Liquid high-temperature slag granulation and waste heat recovery device

A waste heat recovery device and slag granulation technology, which is applied in recycling technology, waste heat treatment, and energy efficiency improvement, can solve the problems of high-quality waste heat resource waste of liquid slag, increase heat recovery efficiency, and increase heating area , avoid the effect of toxic gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

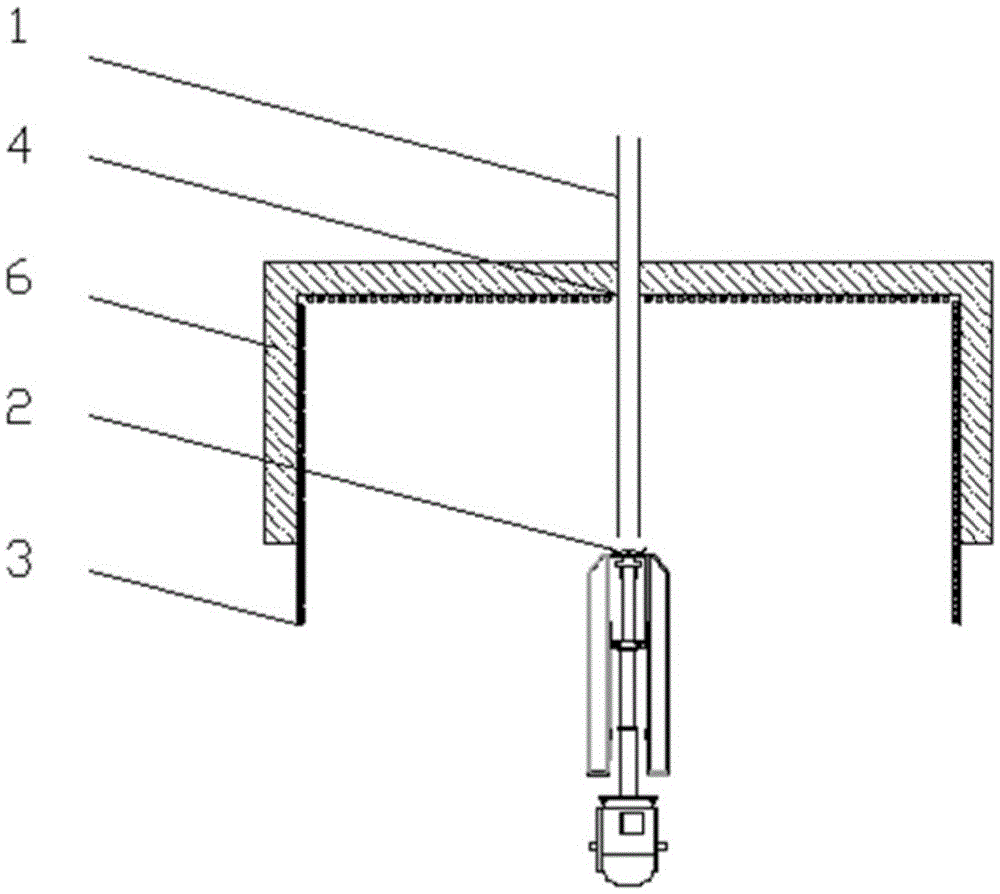

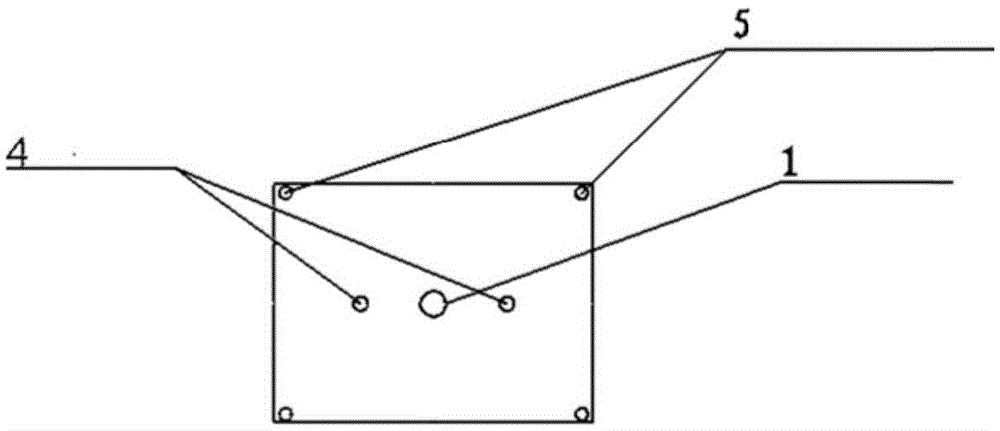

[0025] see figure 1 As shown, a liquid high-temperature slag granulation and waste heat recovery device of the present invention includes a slag falling pipe 1 , a granulation bin 6 and a granulation equipment 2 .

