Vibration reduction milling cutter based on layered superposition type permanent magnet dynamic vibration absorber

A technology of dynamic vibration absorber and dynamic vibration absorber, which is applied in the field of machining, can solve the problems of insufficient magnetic stiffness and eddy current damping of dynamic vibration absorber, and achieves the solution of rubber fatigue aging, dissipation of vibration energy, durability and stability. The effect of sexual assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

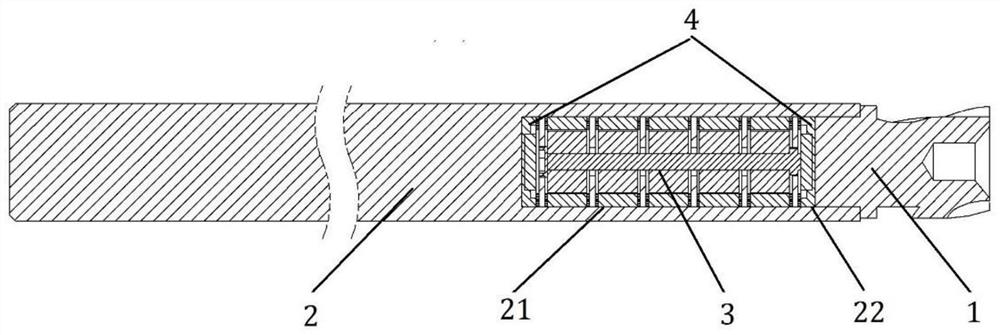

[0027] A vibration-damping milling cutter based on a layered superimposed permanent magnet dynamic vibration absorber, the dynamic vibration-damping milling cutter includes a cutter head 1, a cutter bar 2, a permanent magnet dynamic vibration absorber 3 and an axial thrust end cover 4, The end of the cutter bar 2 close to the cutter head 1 is provided with a cylindrical cavity 21, the permanent magnet dynamic shock absorber 3 and the axial thrust end cover 4 are installed in the cylindrical cavity 21, and the cutter head 1 is fixedly installed on the cutter bar through threaded connection. Inside the cylindrical cavity 21.

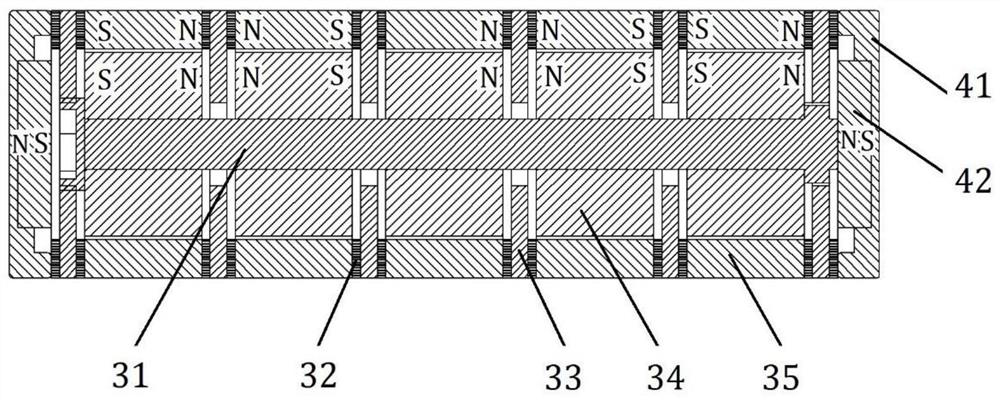

[0028] The permanent magnet dynamic shock absorber includes a connecting rod 31, a rubber gasket 32, a metal sheet 33, an inner magnetic ring 34 and an outer magnetic ring 35, wherein the magnetization directions of the inner magnetic ring 34 and the outer magnetic ring 35 are both axial magnetization, All the inner magnetic rings 34 form a vibrator togeth...

Embodiment 2

[0033] When the dynamic damping milling cutter based on magnetic stiffness and eddy current damping cannot achieve the optimal vibration damping effect during use, the external magnet of the permanent magnet dynamic damper can be squeezed by changing the screw-in depth of the axial thrust end cover 4 Ring 35, under the elastic action of rubber gasket 32, the gap size of outer magnetic ring 35 can be slightly adjusted, changing the gap size between inner magnetic ring 34 and metal sheet 33, and then changing the size of the eddy current damping coefficient.

[0034] The heights of the inner magnetic ring 34 and the outer magnetic ring 35 in the permanent magnet dynamic shock absorber 3 are the same. When there is no axial offset between the inner magnetic ring 34 and the outer magnetic ring 35, the inner magnetic ring 34 and the outer magnetic ring The radial stiffness between 35 and 35 is the largest. By adjusting the axial screw-in depth of the axial thrust end cover 4 to chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com