Steel-concrete composite structure switching section for wind power tower

A technology of combined structure and transition section, which is applied in basic structure engineering, installation/support of wind turbine configuration, construction, etc., can solve the problem of poor positioning accuracy of high-strength anchor bolt holes, difficult anchor bolt connection construction, and easy formation of cavities in concrete. and other problems, to achieve the effect of easier guarantee of pouring quality, convenient pouring process and improved ultimate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention.

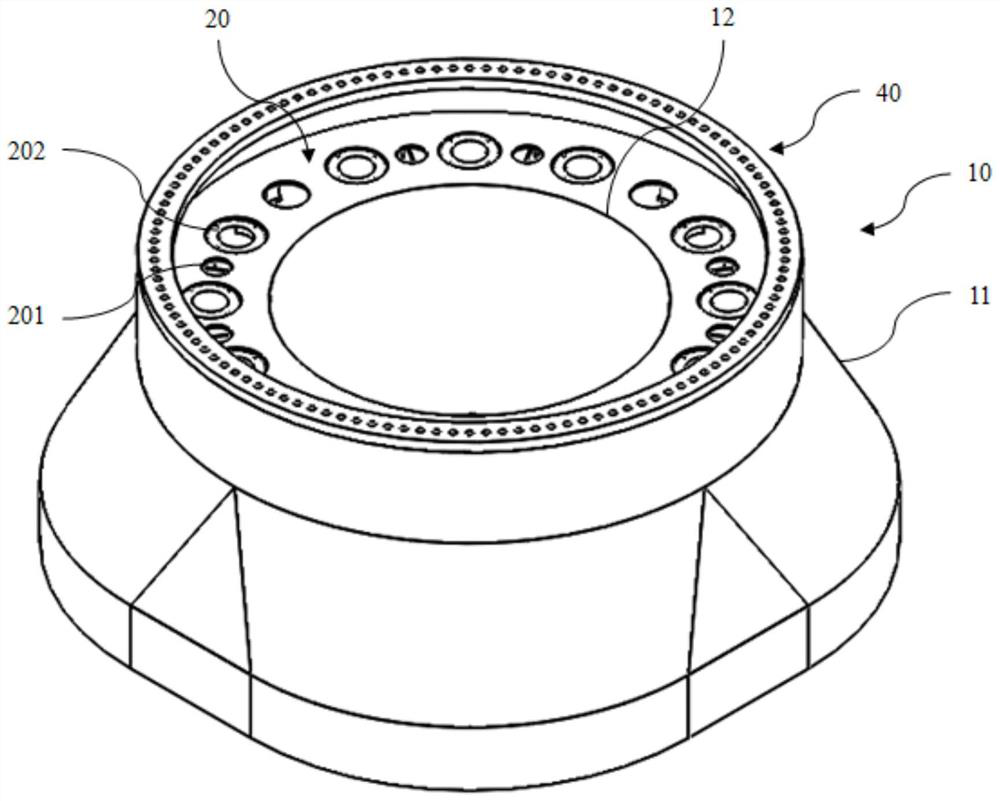

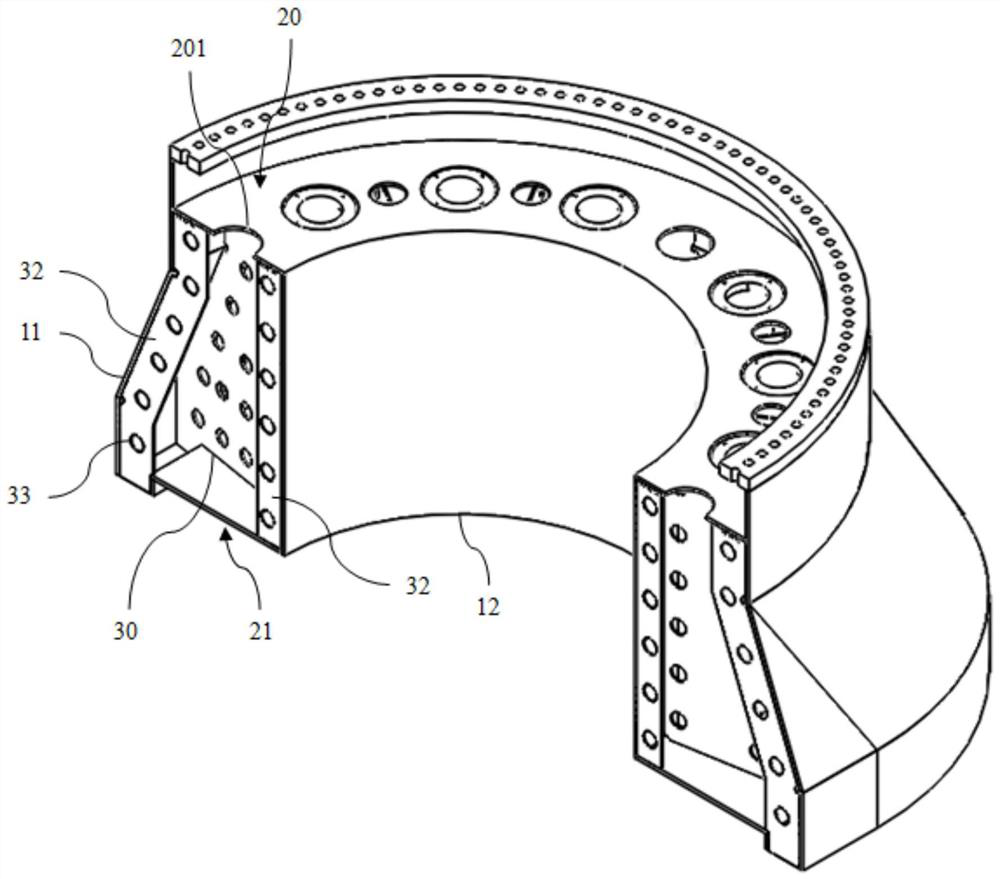

