Construction technology for stretching notch by cast-in-situ prestress box beam

A construction process and prestressing technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of lack of reserved structural steel bars, influence of construction period, improper construction method of blocking, etc., and it is easy to guarantee and improve the pouring quality. The effect of installation accuracy and method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

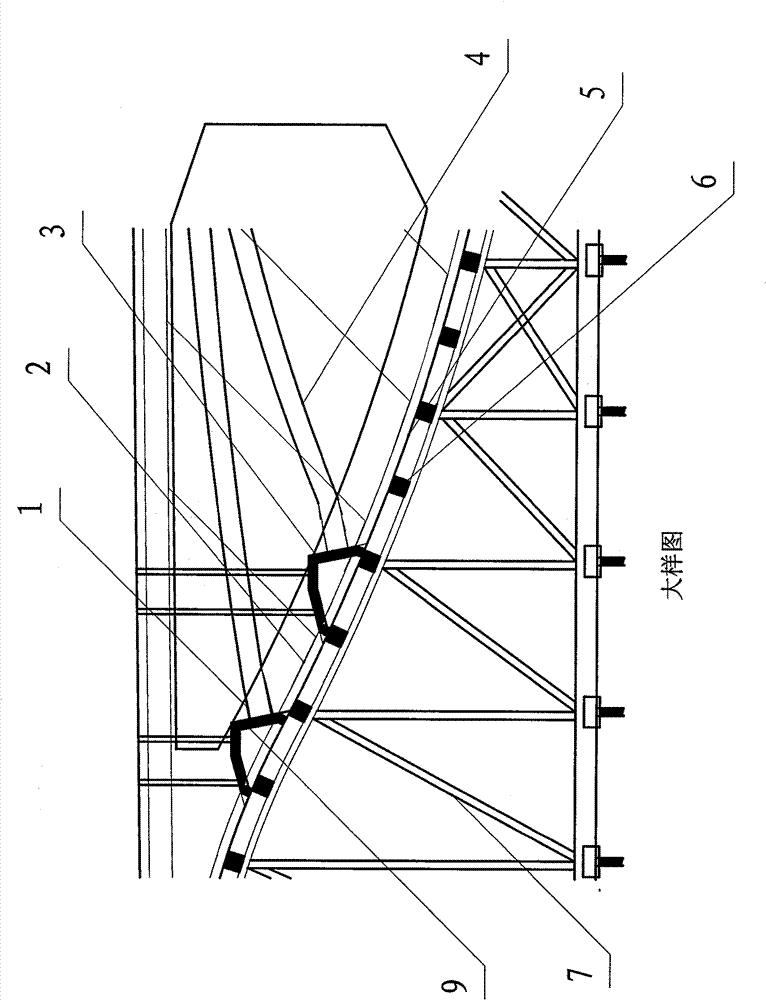

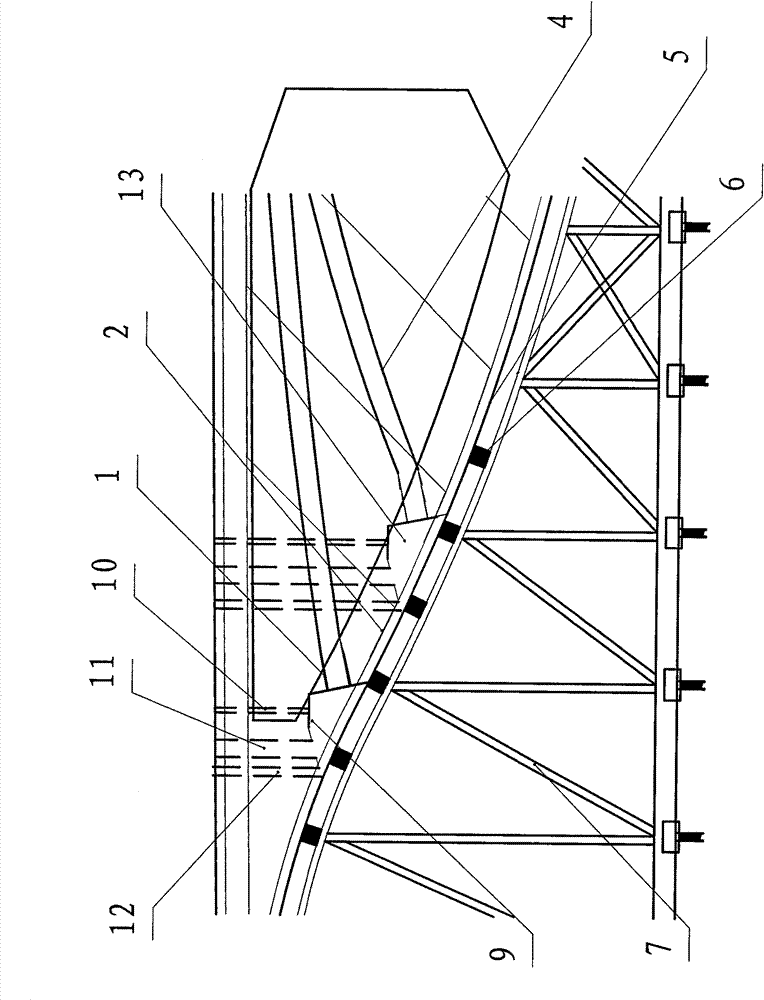

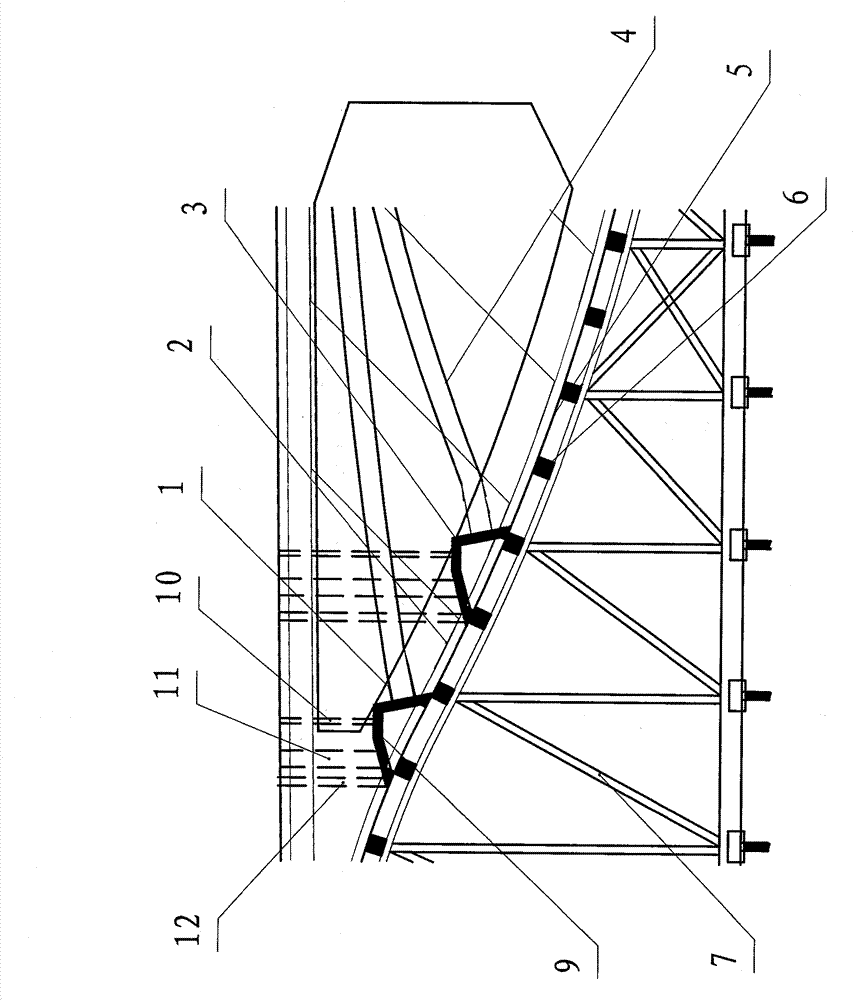

[0033] Example: see Figure 3-Figure 6

[0034] A construction process for the tension notch of a cast-in-place prestressed box girder, including the following four parts

[0035] The first step: notch formwork support

[0036] While bundling the steel bars of the box girder, fix the supporting frame of the notch formwork to the bottom form of the box girder, install the notch formwork on its supporting frame, install the fixed anchors on the notch formwork, and then carry out Installation of prestressed bellows and prestressed steel bars;

[0037] Step 2: Reserve holes for tensioning equipment suspension, secondary irrigation holes and vent holes

[0038] Use PVC pipes to reserve holes for tensioning equipment suspension, secondary pouring holes, and vent holes between the lower notch and the top surface of the box girder. The PVC pipes should avoid prestressed corrugated pipes. The vent holes mentioned At the highest point of the notch formwork; then concrete pouring of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com