Temperature measuring device for bottom surface of tin bath of floating glass manufacturing line

A bottom surface, float glass technology, applied in glass production, measuring devices, electrical devices, etc., can solve problems such as unfavorable welding and installation operations of ordinary products, thermocouples cannot be reused, complicated installation and disassembly, etc., to ensure the use of Effects of longevity, bending prevention, and reduction in processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

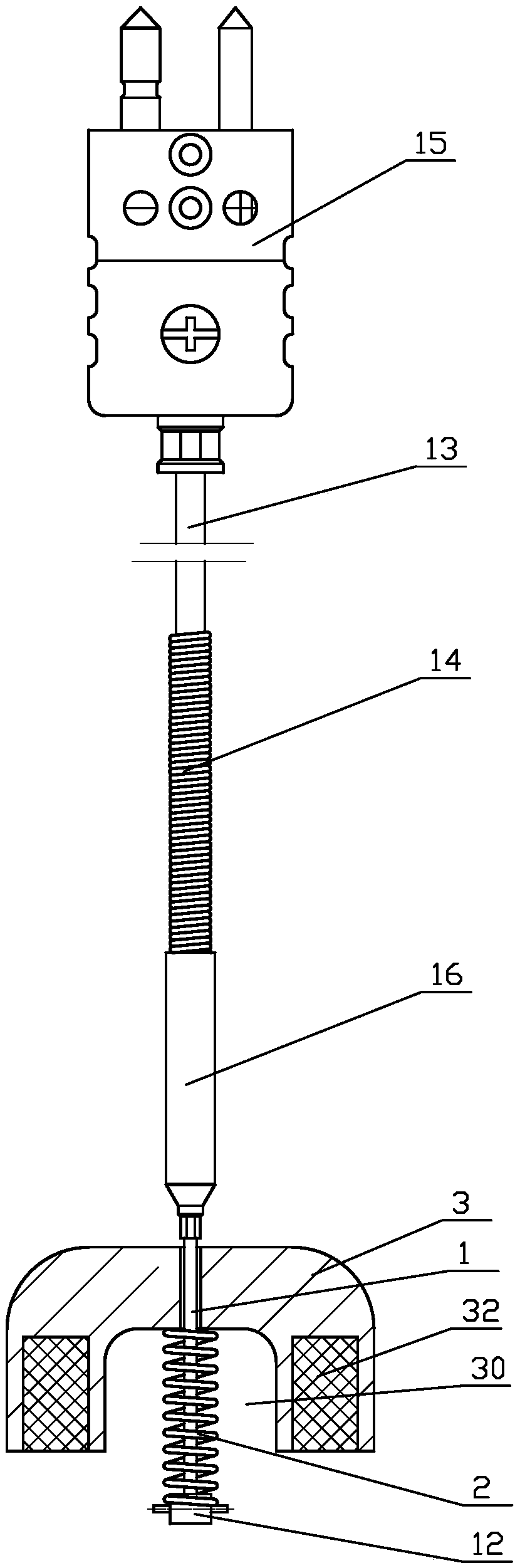

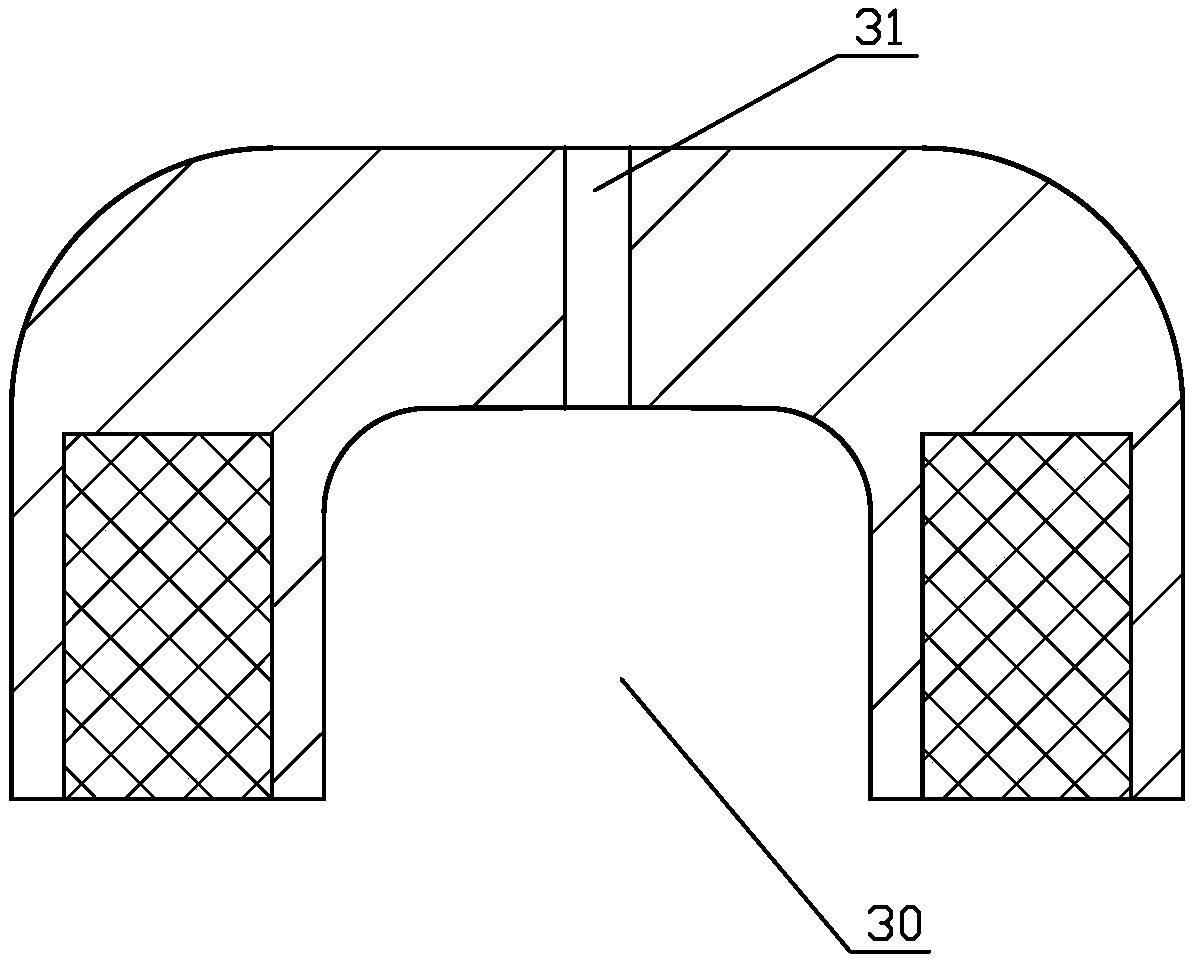

[0030] Such as figure 1 Shown is the temperature measuring device for the bottom surface of the tin bath of the float glass production line disclosed by the present invention, including an armored thermocouple 1, a mounting base 3 and a spring 2; one end surface of the mounting base 3 has a receiving groove 30, Such as figure 2 As shown, in this embodiment, the mounting base 3 has an arched door structure, and the mounting base 3 has a first through hole 31 passing through the receiving groove 30 and the other end surface of the mounting base; the armored thermocouple 1 is placed in the first through hole 31 and its temperature measuring end passes through one end of the receiving groove 30, and the spring 2 is sleeved on the