Concrete Steel Tube Column-Steel Beam External Diaphragm Joint Structure and Its Construction Method

A technology for concrete-filled steel tubular columns and concrete structures, which is applied to building components, building structures, earthquake-proof and other directions to achieve the effects of enhanced combined action, reasonable design, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

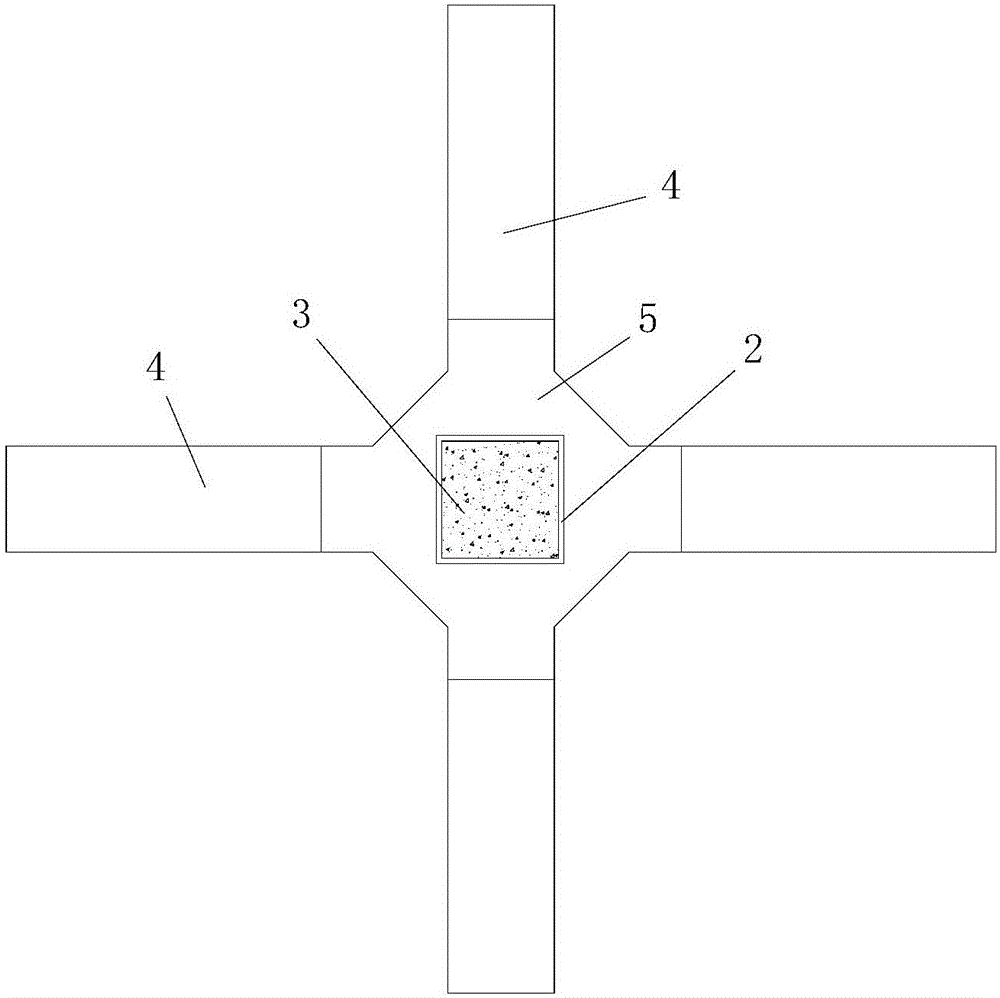

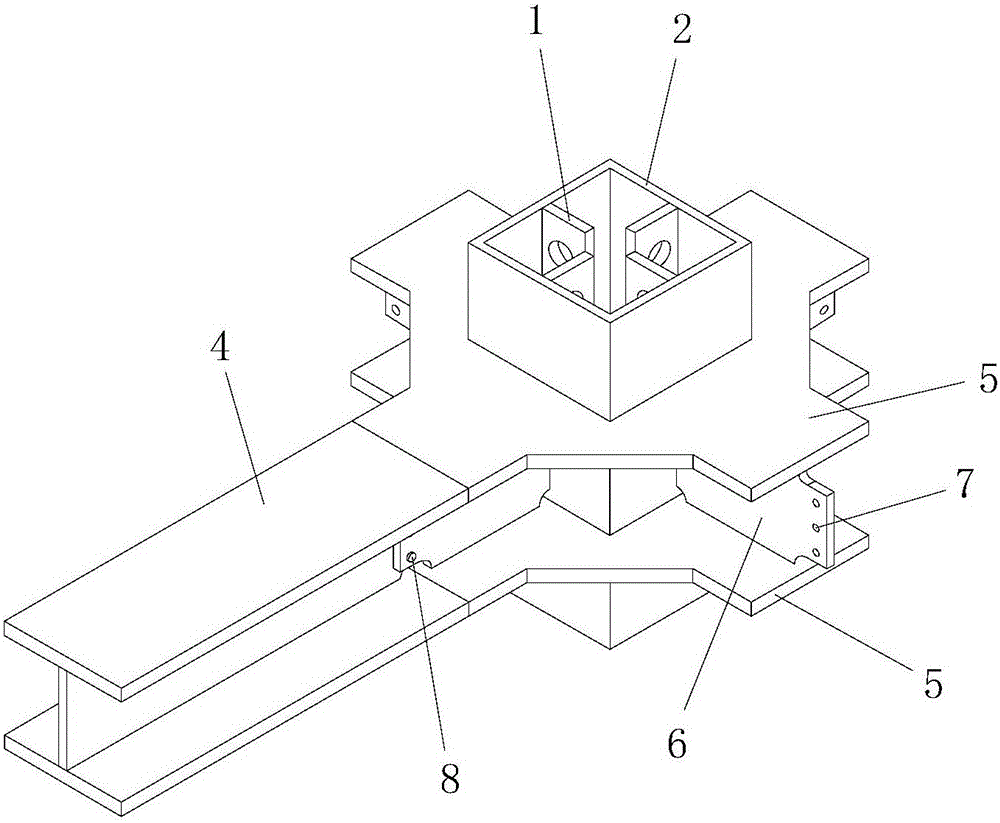

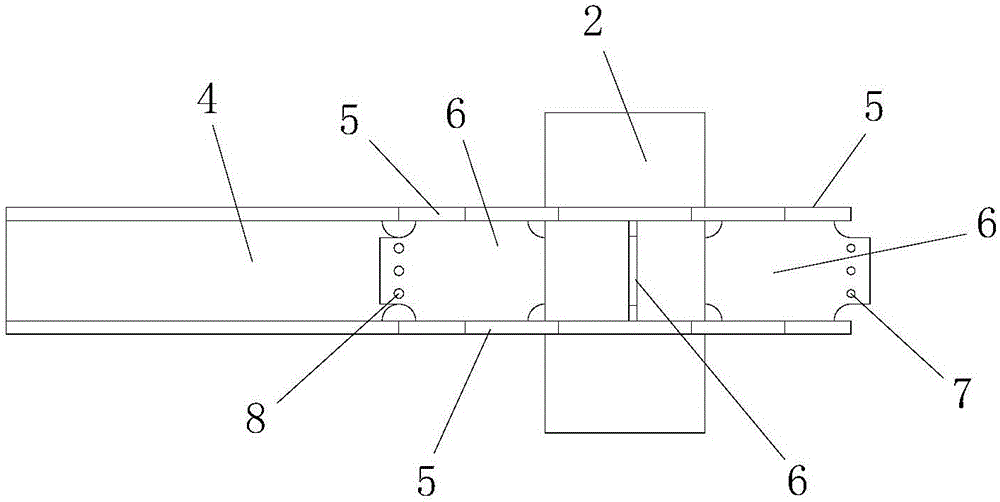

[0061] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The concrete-filled steel tube column-steel beam outer diaphragm joint structure shown includes a steel tube concrete column, a steel beam 4 located outside the steel tube concrete column, and a beam connected between the steel tube concrete column and the steel beam 4 The column connection structure, the steel pipe concrete column and the steel beam 4 are arranged vertically.

[0062] The concrete-filled steel pipe column includes a rectangular steel pipe column 2, four groups of longitudinal ribs 1 with openings arranged on the four inner walls of the rectangular steel pipe column 2, and a core concrete structure 3 filled in the rectangular steel pipe column 2. The perforated longitudinal ribs 1 are all poured in the core concrete structure 3, and the structure and size of all perforated longitudinal ribs 1 in the four groups of perforated longitudinal ribs 1 are the same; each group of perforated l...

Embodiment 2

[0104] In this example, if Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the adopted CFST column-steel girder outer diaphragm node structure is different from that of Embodiment 1 in that: the web connecting plate 6 and the steel girder 4 are connected by welding, and the four The perforated longitudinal ribs 1 are respectively arranged in the middle of the four inner side walls of the rectangular steel pipe column 2 .

