Solderless node connector for steel-concrete composite structure

A technology of node connectors and combined structures, which is applied in the direction of building construction and construction, can solve the problems that the structural design is greatly affected by the architectural design, the quality of concrete construction, and the uneven force of the well-shaped beams, etc., so as to reduce the workload of on-site welding , The construction quality is easy, the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

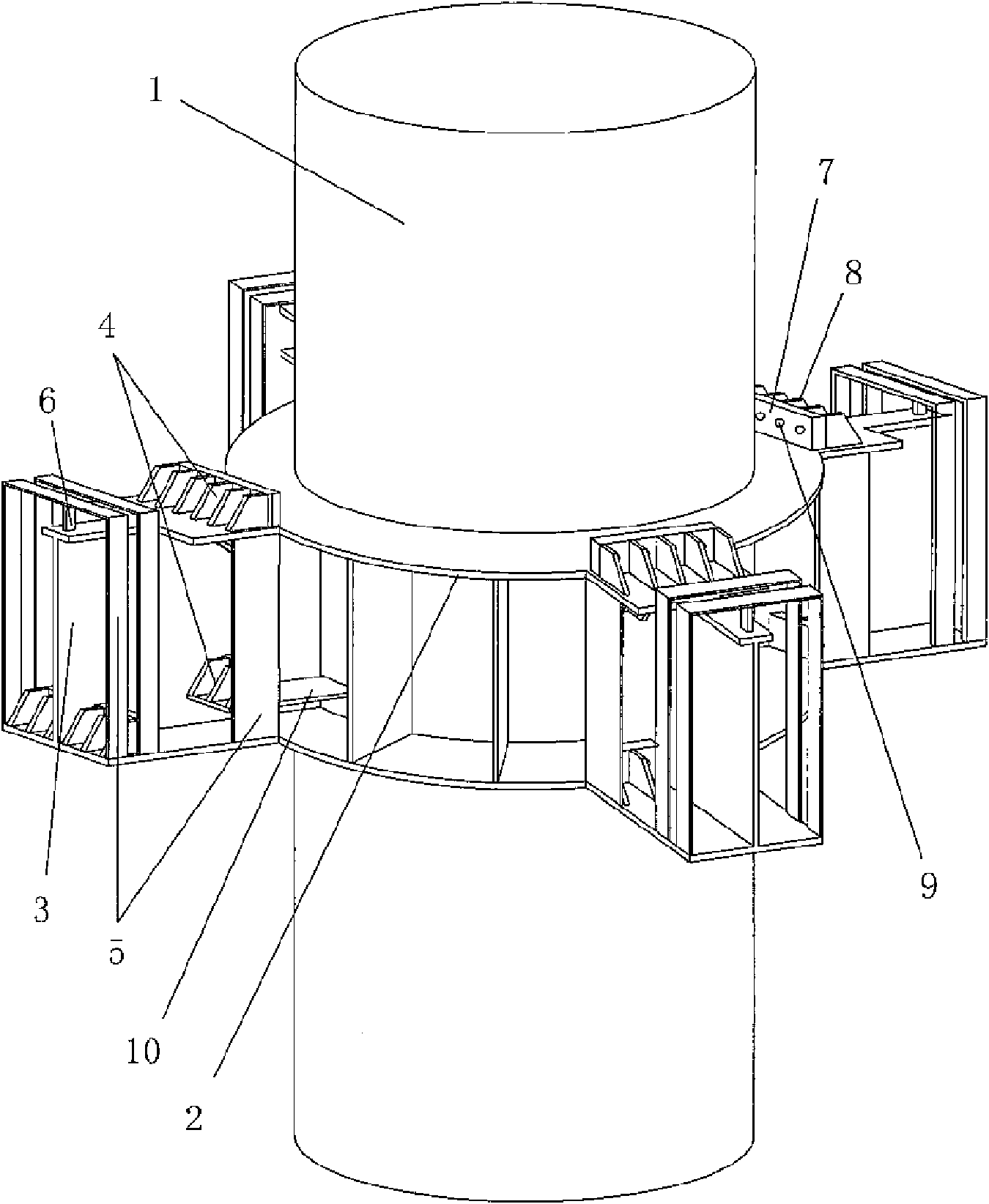

[0015] Example 1, see figure 1 , a steel-concrete combined structure non-welded node connector described in this embodiment, including a steel column 1, a ring plate 2 and four corbels 3, the ring plate 2 and the steel column 1 are welded together, and the uniform and symmetrical distribution The four corbels 3 are respectively welded with the ring plate 2 or processed as a whole, and a steel bar connector 4 for installing steel bars is designed on the top and bottom plates of each corbel 3 . The steel bar connector 4 includes a mounting plate 7, on which more than one through hole 9 is designed for the penetration of steel bars (the number and diameter of the through holes 9 depend on the number and specifications of the steel bars in the concrete structure) . The reinforcing bar connector 4 includes more than two stiffening plates 8 (the number of stiffening plates 8 is equal to the number of steel bars in the concrete structure plus 1) that acts as force transmission. The ...

