Indoor inspection robot for transformer substation

A technology for inspection robots and substations, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high position of the equipment to be inspected, difficult to implement, and prohibitive inspection methods, and achieves stable and reliable communication and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

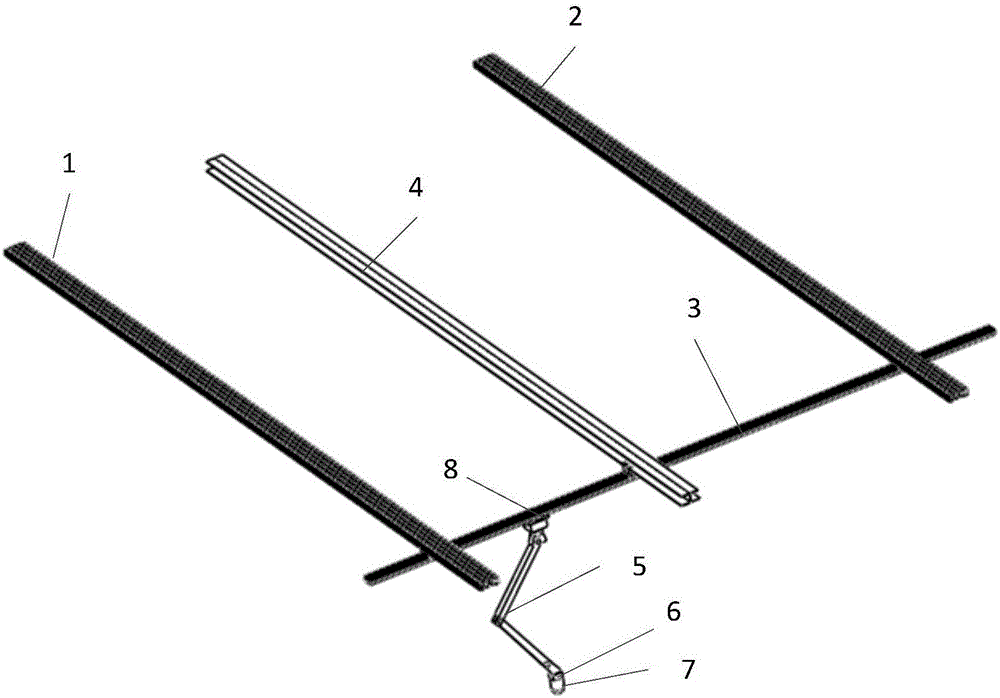

[0044] like figure 1 Described is the structural representation of the present invention. The present invention mainly comprises XY combined track, support assembly 4, mechanical arm 5, mobile platform 8, pan platform 6, detection assembly 7; Described mobile platform 8 below is installed mechanical arm 5, and mechanical arm 5 has 4 degrees of freedom, and its end A detection component 7 and a cloud platform 6 are installed.

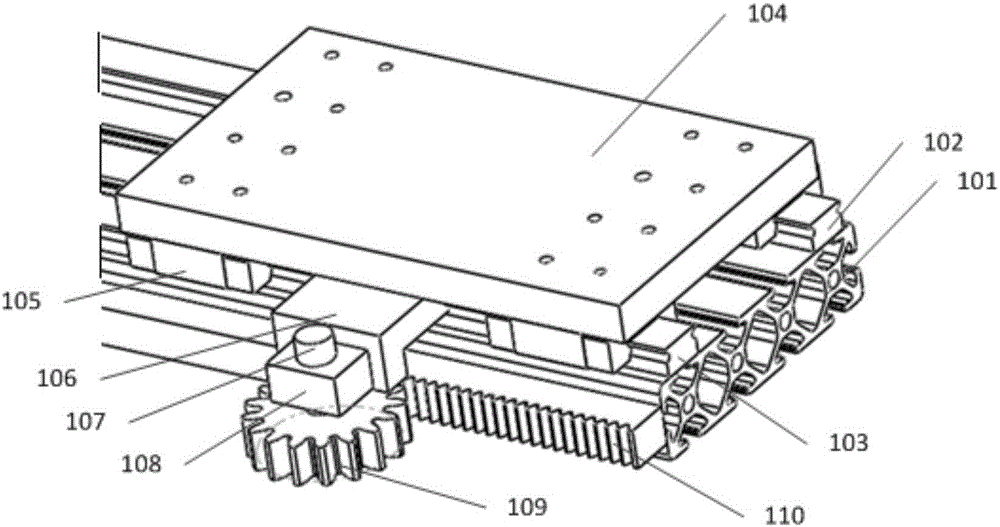

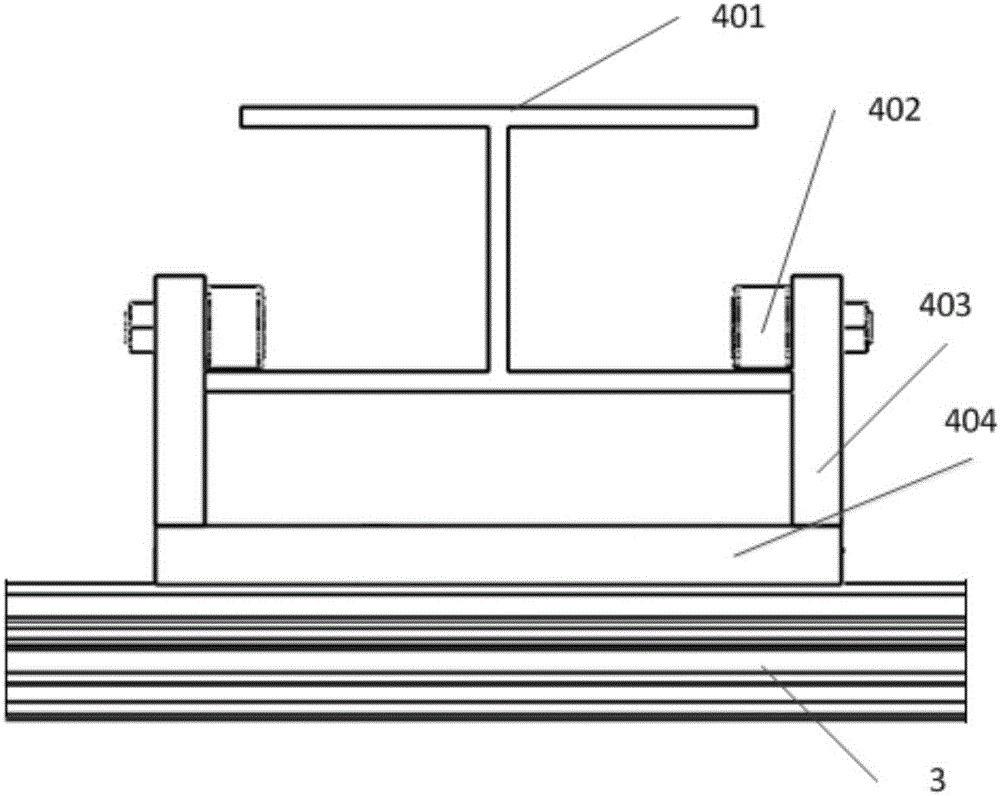

[0045]The XY combined track includes the first X-axis 1, the second X-axis 2 and the Y-axis 3 with the same structure; the first X-axis 1 and the second line X-axis 2 are arranged in parallel, and are respectively orthogonal to the Y-axis 3; the Y-axis 3 Connect the first X-axis 1 and the second X-axis 2 at the same time, and can move linearly along the axial direction of the first X-axis 1 and the second X-axis 2; the mobile platform 8 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com