[0105] In this embodiment, the structure and connection relationship of the remaining parts of the steel pipe concrete column-steel beam outer diaphragm joint structure are the same as those in Embodiment 1.

[0106] In this embodiment, the construction method of the steel pipe concrete column-steel girder external diaphragm joint structure is different from that in Embodiment 1 in that: when connecting the steel girders in step 3, the steel girder 4 and the web connection plate 6 are connected by Connected by welding.

[0107] In this embodi...

Embodiment 3

[0109] In this example, if Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, the adopted CFST column-steel girder outer diaphragm node structure is different from that of Embodiment 1 in that it also includes m stirrups 9 arranged on the four groups of longitudinal ribs 1 with openings from top to bottom. , the stirrups 9 of the m road are arranged in parallel, and the stirrups 9 of the m road are arranged perpendicular to the rectangular steel pipe column 2, wherein m is a positive integer and m≥3; the stirrups 9 of the m road are all poured in the core Inside the concrete structure 3;

[0110] The number of through holes 10 opened on the strip steel ribs is m, and the stirrups 9 of the m roads are respectively from the m through holes 10 opened on each of the strip steel ribs. through. Such as Figure 15 As shown, the through hole 10 is a slot-shaped hole.

[0111] In this embodiment, m=5.

[0112] During actual construction, the value of m can be adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com