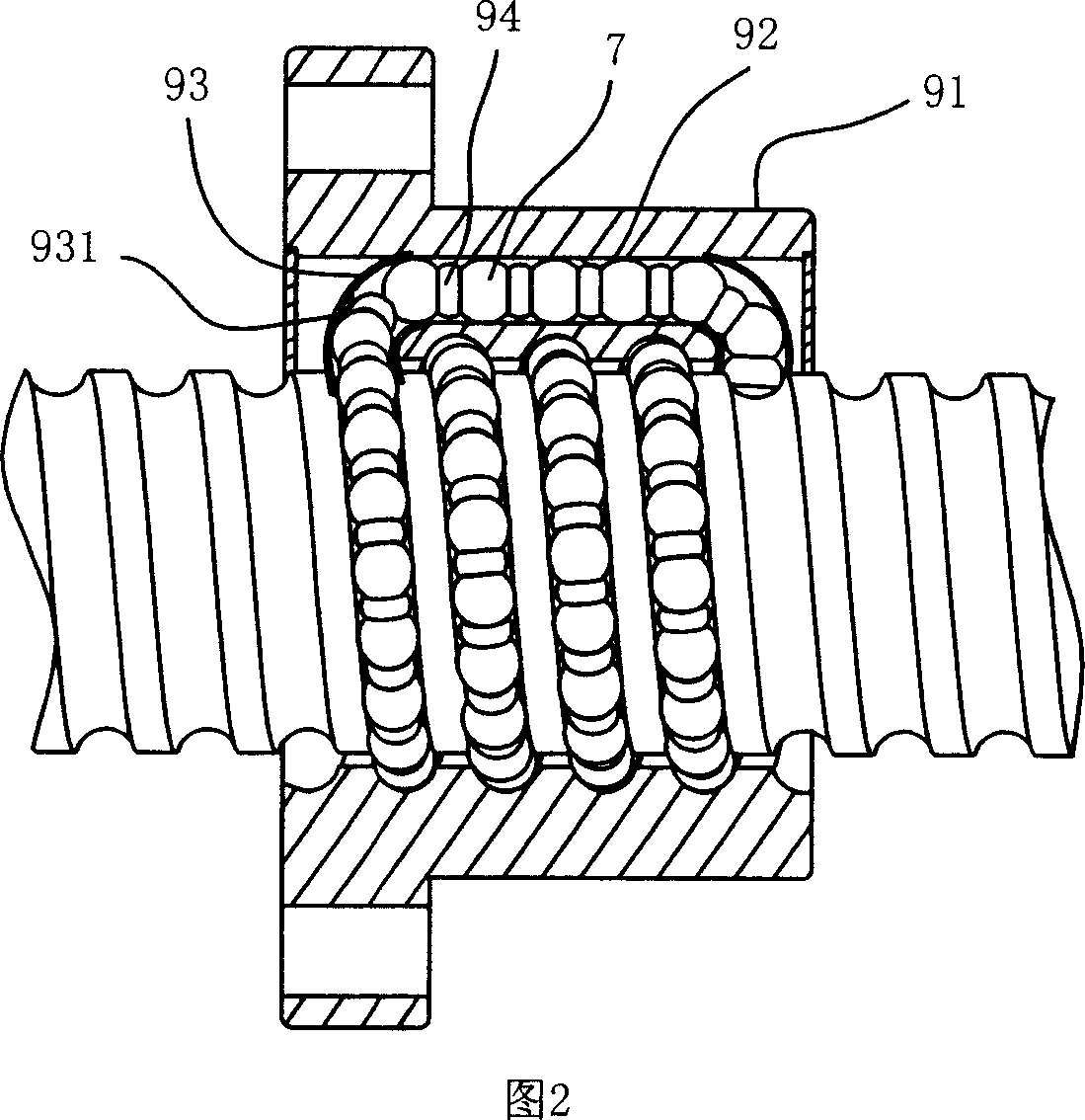

[0034] Please refer to Fig. 6-Fig. 8, the ball screw of the present embodiment is constituted by a screw 1 and a nut 2 passing through each other, and the screw 1 and the nut 2 are oppositely provided with spiral grooves 11, 21 for A plurality of balls 3 and a plurality of spacers 4 spaced between two adjacent balls are accommodated therein, and the nut 2 is provided with an axially extending return hole 22, and one end is respectively provided at the two ends of the return hole 22 Plug 5, and each end plug 5 has a return channel structure to respectively connect the spiral groove 21 and the return hole 22, so that the plurality of balls 3 and the plurality of spacers 4 can flow back and circulate in the nut 2.

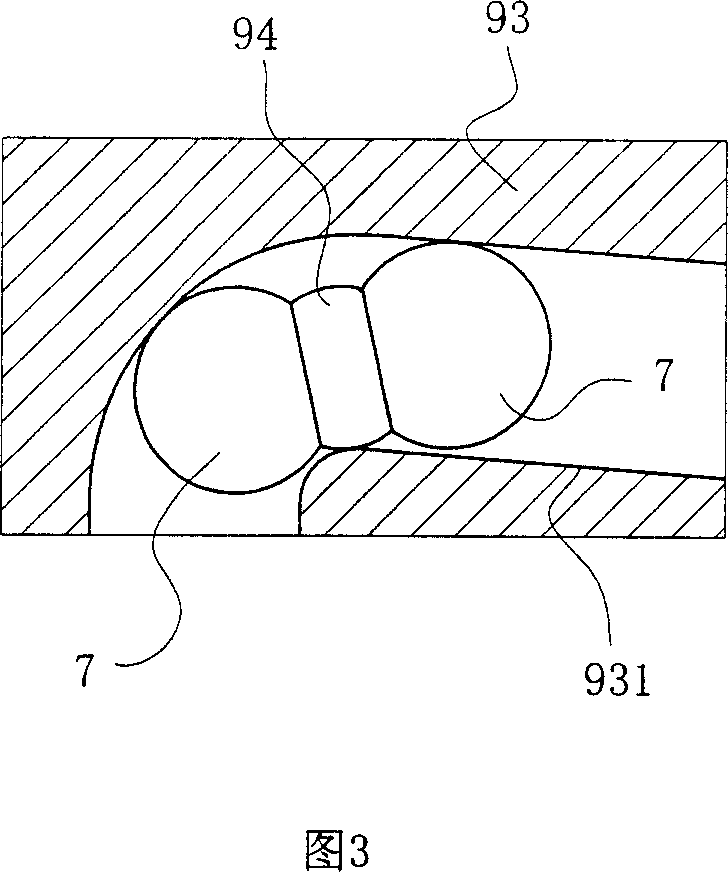

[0035] Please refer to FIG. 7 , the backflow path structure includes a backflow bend 51 and two linear guides 52 and 53 respectively connecting the two ends of the backflow bend with the spiral groove 21 and the return hole 22 , the backflow bend 51 It is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com