Casting waste heat recycling device based on radiant heat exchange

A waste heat recovery and radiation heat exchange technology, applied in waste heat treatment, furnace components, lighting and heating equipment, etc., can solve the problems of low heat recovery rate and efficiency, low radiation coefficient, etc., and achieve easy maintenance, safe and reliable operation, long life long effect

Active Publication Date: 2017-07-07

HEBEI UNIV OF TECH

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This patent realizes waste heat recovery of sand shell castings in a discontinuous manner, but due to the low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

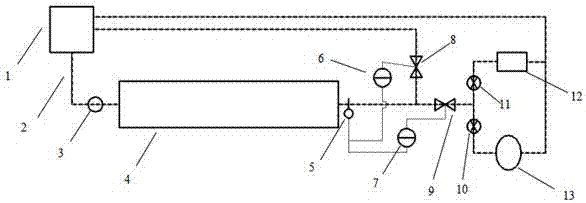

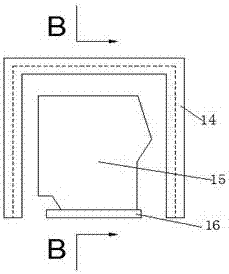

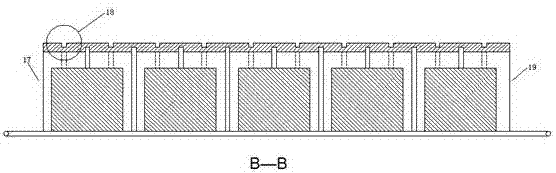

The invention relates to a casting waste heat recycling device based on radiant heat exchange. The casting waste heat recycling device comprises a steel caterpillar band, an aluminum waste heat recycling device, a water storage box, a circulating water pump, a circulating water pipe, a temperature sensor, a temperature controller, solenoid valves, an absorption refrigeration device and a heating pipe net device; the aluminum waste heat recycling device with the model cross section is arranged on the steel caterpillar band; a water outlet of the water storage box is connected with a water inlet of the waste heat recycling device through the circulating water pipe, and the circulating water pump is arranged on the circulating water pipe; a water outlet of the waste heat recycling device is provided with the temperature sensor and the temperature controller, and the temperature controller is used for controlling opening and closing of the two solenoid valves; and hot water pipes behind the solenoid valves are connected with the water storage box, the absorption refrigeration device and the heating pipe net device. According to the casting waste heat recycling device, while high temperature casting waste heat is recycled, the internal structure character of a casting is not influenced. The overall device is fewer in motion part, safe, reliable, long in service life, easy to maintain and environment-friendly, and continuous recovering of the high temperature casting waste heat under intermittent production of small and medium size casting enterprises can be achieved.

Description

technical field [0001] The invention relates to the technical field of waste heat recovery and utilization, in particular to a high-temperature casting waste heat recovery and utilization device based on radiation heat exchange, specifically a device for effectively recovering and utilizing the waste heat of exposed high-temperature castings after sand falling. Background technique [0002] With the rapid development of society, energy conservation and emission reduction have been paid more and more attention, and the recovery and utilization of industrial waste heat has always been the focus of energy conservation and emission reduction. At present, the high, medium and low-grade waste heat recovery and utilization technologies involved in continuous production enterprises are basically mature, but in intermittent production industries such as foundry industry, the development and promotion of waste heat recovery and utilization technologies still need to be strengthened. A...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D30/00F27D17/00

CPCB22D30/00F27D17/004Y02P10/25

Inventor 刘联胜邸高雷

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com