armored thermocouple 1 and is limited between the receiving groove 30 and the between the temperature-measuring ends of the armored thermocouple 1; the mounting seat 3 has a magnetic body 32 on one end surface of the receiving groove 30, and when the ma...

Embodiment 2

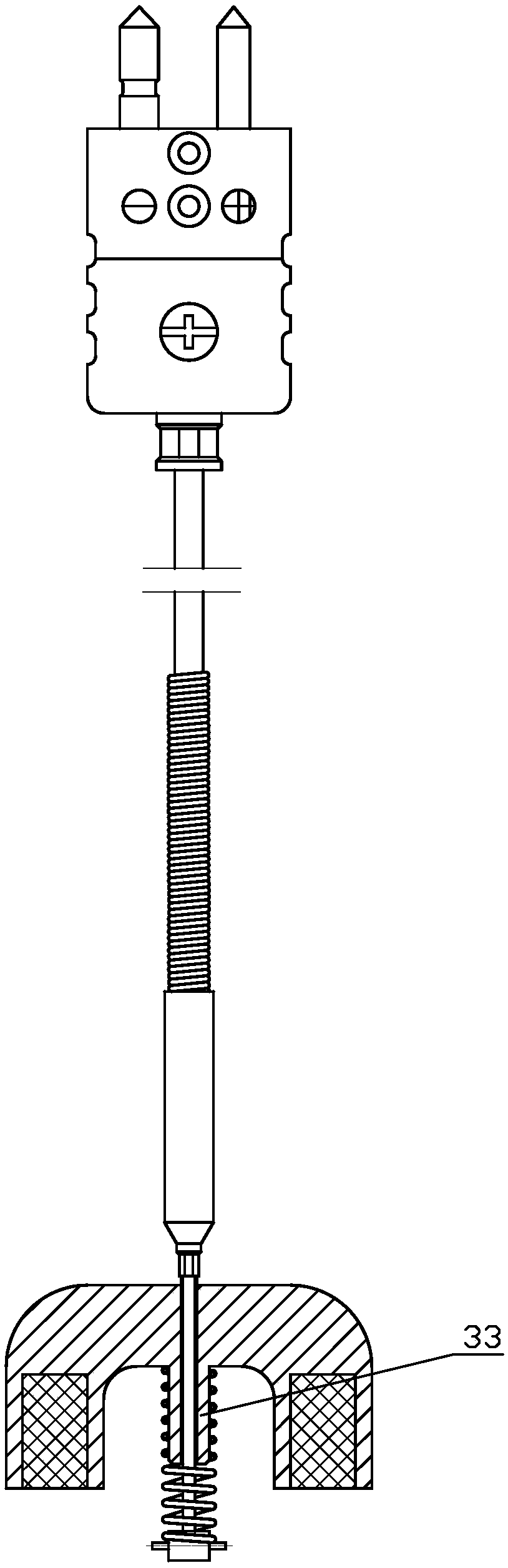

[0035] Such as Figure 4 and Figure 5 Shown is another embodiment of the temperature measuring device for the bottom surface of the tin bath of the float glass production line disclosed by the present invention, in this embodiment, it includes an armored thermocouple 1, a mounting base 3, a spring 2 and a ferrule Part 4; one end surface of the mounting seat 3 has a receiving groove 30, the mounting seat 3 has an arched door structure, and the mounting seat 3 has a first through hole passing through the receiving groove 30 and the other end surface of the mounting seat 31, the ferrule 4 is fixed in the first through hole 31 and one end is placed in the receiving groove 30 to form a guide protrusion 33, the spring 2 is sleeved on the guide protrusion 33, when the spring is compressed , the spring moves along the outer wall of the guide protrusion, the ferrule 4 has a second through hole 40, the armored thermocouple 1 is placed in the second through hole 40, and its measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com