Method for reducing emission of carbon dioxide by circulating fluidized bed temperature flue gas circulation oxygen combustion

A circulating fluidized bed and carbon dioxide technology, which is applied in the directions of fluidized bed combustion equipment, combustion methods, and fuel burned in a molten state, can solve the difficulty of heating surface layout, deviation from the optimal operation of circulating fluidized bed boilers, and reduce desulfurization efficiency. and other problems, to achieve the effect of rational utilization, reduction of oxygen production power consumption and CO2 compression power consumption, and improvement of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

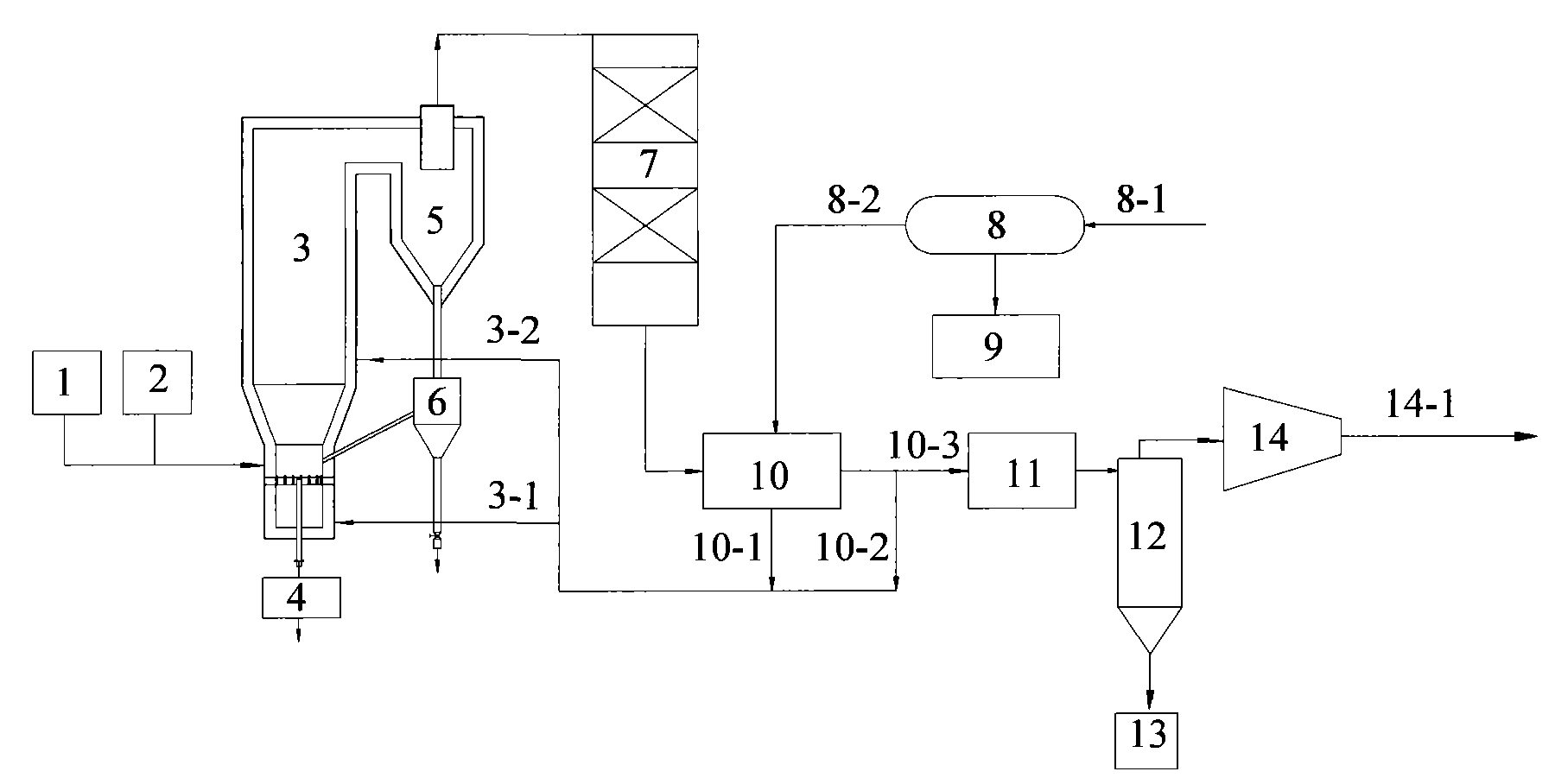

[0018] The fuel and desulfurizer are added to the circulating fluidized bed boiler for combustion, and the flue gas produced is heated by the O produced by the air separation device after heat exchange on the rear heating surface. 2 (concentration is 96.5%-98.5%) to produce warm flue gas at 140°C-150°C, use 30%-70% of the above warm flue gas and O 2 Mixed as an oxidant and sent back to the furnace for cyclic combustion, the remaining warm flue gas is sent to a dust collector to remove dust, and then undergoes multi-stage condensation to remove water and compression to obtain high-concentration CO 2 (greater than 95%), realizing resource utilization or storage. Due to the existence of water vapor in the circulating flue gas in this system, the radiative heat transfer in the furnace is effectively enhanced, and the problem of insufficient convective heat transfer of the circulating fluidized bed oxygen combustion boiler is solved; at the same time, the unburned carbon carried in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com