Beam ring force sensor

A force sensor and ring technology, applied in the field of sensors, can solve problems such as inconvenience to use, achieve high suppression ability, and overcome the effect of being susceptible to lateral force interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

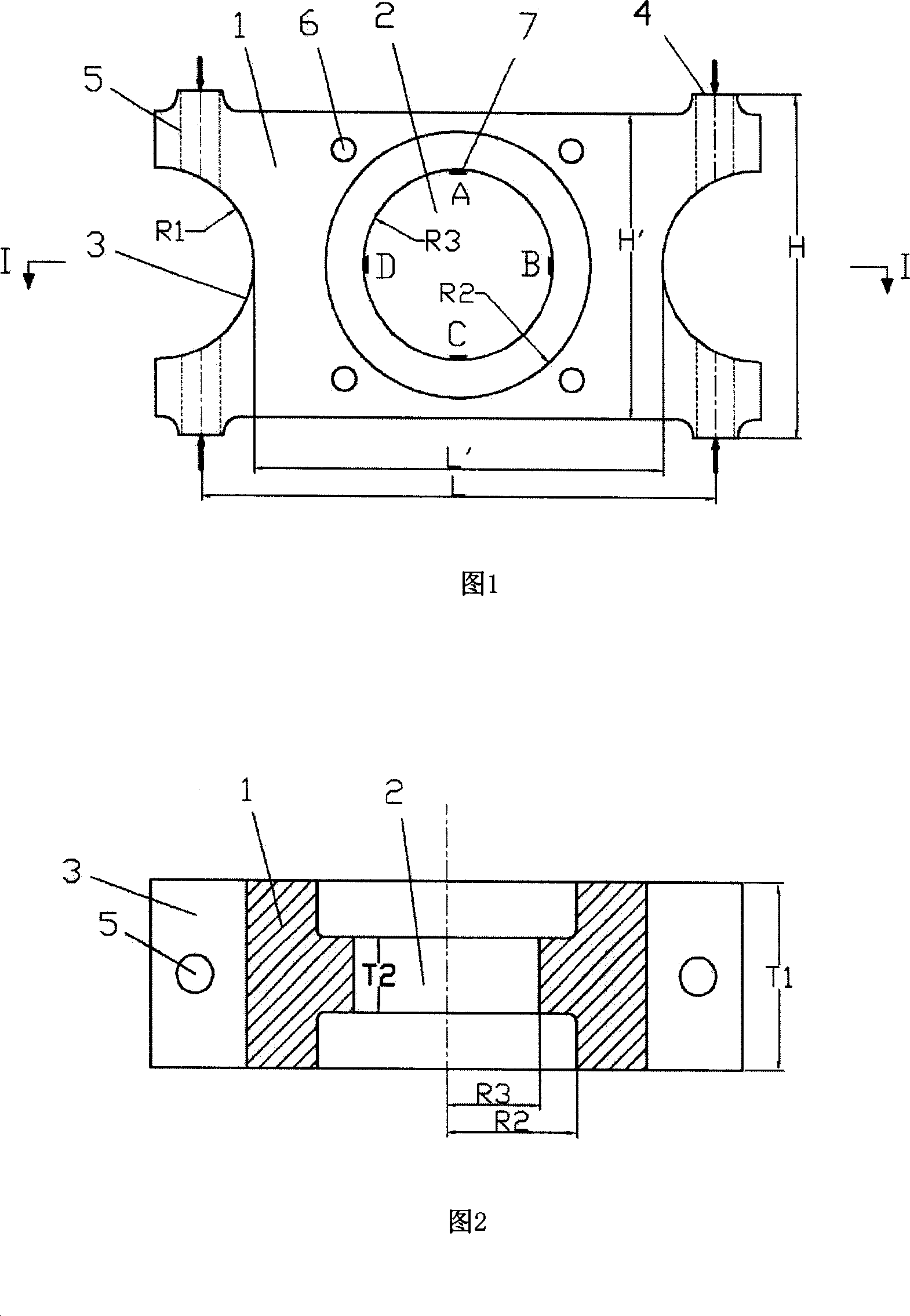

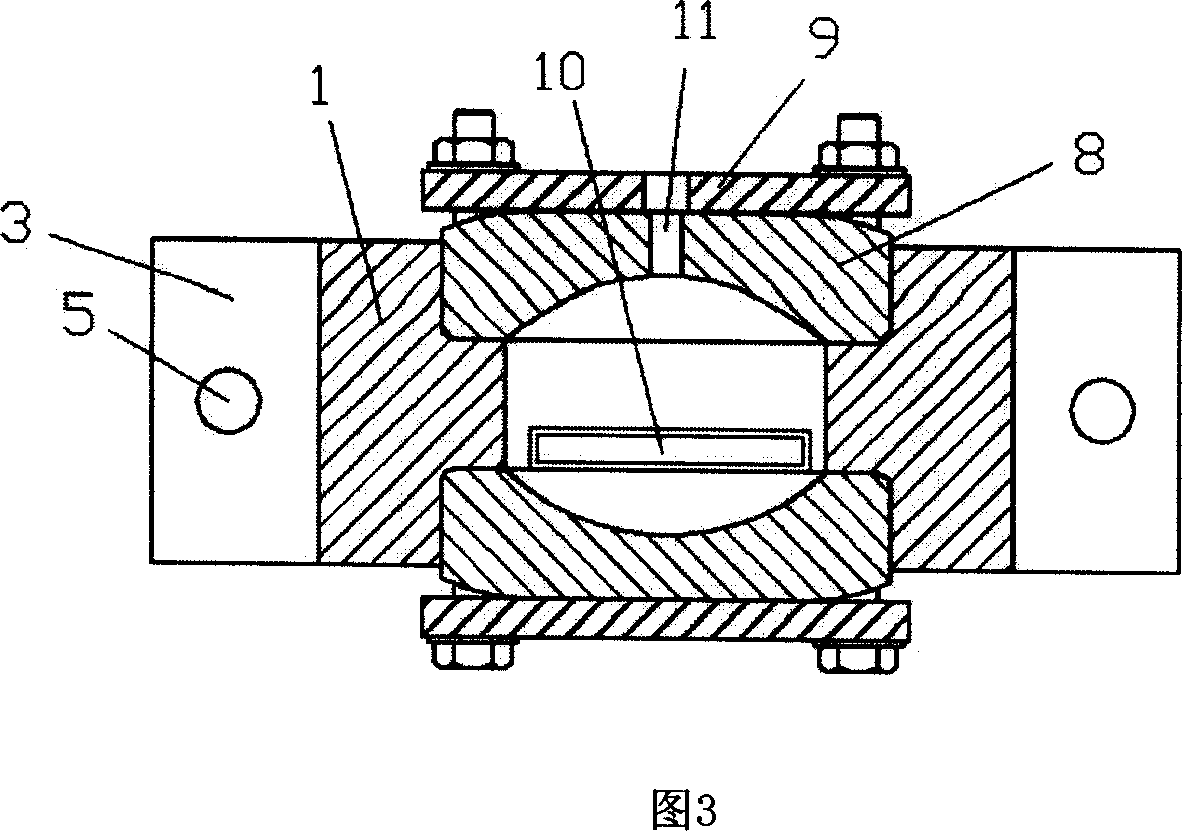

[0017] A beam-ring type force sensor of the present invention, the beam-ring type force sensor when it is not sealed is shown in Figure 1 and Figure 2, and the sensor after sealing is shown in Figure 3.

[0018] As shown in Fig. 1 and Fig. 2, a round hole 2, an arc-shaped notch 3, and a through hole 6 for fixing the pressure plate are opened on the force-bearing element 1, and a threaded hole 5 for fixing the sensor is opened on the force-bearing boss 4; L=136mm, L'=108mm, R1=25mm, R2=35mm, R3=25mm, T1=50mm, T2=20mm. The material is No. 45 steel, the sensitivity obtained by finite element calculation is 35.4με / kN 35.4με / kN, and the stiffness is 7.2×10 8 kN / m.

[0019] The sealing device is shown in Figure 3. Buckle the bowl-shaped rubber cover 8 on both sides of the round hole 2, and then press the pressure plate 9. Use four M6 bolts to fix the pressure plate on the bowl-shaped rubber cover 8 to achieve a waterproof seal. Function, wherein a set of bowl-shaped rubber cover 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com