Descaling system for long metal materials

A descaling system and long product technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem that the medium cannot be recycled efficiently and stably, and achieve continuous recycling, save loss, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

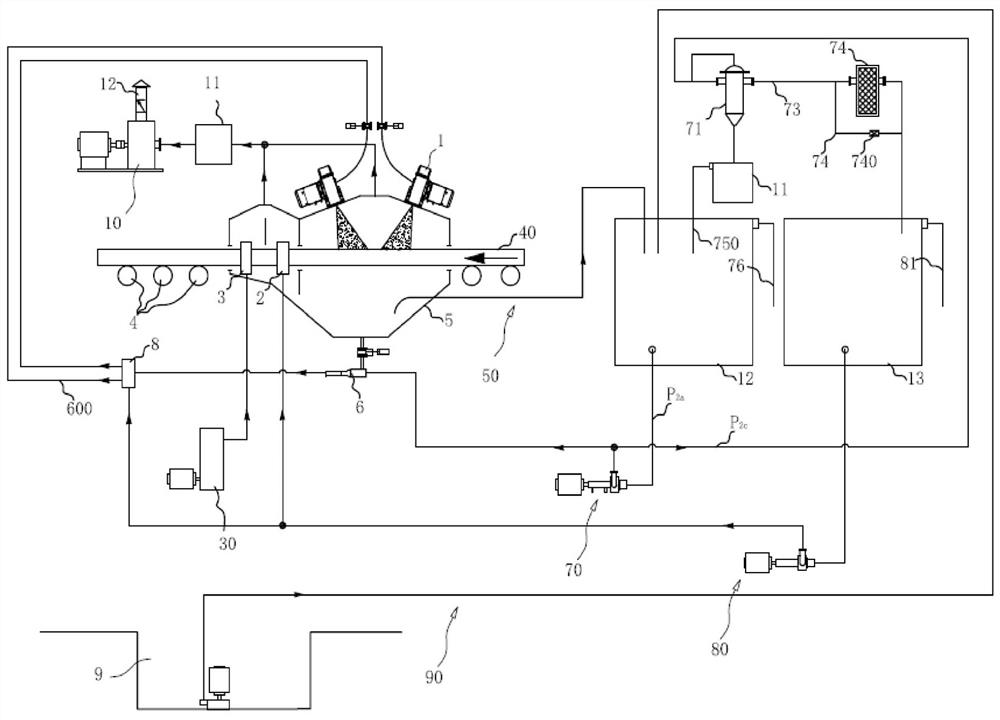

[0035] Such as figure 1 As shown, the descaling system for metal long products includes a descaling device, a washing device, a drying device and a circulation system. The workpiece enters the descaling device for descaling, then enters the rinsing device for surface cleaning, and finally enters the drying device for drying. dry to complete the entire process. The descaling device includes a fluidizer 1. In this embodiment, there are two fluidizers 1, and the two fluidizers 1 are arranged symmetrically above the workpiece. The ejectors 1 have their own independent drive motors for connection and transmission. The transmission mode is not limited to direct drive, and belt drive, gearbox drive or coupling drive can also be used. The ejector 1 sprays a mixture of abrasives and water to clean the workpiece. Surface scales.

[0036] The flushing device includes a flushing ring 2, which is supplied with water by a circulation system, and the inner wall of the flushing ring 2 is pr...

