A Device for Adjusting the Axial Angle of an End Beam Traveling Wheel

A technology for adjusting devices and wheels, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of end beam wheel deviation, difficult adjustment, long cycle, etc., to achieve the effect of controlling quality, reducing welding workload, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

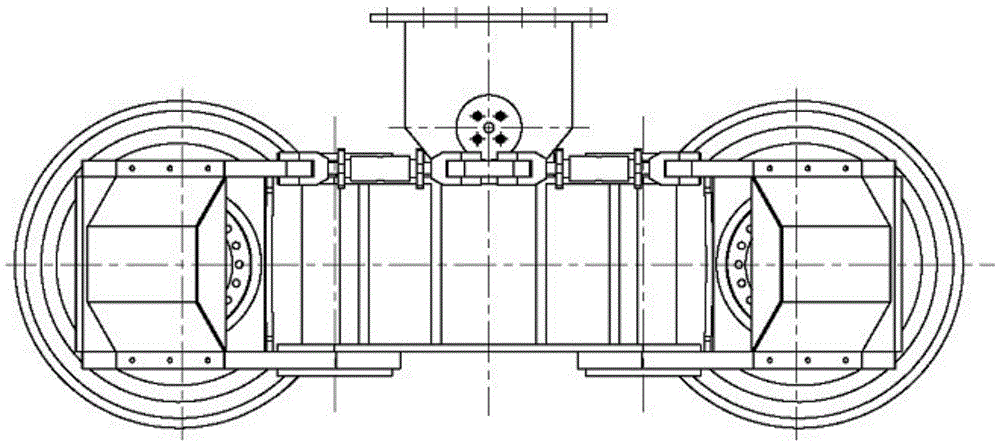

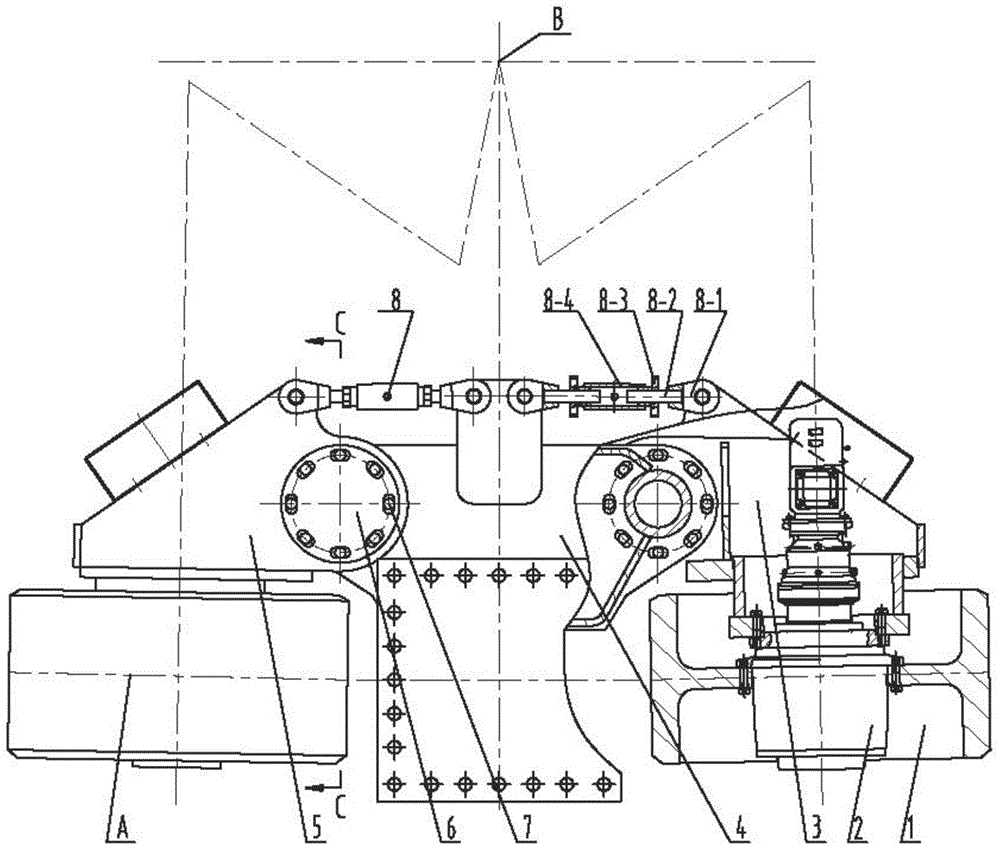

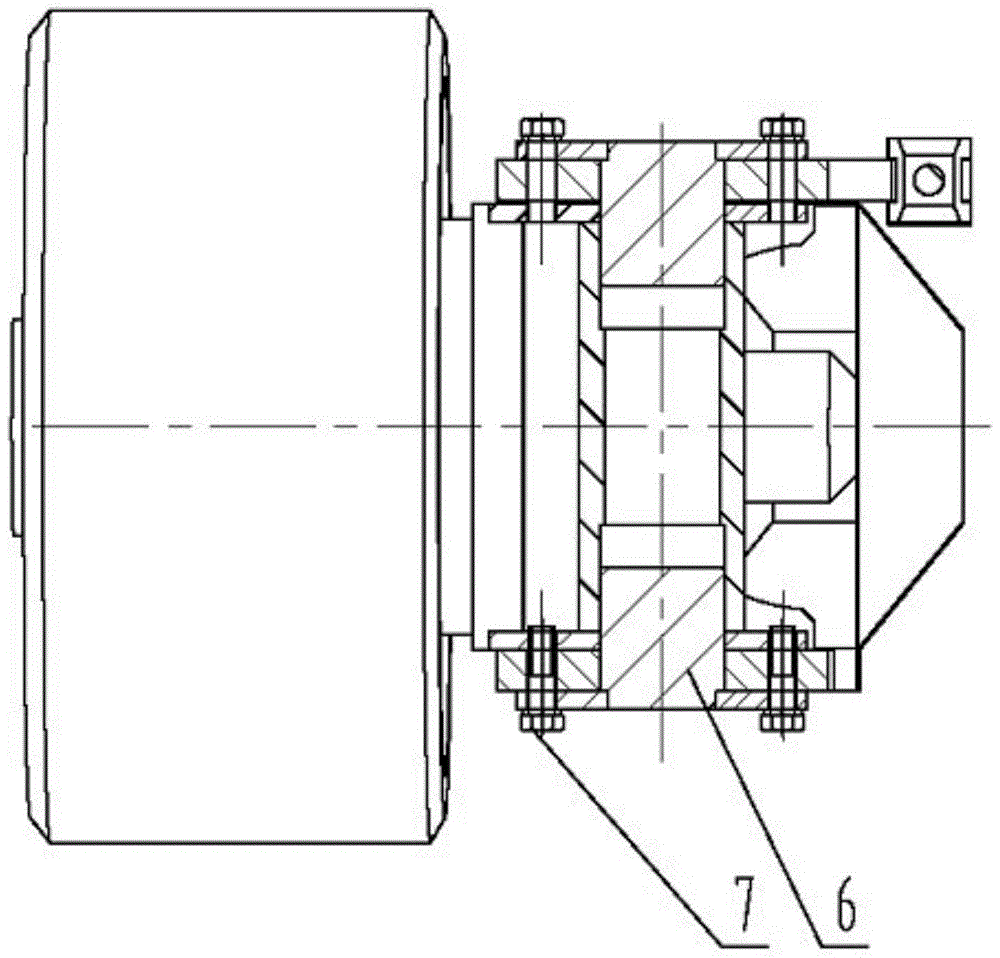

[0018] Referring to the accompanying drawings, a device for adjusting the axial angle of an end beam traveling wheel includes a wheel 1, a drive unit 2, a left wheel frame 3, a trolley frame 4, a right wheel frame 5, a pin shaft 6, a connecting bolt 7, and an adjustment device Combination 8, the trolley frame 4 is connected with the left wheel frame 3 and the right wheel frame 5 using hinge shafts, and the trolley frame 4 and the left wheel frame 3 and the right wheel frame 5 pass through the pin shaft 6 at the hinge point with connecting bolts 7 connection, the wheel 1 is installed on the drive unit 2 and connected with the left wheel frame 3 and the right wheel frame 5, two sets of wheels 1 and two sets of drive units 2 are respectively connected with the left wheel frame 3 and the right wheel frame 5, and the left wheel frame 3 1. The right wheel frame 5 is connected with the trolley frame 4 through the hinge shaft 6 and the connecting bolt 7, one side of the adjustment devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com