Node for connecting concrete-filled steel tube column and external wrapping U-shaped steel concrete composite beam

A technology for steel pipe concrete columns and connection nodes, which is applied in building components, earthquake resistance, construction, etc., and can solve problems such as limited scope of application, large number of openings, and increased construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

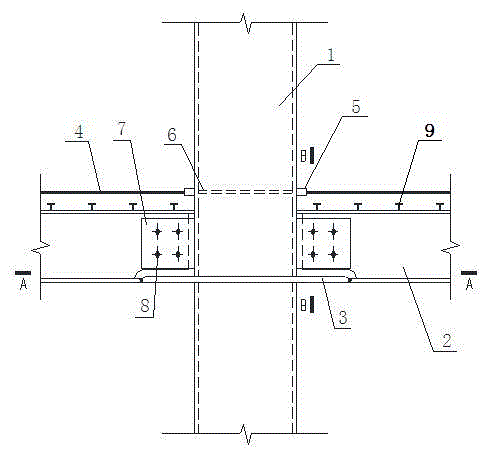

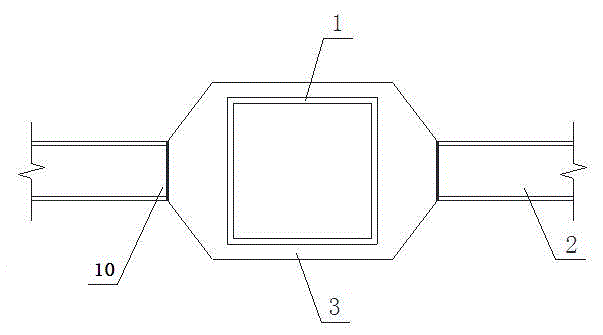

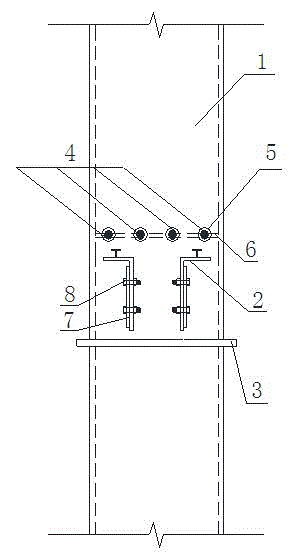

[0050] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0051] Limb cutting: refers to cutting off a part of the bottom plate of the U-shaped steel as required.

[0052] Composite beam: refers to the abbreviation of U-shaped steel concrete composite beam.

[0053] High-strength bolts: refer to high-strength bolts, which are a standard part. In general, high-strength bolts can withstand a larger load than ordinary bolts of the same specification.

[0054] A connection node between a steel pipe concrete column and an outsourcing U-shaped steel concrete composite beam, as shown in the figure, it includes an outer ring plate 3 and a horizontal stiffening plate 6, and the horizontal stiffening plate 6 is provided with pouring holes 12 and ventilation holes 11, The outer ring plate 3 is welded to the outer side of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com