Integral condensing boiler

A condensing boiler, integrated technology, applied in fluid heaters, energy-saving heating/cooling, air heaters, etc., can solve the problems of poor film condensation heat transfer effect, tearing condensate film, poor condensation heat transfer conditions, etc. , to achieve the effects of reducing pollutant emissions, enhancing convective heat transfer, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings.

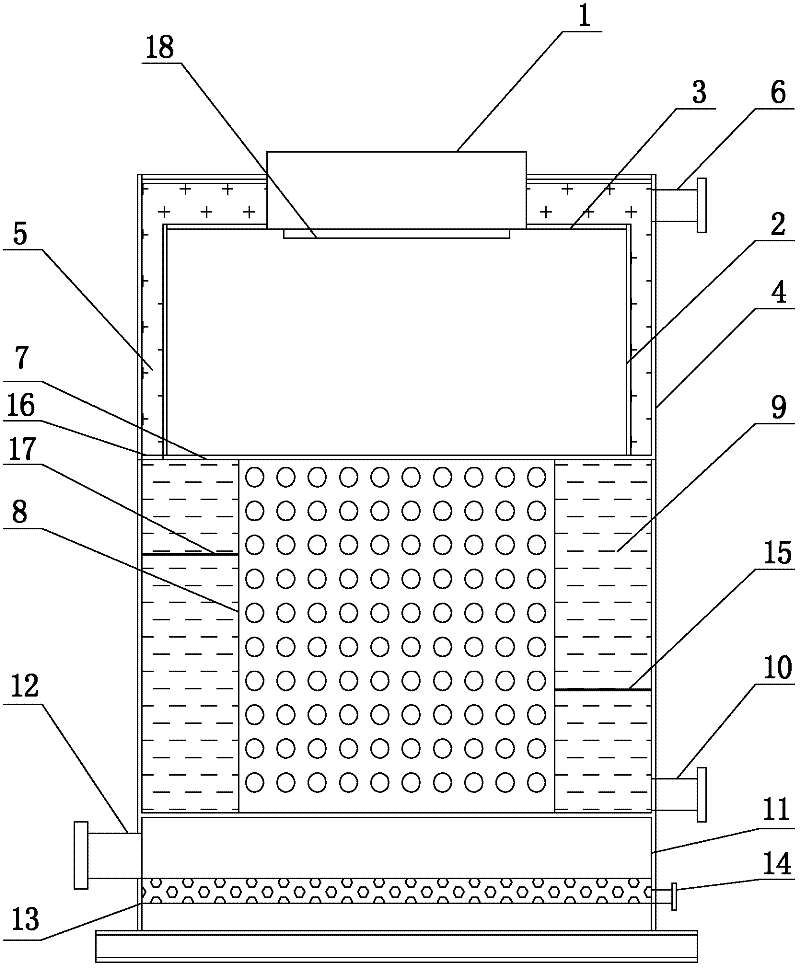

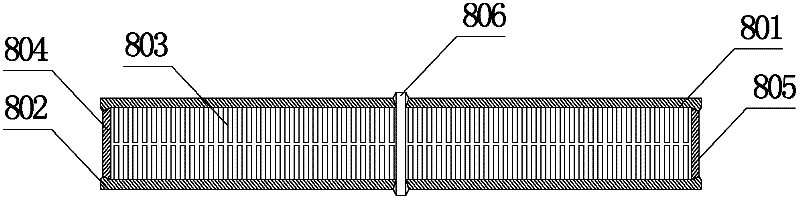

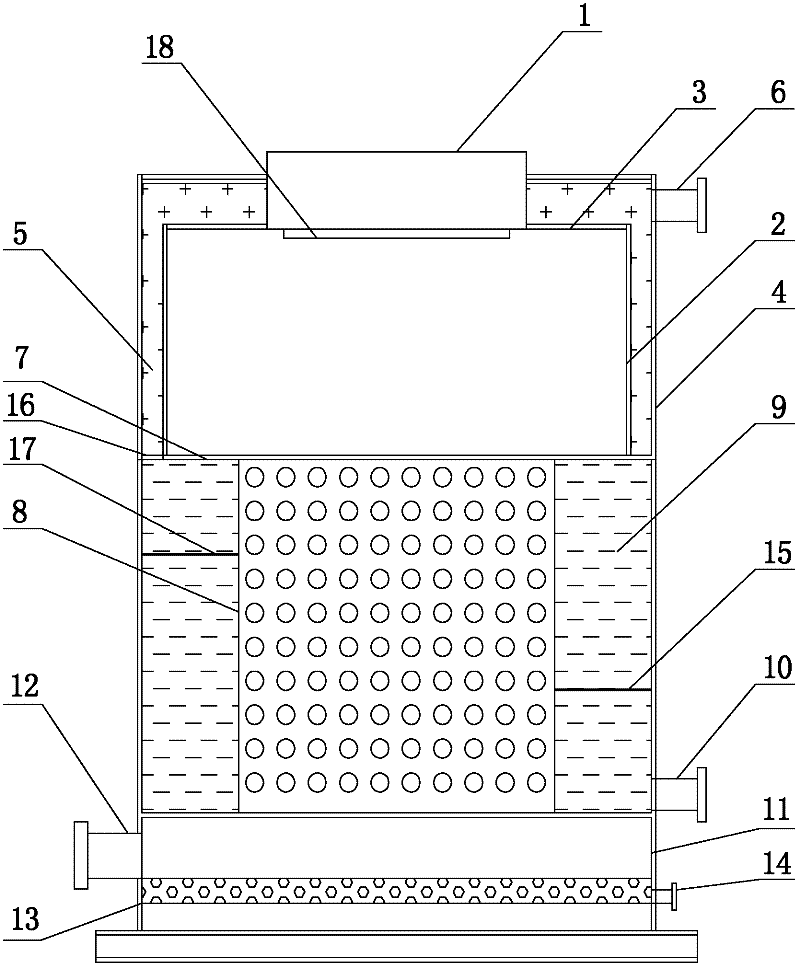

[0019] Such as figure 1 As shown, the integral condensing boiler includes a condensing boiler surrounded by an outer shell 4. Above the condensing boiler is a furnace 2, and a fully premixed flameless burner 1 is placed on the upper top plate 3 of the furnace 2. The furnace A water jacket 5 is covered between the outer wall of the shell 2 and the inner wall of the shell 4. The lower bottom plate 7 at the bottom of the furnace 2 is connected to the top of more than one plate-fin heat transfer element 8 for overall convection and condensation heat exchange. The bottom of the finned heat transfer element 8 is in communication with the top of the turning smoke chamber 11, and the condensate neutralization treatment device 13 with the condensate discharge pipe 14 is arranged under the turning smoke chamber 11, and the outer side of the turning smoke chamber 11 has T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com