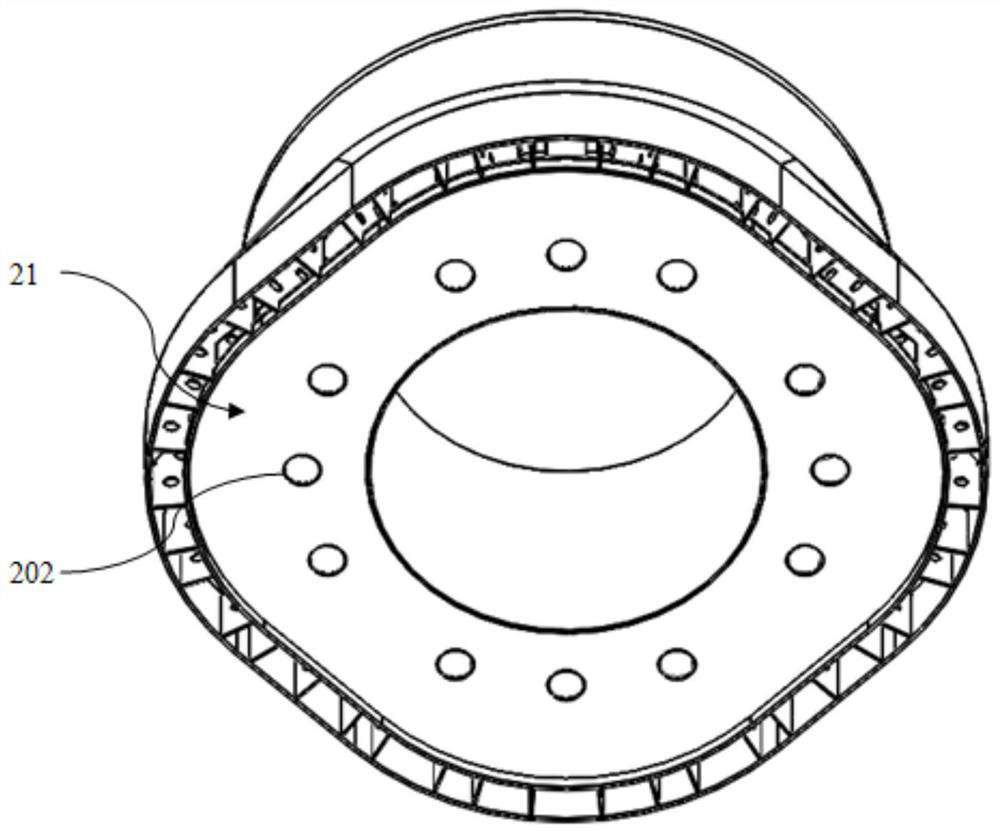

[0031] see Figure 1 to Figure 4 , the present invention provides a steel-concrete composite structure transition section for a wind power tower, including a steel structure main body 10 and concrete, the concrete is poured in the inner cavity of the steel structure, and works in conjunction with the steel structure main body, which not only greatly improves the mechanics performance, and improve the construction difficulty.

[0032] Specifically, the steel structure main body 10 includes an outer steel shell 11 and an inner steel shell 12 nested therein. The outer steel shell 11 is arranged around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com