Method for recovering n-butane from tail gas of maleic anhydride preparation by butane method

A recovery method and technology for n-butane, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problem of adding precision gas component analysis, control equipment, n-butane is not recovered or partially recovered, and increases the difficulty of operation. and equipment investment to achieve excellent application value, continuous and efficient recovery, and avoid adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

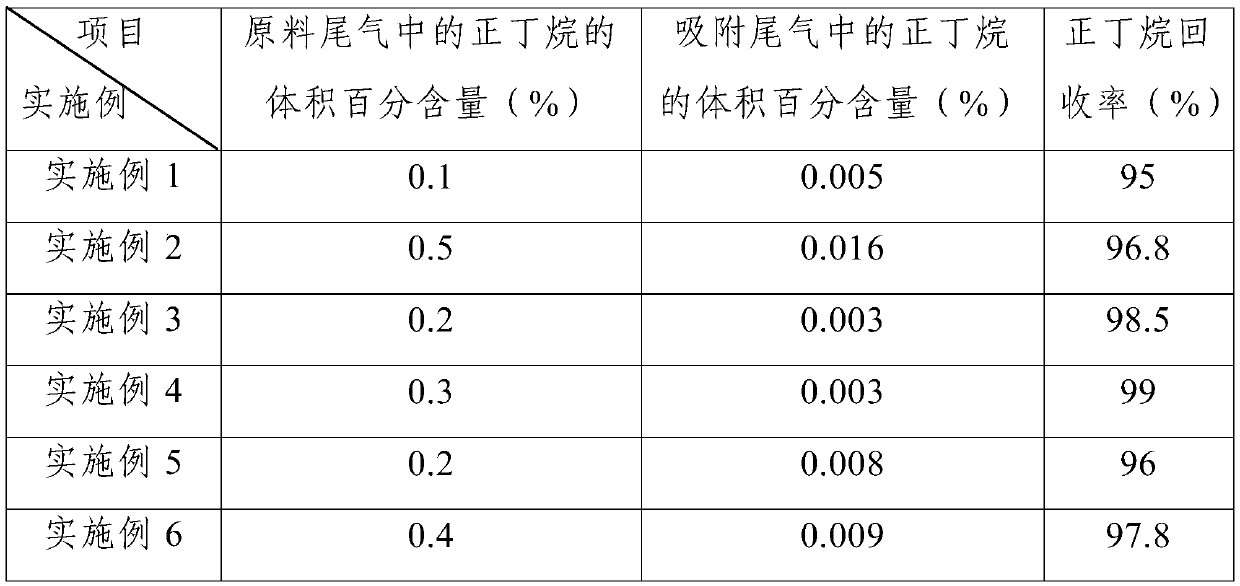

Embodiment 1

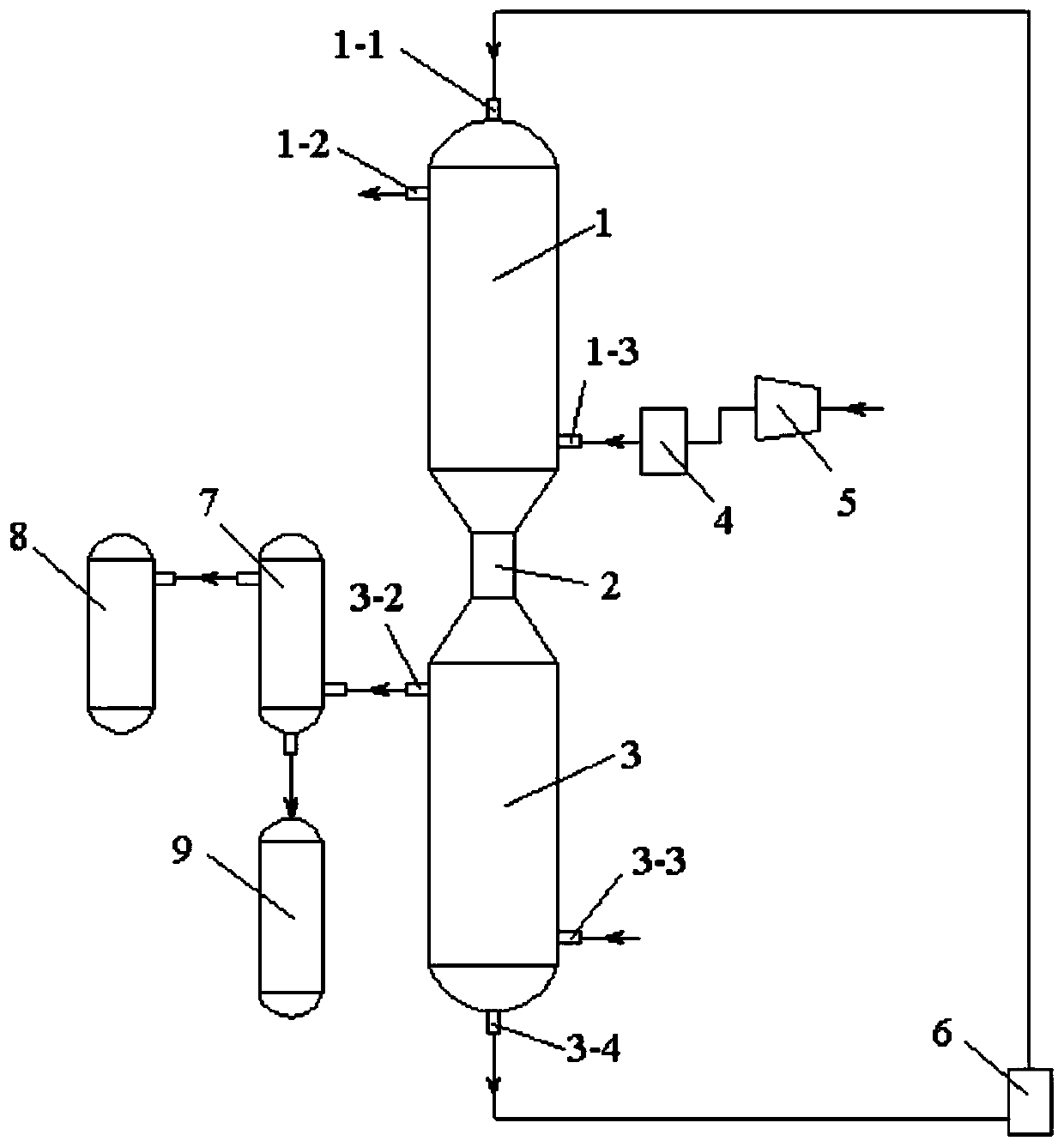

[0044] The method of the present embodiment comprises the following steps:

[0045] Step 1, adopt the gas booster 5 to pressurize the maleic anhydride tail gas produced by the butane process to 100kPa and send it into the spray scrubber 4 for washing and spraying; the maleic anhydride tail gas produced by the butane process is composed of the following volume percentage Gas composition: 0.1% of n-butane, 2% of carbon monoxide, 2% of carbon dioxide, 8% of oxygen, and the balance is nitrogen; the water temperature used for the washing and spraying is 10°C;

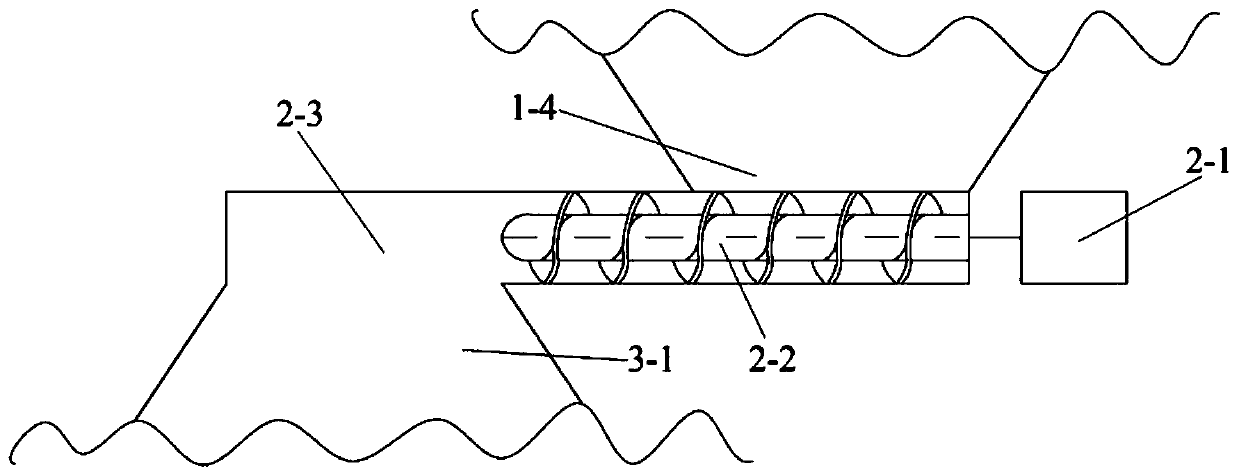

[0046] Step 2. Send the maleic anhydride tail gas produced by the butane method after washing and spraying in step 1 into the adsorber 1 through the first air inlet 1-3 and enter the adsorber 1 through the first feed port 1-1. The adsorbent is selectively adsorbed to obtain the adsorbent for adsorbing n-butane and the adsorption tail gas, and then the adsorption tail gas is discharged through the first gas outlet 1-2 and the...

Embodiment 2

[0051] The method of the present embodiment comprises the following steps:

[0052] Step 1, adopt the gas booster 5 to pressurize the maleic anhydride tail gas produced by the butane method to 500kPa and send it into the spray scrubber 4 for washing and spraying; the maleic anhydride tail gas produced by the butane method is composed of the following volume percentage Gas composition: 0.5% of n-butane, 0.5% of carbon monoxide, 0.5% of carbon dioxide, 20% of oxygen, and nitrogen as the balance; the water temperature used for the washing and spraying is 50°C;

[0053] Step 2. Send the maleic anhydride tail gas produced by the butane method after washing and spraying in step 1 into the adsorber 1 through the first air inlet 1-3 and enter the adsorber 1 through the first feed port 1-1. The adsorbent is selectively adsorbed to obtain the adsorbent for adsorbing n-butane and the adsorption tail gas, and then the adsorption tail gas is discharged through the first gas outlet 1-2 and ...

Embodiment 3

[0058] The method of the present embodiment comprises the following steps:

[0059] Step 1, adopt the gas booster 5 to pressurize the maleic anhydride tail gas produced by the butane process to 250kPa and send it into the spray scrubber 4 for washing and spraying; the maleic anhydride tail gas produced by the butane process is composed of the following volume percentage Gas composition: 0.2% of n-butane, 1.1% of carbon monoxide, 1.0% of carbon dioxide, 14% of oxygen, and the balance being nitrogen; the water temperature used for the washing and spraying is 15°C;

[0060] Step 2. Send the maleic anhydride tail gas produced by the butane method after washing and spraying in step 1 into the adsorber 1 through the first air inlet 1-3 and enter the adsorber 1 through the first feed port 1-1. The adsorbent is selectively adsorbed to obtain the adsorbent for adsorbing n-butane and the adsorbed tail gas; the adsorbent flows from top to bottom in the adsorber 1 in a plug flow state, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com