Boiler system adopting burning low-heating-value fuel gas and operation method for boiler system

A low calorific value, gas technology, used in combustion methods, gas fuel burners, burners, etc., can solve problems such as reduced economic benefits, waste of energy, and increased costs, to improve combustion stability, ensure operational safety, and improve thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

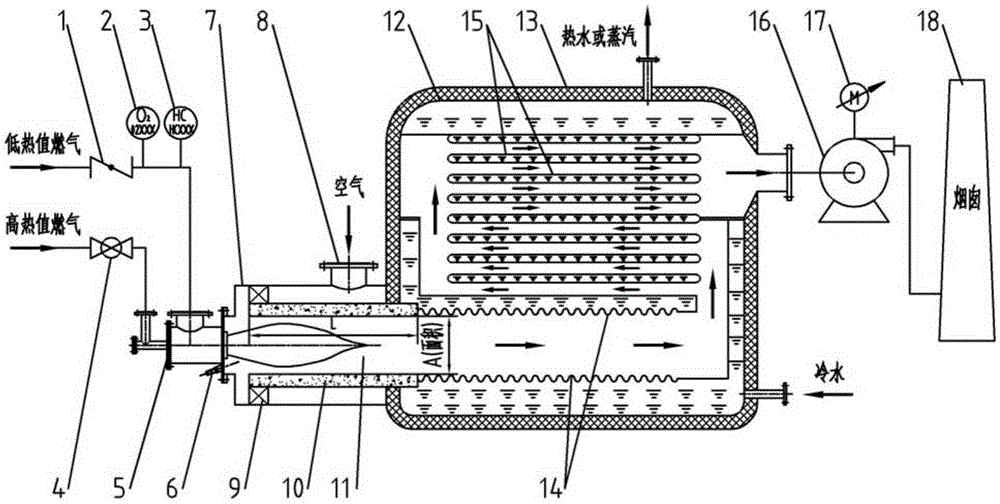

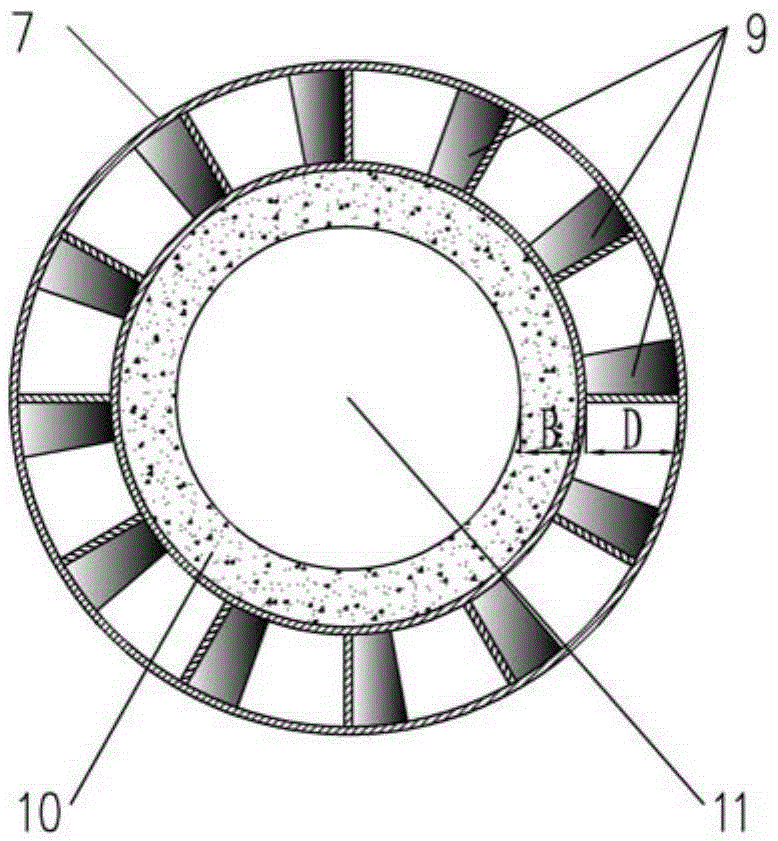

[0025] figure 1 , figure 2 It is an embodiment of the present invention. Boiler system using low calorific value gas, including: low calorific value gas control valve 1, oxygen concentration sensor 2, combustible gas concentration sensor 3, high calorific value gas control valve 4, low calorific value gas burner 5, ultraviolet flame detector 6, combustion Chamber shell 7, air filter 8, swirl blade 9, refractory castable 10, adiabatic combustion chamber 11, boiler body 12, boiler body insulation layer 13, radiation heat exchange surface 14, convection heat exchange surface 15, induced draft fan 16 , induced draft fan frequency conversion controller 17 and chimney 18.

[0026]The low calorific value gas is connected to the low calorific value gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com