Embodiment 2

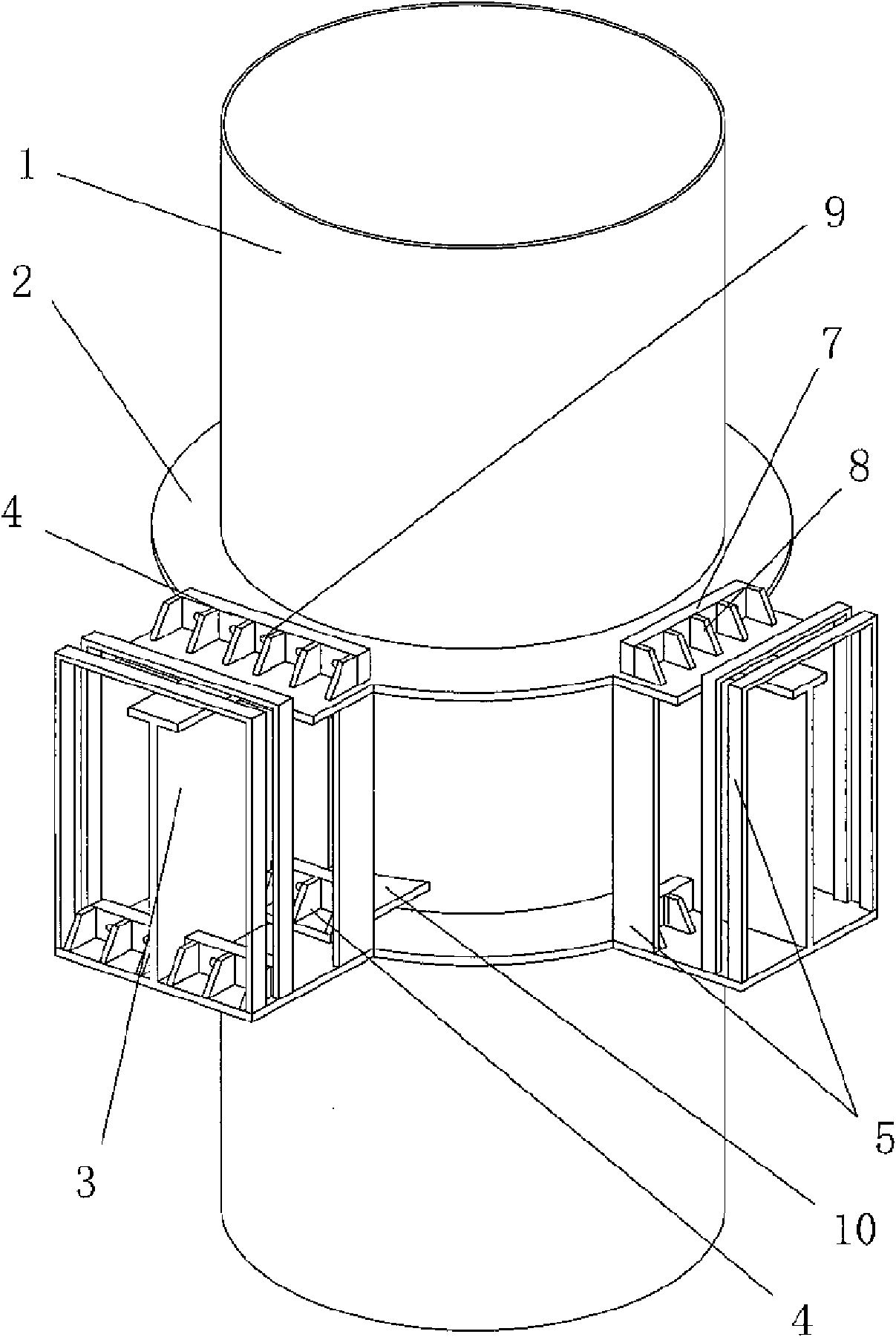

[0016] Example 2, see figure 2 , a steel-concrete combined structure non-welded node connector described in this embodiment, comprising a steel column 1, a ring plate 2 and two corbels 3, the ring plate 2 and the steel column 1 are welded together, and the two corbels 3 are respectively welded together with the ring plate 2 or processed as a whole, and steel bar connectors 4 for installing steel bars are designed on the top plate and the bottom plate of the corbel 3. The steel bar connector 4 includes a mounting plate 7, on which more than one through hole 9 is designed for the penetration of steel bars (the number and diameter of the through holes 9 depend on the number and specifications of the steel bars in the concrete structure) . The reinforcing bar connector 4 includes more than two stiffening plates 8 (the number of stiffening plates 8 is equal to the number of steel bars in the concrete structure plus 1) that acts as force transmission. The stiffening plates 8 are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com