Embodiment 2

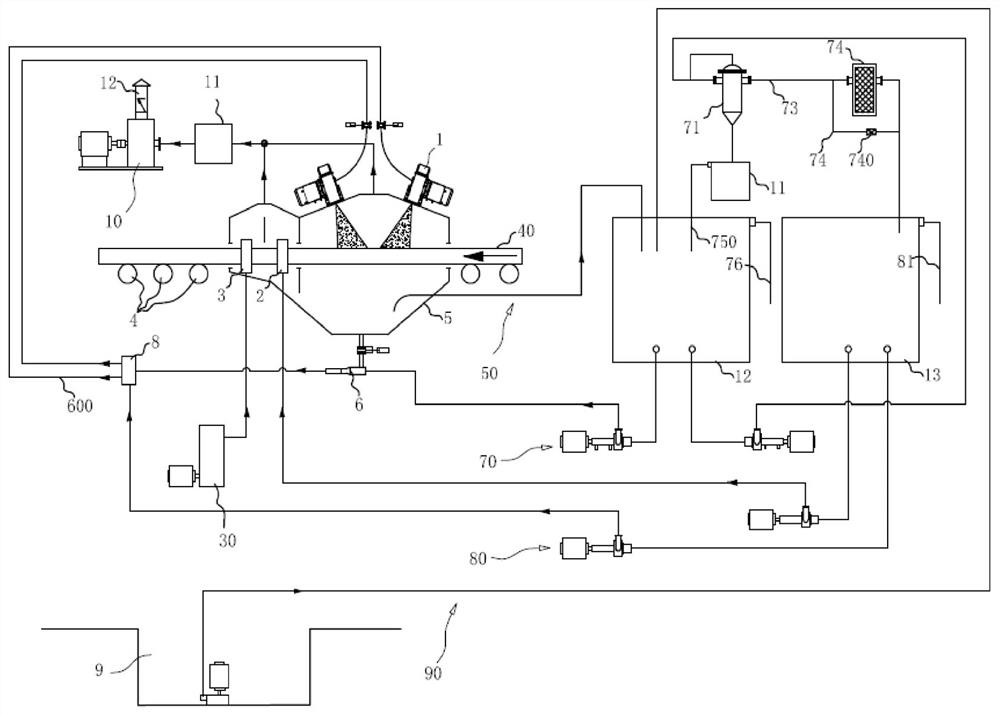

[0050] The difference between this embodiment and Embodiment 1 is that, as figure 2 As shown, there are two sets of second delivery pipe sets 70, one set of second delivery pipe sets 70 is connected to the water inlet end of the pumping device, and the other set of second delivery pipe sets 70 is connected to the inlet end of the filtration system. The third delivery pipe group 80 is provided with two groups, one group of the third delivery pipe group 80 is connected to the flushing device, and the other group of the third delivery pipe group 80 is connected to the mortar distributor 60 . That is to say, two sets of second conveying pipe sets 70 supply water to the pumping device and the filtration system respectively, and two sets of third conveying pipe sets 80 respectively supply water to the flushing device and the mortar distributor 60, so that the water supply volume is easier to control and the production efficiency is higher .

Embodiment 3

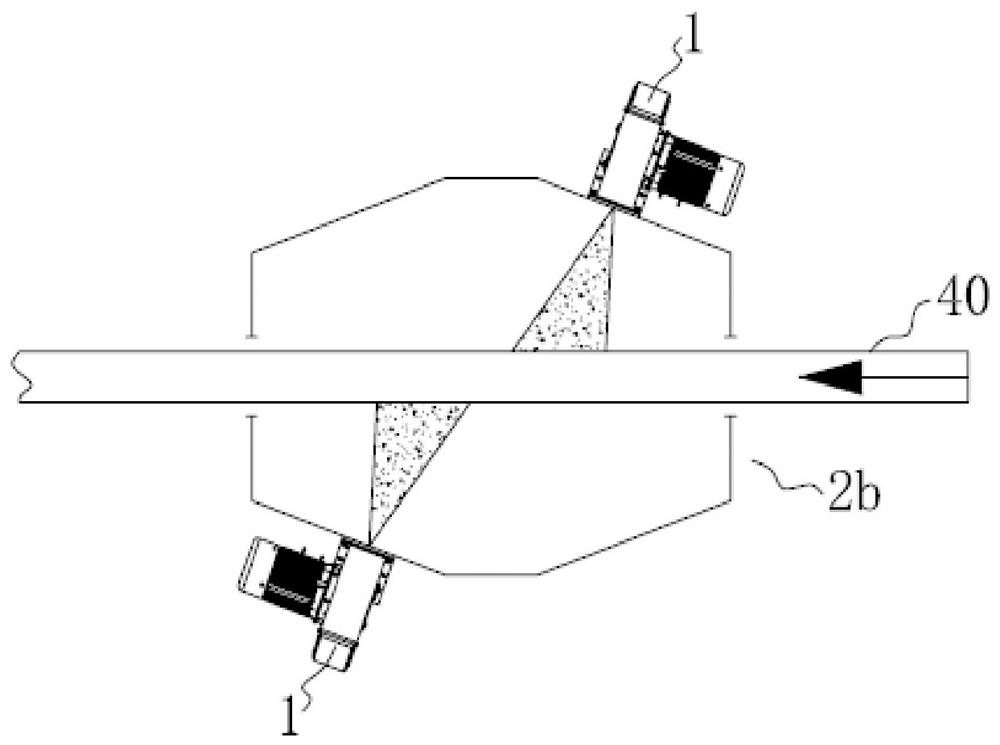

[0052] The difference between this embodiment and Embodiment 1 is that, as image 3 As shown, there are two jets 1, and the two jets 1 are arranged symmetrically above and below the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com