[0026] The granulation bin 6 is in the shape of an inverted box with a rectangular, square or circular cross section, and the top of the granulation bin is flat or domed. The top of the granulation bin 6 is provided with an opening for the slag falling pipe 1 to extend into. The inner wall of the granulation bin 6 is used to absorb the heat exchanging surface 3 emitted by the granulation.

[0027] A granulation device 2 is arranged directly below the slag falling pipe 1 .

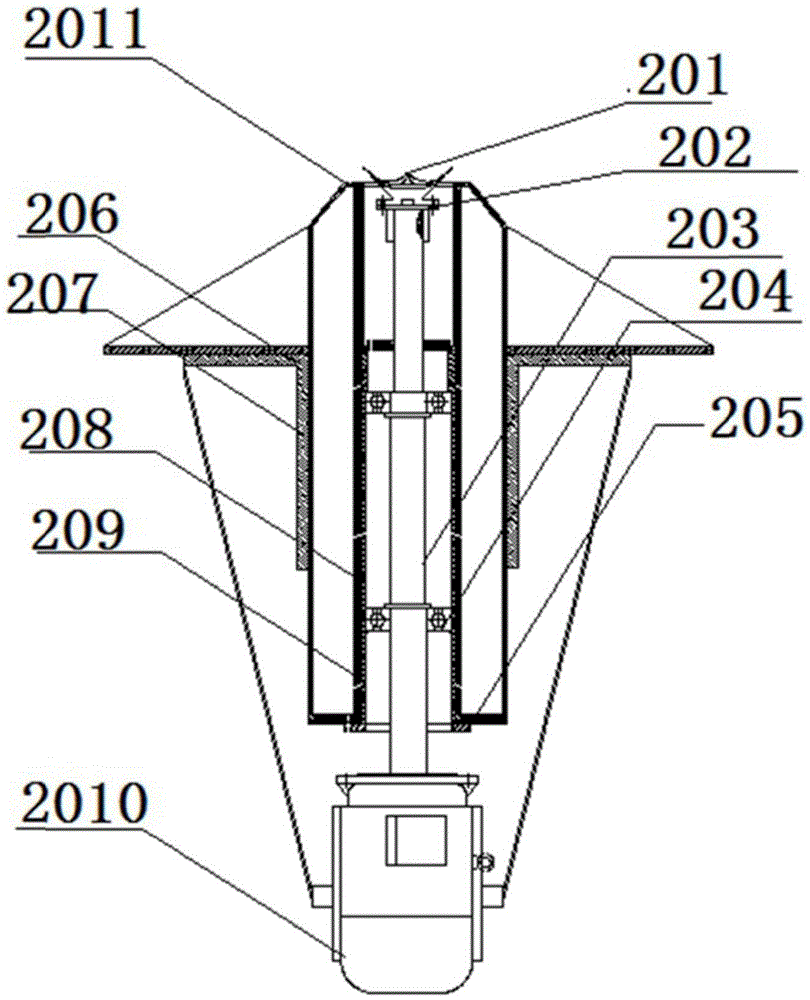

[0028] The high temperature liquid slag granulation system 2 includes a granulator 201, a granulator connecting part, a granulator driving part, an air supply part and auxiliary devices.

[0029] The granulator 201 is disc-shaped or cup-shaped, and a guide cone is set in the center of the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com