Rolling gear of turbine

A cranking device and steam turbine technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as limited reduction ratio, potential safety hazards, and large geometric dimensions, so as to improve transmission efficiency, eliminate potential safety hazards, and geometrically small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

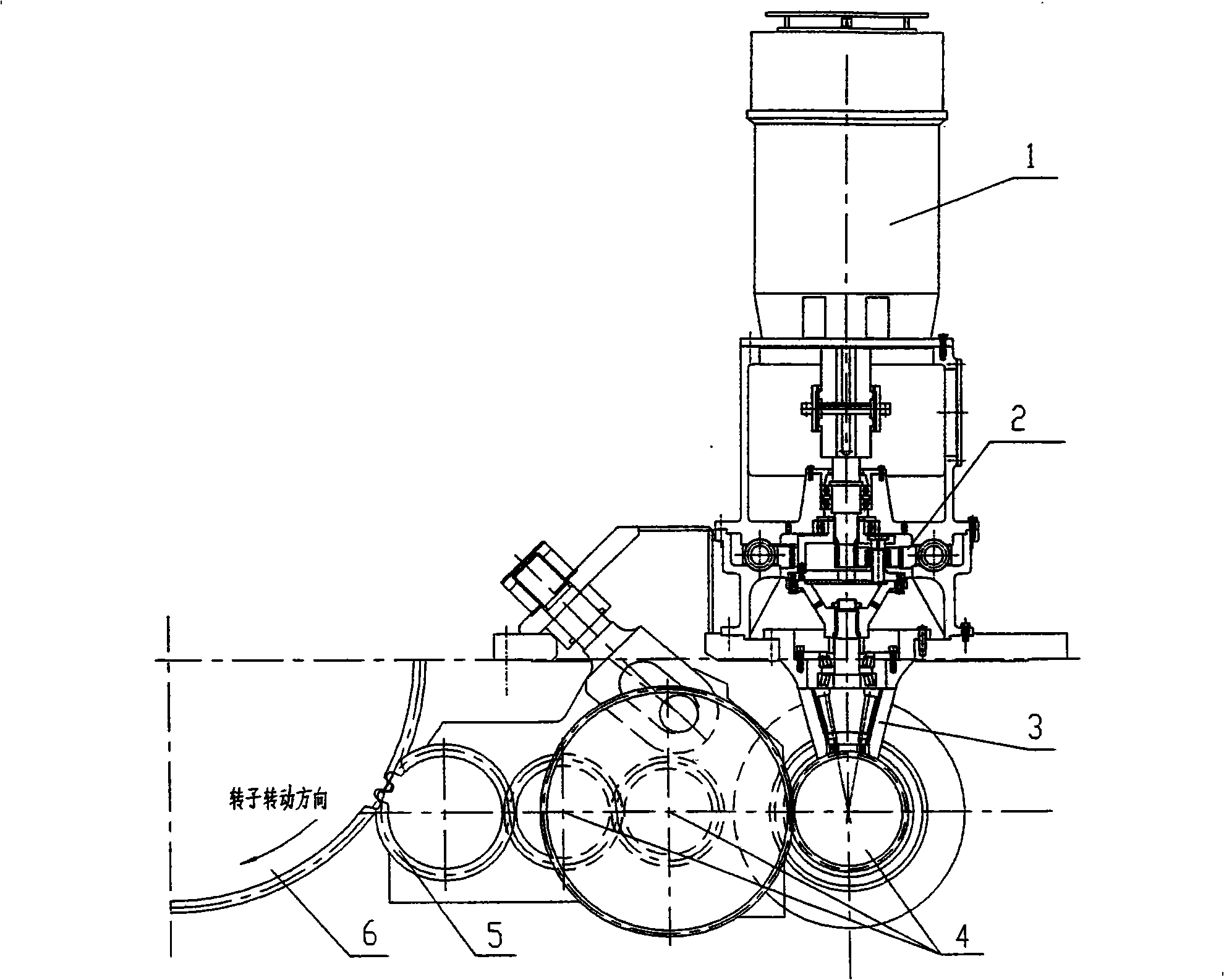

[0029] see figure 1 : This device comprises drive motor 1, planetary gear transmission box 2, bevel gear transmission pair 3, parallel shaft gear reduction transmission pair 4, swing gear 5, ring gear 6, and the clutch mechanism of swing gear 5 connected in sequence. Among them: the large ring gear 5 is arranged on the rotor of the steam turbine; the driving motor 1 and the star gear transmission box 2 are arranged vertically above the parallel shaft gear reduction transmission pair 4, and are connected with the parallel shaft gear reduction transmission pair 4 through the bevel gear transmission pair 3 , to change the direction of power transmission.

[0030] Compared with the traditional worm gear / worm or sprocket, the star gear transmission box has a larger reduction ratio, which reduces the number of stages of the parallel shaft gear reduction transmission pair. This device only uses 4 parallel shaft gear reduction transmission pairs, which is The requirement of 2r / min is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com